Custom Into Pare-Chocs Molding Processing Companies OEM ABS Hot Runer Plastic Injection ...

SHENZHEN CEMAL ENGINEERING CO., LIMITED- Plastic Material:Various Plastics Like ABS,PP,PA

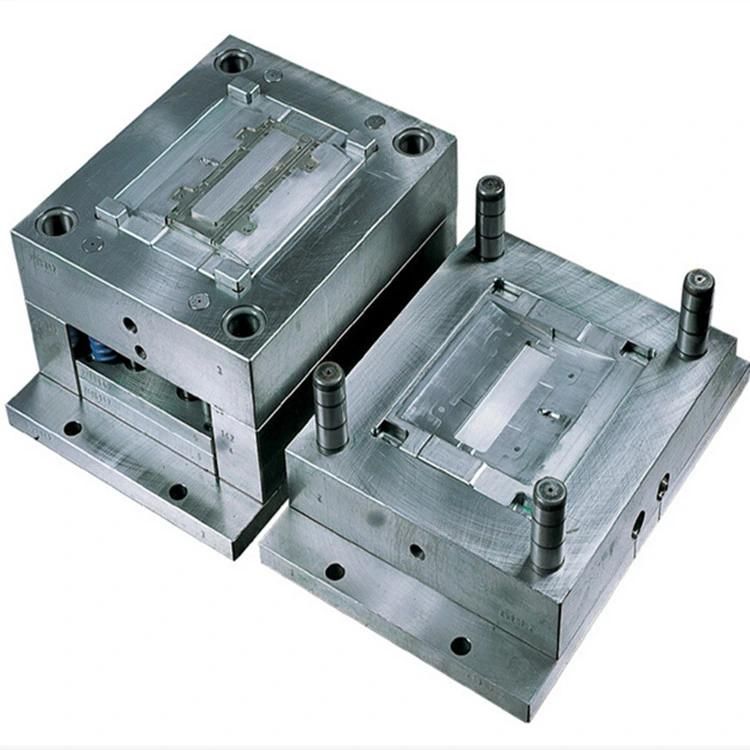

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Warranty:2 Years

- Process Combination Type:Single-Process Mode

Base Info

- Specification:According to different requirement

- Transport Package:Wood Case, or as Customer Requirement

- Customized:Customized

- Certification:ISO

- Installation:Fixed

- Design Software:CAD,Proe,Ug,Solidworks

- Runner:Hot Runner,Cold Runner

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Model NO.:mould-08b

- Trademark:Can be customized

- Origin:Shenzhen, Guangdong, China

- Production Capacity:50sets,Month

Description

Basic Info.

Model NO. mould-08b Application Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware Runner Hot Runner/Cold Runner Design Software CAD/Proe/Ug/Solidworks Installation Fixed Certification ISO Customized Customized Transport Package Wood Case, or as Customer Requirement Specification According to different requirement Trademark Can be customized Origin Shenzhen, Guangdong, China Production Capacity 50sets/MonthProduct Description

Cemal,The Molding WizardsServices:

- Project Evaluation;

- Product Design;

- Electronic Design & Engineering;

- Mechanical Design & Engineering;

- Prototype Design & Engineering;

- Design for Manufacturing;

- Manufacturing Coordination;

- Mould design;

- Manufacturing;

- Second processing;

- Assembly and etc.,

- One-stop services for plastic parts.

Products Range:Automotive Parts,Industrial Parts,Communication Parts,Household Appliances Parts,Electronics Parts,Cosmetics Parts,Computer Peripherals Parts,Medical Parts,Precision Parts,Equipment Parts...

Mold Type:In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould

Advantages:

1. Competitive Price

2. Quick Delivery time(2-4 weeks)

3. ISO Certificated with the srtictest quality control system

4. 23 Years OEM&ODM Mould-making and Plastic processing experience

5. Advanced equipment and Skilled workers

OEM & ODM FACTORY

Research >>> Electronic Design >>> Indusfrial And Mechanical Design >>> Moulds Tooling >>> Moulding >>> Secondary Process >>> Assembly

For More Information, Please Make An Inquiry!

Product Description:

| Software | UG, PRO/ENGINEER, CAD, CAXA, Moldflow |

| Steel For Mould | 45#, 50#, P20, H13, 718, 718H,738, NAK80, S136, SKD61 or customer-designated brands |

| Required Time To Finish Mould | 16 days for expediated service; 30 days for normal case |

| Target Mould Life | more than 0.5-1 million |

| Estimated Injection Molding Production Cycle | Conventionally 6-30 seconds, try to design automatic drop to reduce manual trials and injection molding processing costs. |

| Mold Cavity | Single/double/multiple |

| Mould Surface Finish | Industrial polishing grade, electroplating, high gloss, three-dimensional ripple |

| Mould Manufacturing Process | Technical requirements determination - product review - material preparation plan design - ordering materials - 3D design - mold structure and process review - drawing release - mould frame/core/ fittings/electrode processing - process inspection - assembly - test mould - modification - production - shipping - after-sales service. |