Electronic Parts High Precision Hot Runner Plastic Injection Mold Make in China

Dongguan Howe Precision Mold Co., Ltd.- Process Combination Type:Progressive Die

- Plastic Material:ABS, PC, PMMA, POM, PA (Nylon), PP, PBT, etc.

- Mould Cavity:Single Cavity , Multi-Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Mirror Polish, Texture, Silk-Screen Printing, etc

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Base Info

- Specification:OEM

- Transport Package:Export Standard Wooden Case for Mould

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Insert

- Design Software:Ug, Proe, Autocad

- Runner:Hot Runner or Cold Runner

- Model NO.:HW-201006-2

- Trademark:HOWE,OEM

- Origin:China

- HS Code:8480719090

- Production Capacity:300-400 Sets,Year

Description

Basic Info.

Model NO. HW-201006-2 Runner Hot Runner or Cold Runner Design Software Ug, Proe, Autocad Installation Insert Certification ISO Standard DME Customized Customized Transport Package Export Standard Wooden Case for Mould Specification OEM Trademark HOWE/OEM Origin China HS Code 8480719090 Production Capacity 300-400 Sets/YearProduct Description

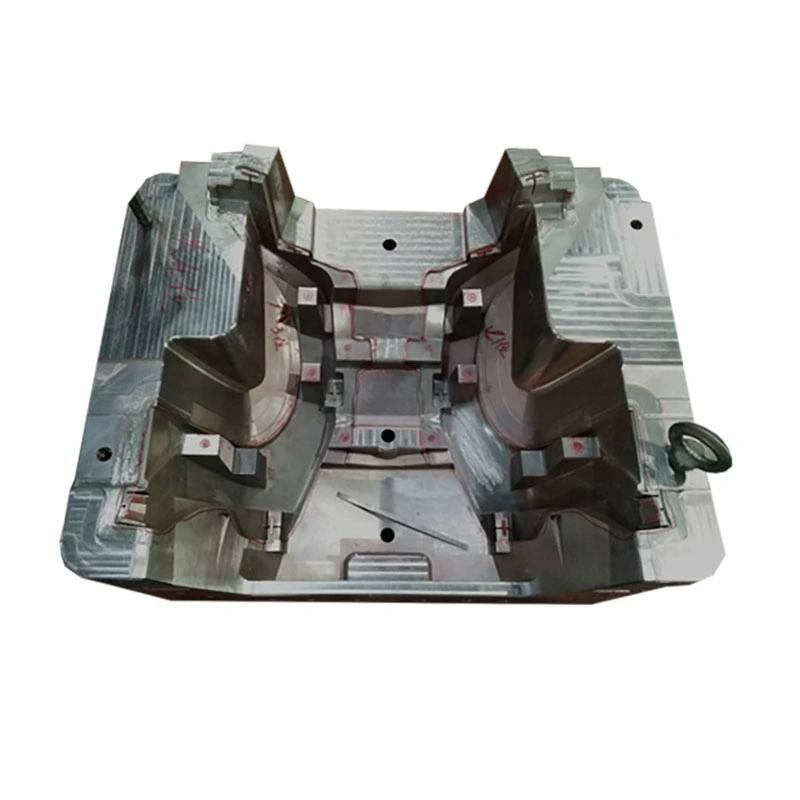

High Precision Hot or Cold Runner Plastic Injection Mold MakerMold Information:

| Manufacturing | Electronic Parts Plastic Injection Mold |

| Material | Mold:718H, NAK80, S136H, DIN1.2344,LKM2083,LKM2344,8406,8407,S136,LKM2767 etc. |

| Design Software | UG,PROE,CAD,Solidworks,etc |

| Cavity Variety: | One-stop solution, Multi-cavity mold, Family plastic mold, Hot runner plastic mold |

| Quality Control | ISO14001:2008 system |

| Business Scope | Mold and parts designing and making, Parts machining, Injection molding, CNC prototype manufacturing |

| Mold Processing | CNC EDM machine processing then assembly and trial |

| General Size | According to your 3D drawings |

| Manufacturing Machines | CNC,EDM,MILLING,WIRE EDM,etc |

| Runner | Hot Runner/Cold Runner |

| Plastic Mould life | 300,000-1,000,000 shots |

| Ejection System | Ejector pin or ejecting block |

| Mold Standard | Domestic standard, HASCO standard, DME Standard, MasterFlow Standard |

| Mold Making Time | 15-35 days |

| Plastic Material | ABS,PP, PC, PS, PE, PET, POM, PA,PU, PVC, PEI,HIPS, PMMA etc. |

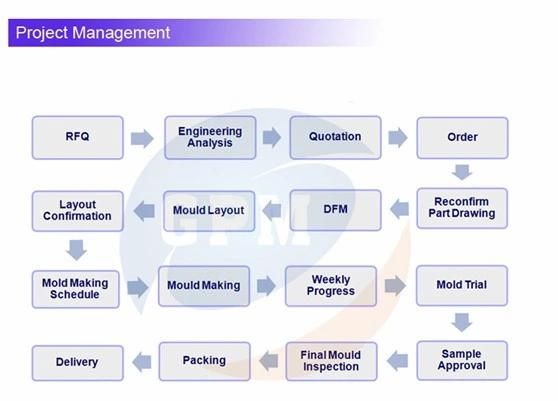

Tooling Developing Procedure:

1. Quotation: We need your require clearly

2. Negotiation: Material, cavity, price, delivery time, payment term, etc.

3. Order: According to your own design or choice our design

4. DFMEA: Deign failure mold & Effect analysis to reduce risk

5. Mold design: 2D/3D drawing

6. Cutting Tooling Notice: After customer approve the mould design will start making mould

7. Weekly Report: We will update the mold schedule every week

8. Sample Confirm: Send you samples to confrrm it, if not satisfied by customers. We modify the mould.

9. Delivery Mold: Delivery the mould after customer approve sample and arrange shipment

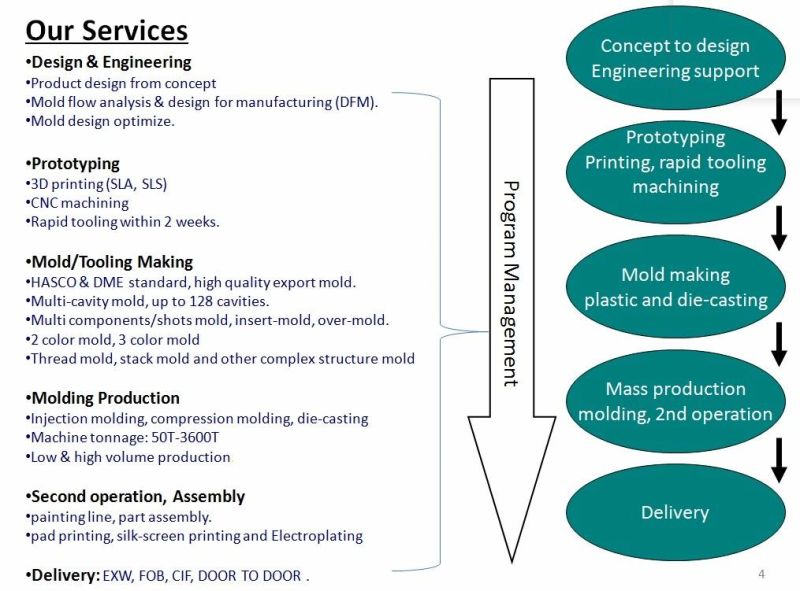

Our Advantages

| 1. | R&D (Design according to client's drawing and requirements) |

| 2. | Professional mold manufacturer |

| 3. | Molding parts, such as led lamp parts, car parts, auto accessories, electronic components, medical products, office appliance, etc |

| 4. | Various materials and short lead-time |

| 5. | High-quality steel and long mould life. |

| 6. | We can supply "one-stop" service with molds opening, injection, painting, screen printing, assembly and good after-sales |

| 7. | Full set machines for mold making and products injection |

| 8. | Mould's steel as per customers' requests such as NAK80, S1369(H),2738, 718, 738 and etc. |

| 9. | Various used plastics: ABS,PP,PE,POM,PA6(66)+GF,PC,PMMA,HIPS,GPPS and etc. |

| 10. | Various colors available, if they could provide us the color card number. |

| 11. | Certifications Authorized: IATF16949 |

Our workshop

Our team:

Customer Visit:

FAQ About Plastic injection mold

Q1: What kind of molds do you make?

A1: We are mainly making plastic injection mold and die-casting mold.

Sometimes we also make rubber molds according to our customer's requirements.

Q2: Do you build hot runner plastic moulds?

A2: Yes. We build hot runner Plastic Moulds and specialized in many different systems, such as DME, Master,Mastip, Hasco, Yudo, Incoe, Husky,etc.

The manifold recommended for your tool is selected to meet your individual needs.

Q3: What types of files do you accept (drawings)?

A3: With our CAD systems we can accept the following files:

STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q4: What kind of steel do you use for plastic mouldings?

A4: We can use any type of steel appointed by customer or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q5: Can you provide the steel certificate and heat-treatment certificate?

A5: Yes, We can provide steel certificate or hardness certificate to prove.

Q6: Can you make the texture/text/heat-treatment/nitriding for the injection mold plastic?

A6: Yes, As a plastic mold factory, we have long-term cooperated subsidiary factories that do those processes.

They are professional and well reputed in our local market.

Q7: How long is the lead-time for a plastic injection mold?

A7: It all depends on the mold's size and complexity. Normally, the lead time is 25-45days.

If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q8: Do you make spare parts for your customer?

A8: Yes, we will provide spare parts for the mold if needed or required by clients.

Q9: How do you pack the plastic moulds?

A9: We pack the plastic moulds with a wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid moisture.

Third step: We put this plastic film packed mold in a wooden box, and fix it to avoid any movement.