-

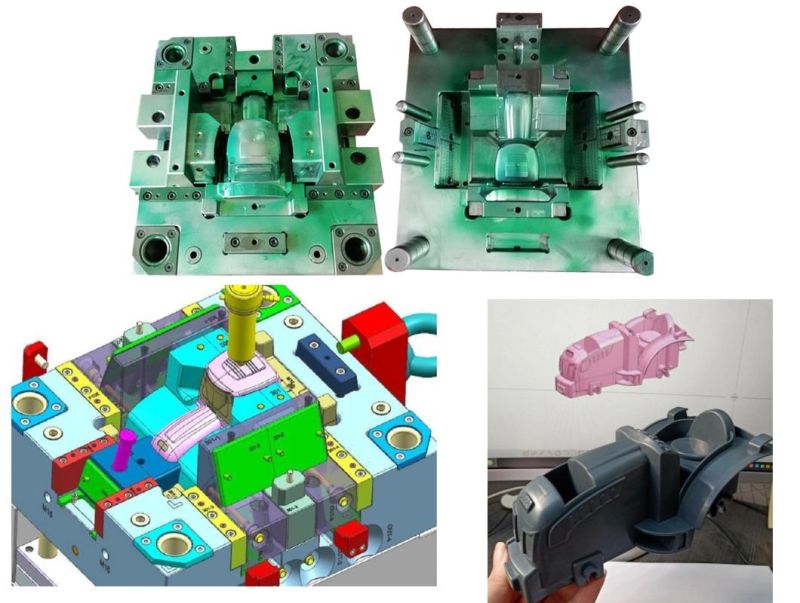

Dongguan Custom High Quality Products Mould for Bracket.

Production DetailsProductnameDongguan custom high quality products mould for bracket.MoldshapingPlasticInjectionmolding,MoldbaseLKM;HASCO;DME,etcMoldmaterialNAK20,S136,P20.718H,738H,45#,etcMoldcavitySingleorMultiTolerance+/-0.001mmFinishAnodized,Polish,Silk-screen,Painting,etcSpruegateHot/coldrunner

-

Dongguan Professional OEM Injection Plastic Mould for Plastic Ring.

Production DetailsProductnameDongguan professional OEM injection plastic mould for plastic ring.MoldshapingPlasticInjectionmolding,MoldbaseLKM;HASCO;DME,etcMoldmaterialNAK20,S136,P20.718H,738H,45#,etcMoldcavitySingleorMultiTolerance+/-0.001mmFinishAnodized,Polish,Silk-screen,Painting,etcSpruegateHot

-

PP Plastic Tooling Injection Mold for Thin Wall Cover

Mould informtionInjection mold standardHASCO,DME,MISUMI,China lKM Standard.Please provide2D, 3D, samples, or the size of the multi-angle pictures.Mould material45#, 50#, P20, 738, 738H, 718, 718H, NAK80, 2316, 2316A, S136 etc.Product materialABS,PA6,PA66,PP,PC,TPU,POM,PBT,PVC,TPE,TPV,TPO,TPR,EVA,LDP

-

Custom Injection Molding Products Plastic Molds for ABS Electronic Parts

BACK TO HOMEPAGE FOR MORE PRODUCTS!

-

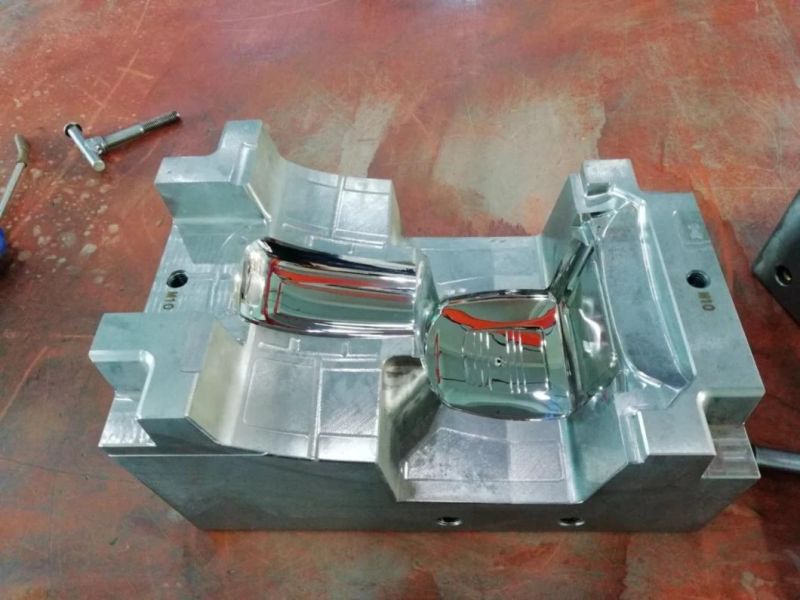

Plastic Injection Filter Pipe Mould

Product NamePlastic Injection Filter HousingmouldProduct materialPP+GFCore&Cavity Steel718Steel hardness:HRC34-38Mould StandardDMECavity NumberONEInjection SystemDirectGateEjector SystemStripper Plate+oil cylinderCycle Time45STooling lead time60DAYSMould life500,000SHOTSQuality assuranceSGSOur A

-

Plastic Injection Filter Cap Mould

Our Advantage1. High quality2. Reasonable price3. On time delivery4. Good After-sale service5. Strict quality control6. All the mould are automotic.Offer youIn-time response on letters, telephone calls or faxIn-time supply the quotation and mould designsIn-time communication on the technical pointsI

-

Custom BPA Free Plastic Storage Container for Home Organizer

COMPANY PROFILEHOW TO ORDER FROM HOWE?1. Inquiry-Professional quotation.2. Confirm the price. lead time. artwork. payment term etc.3. Howe sales send the Proforma Invoice with Howe company seal.4. Customer make the payment for deposit and send us Bank receipt.5.Initial Production Stage-Inform the cl

-

Plastic Injection Mould Tooling for Motorcycle ABS Clutch Cover Accessories

Process of making moulds1.Sample/DrawingAfter receiving your detail information like 2D & 3D drawings or sample for reference, will pass to the R&D team to do Moldflow analysis.2.NegotiationMaterial, cavity, price, delivery time, payment term etc.3.Place Orderwhen all terms are agreed by bot