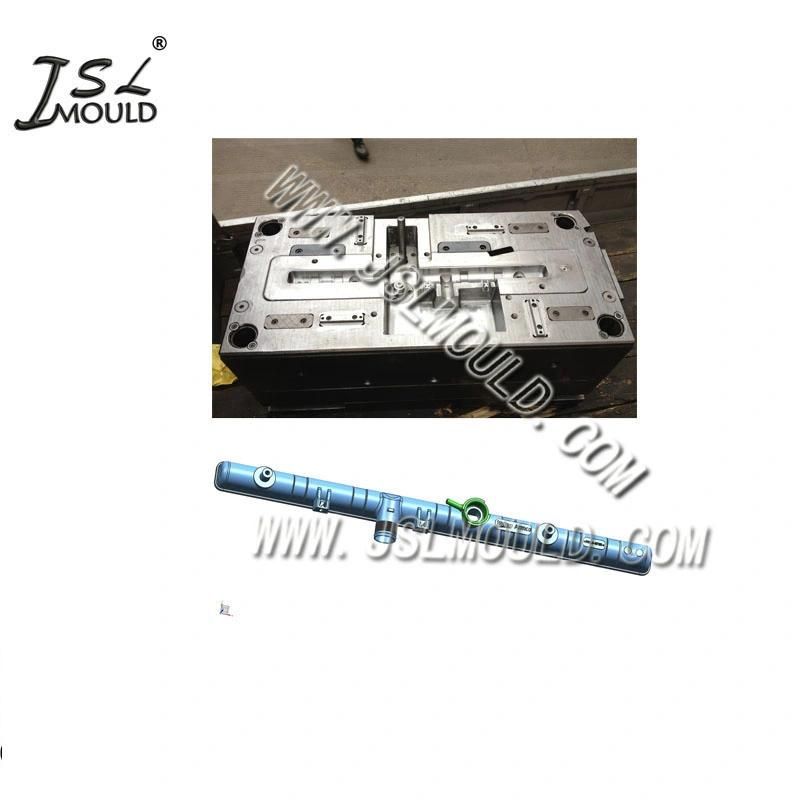

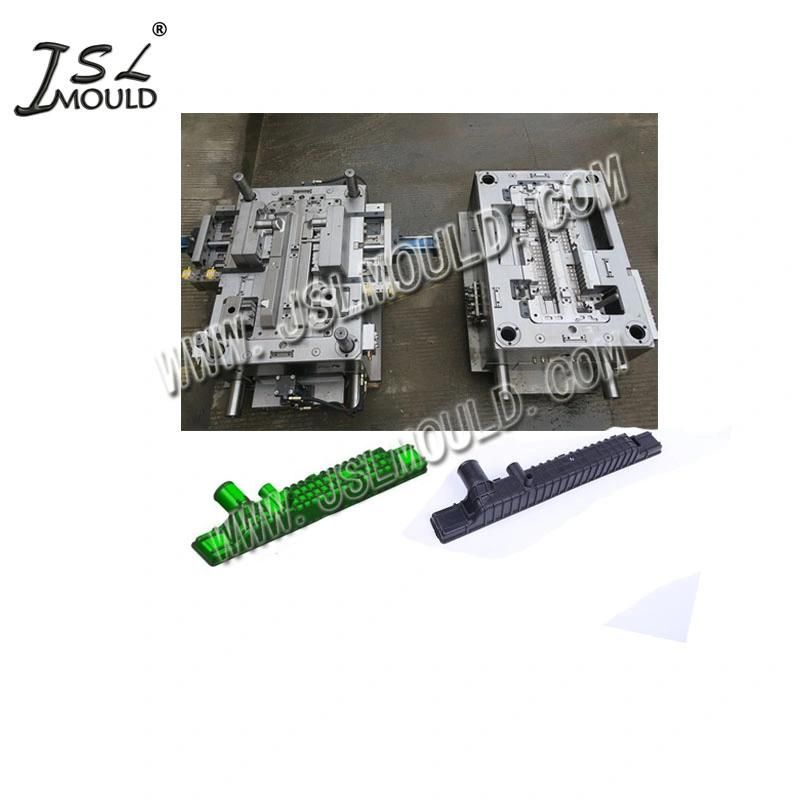

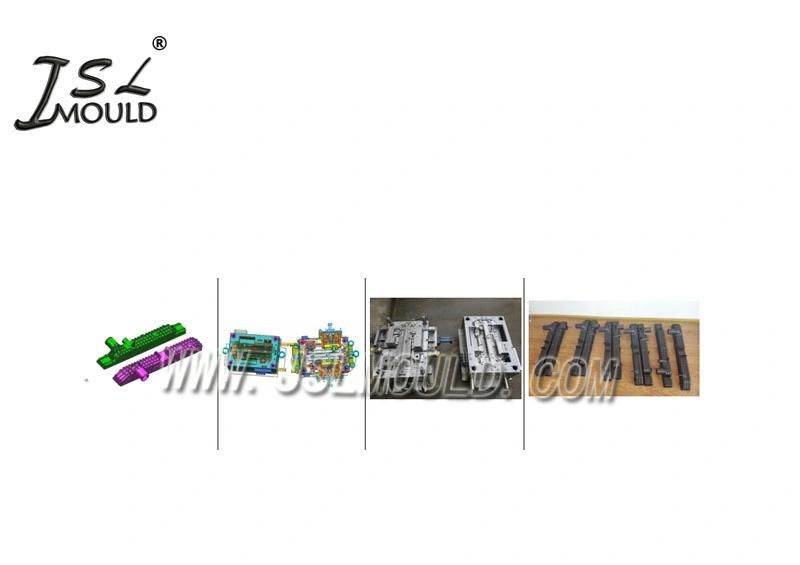

Rich Experienced Making Plastic Car Radiator Tank Mould

Taizhou City Huangyan Beiwei Mould Industry Co., Ltd.- Plastic Material:PA66+GF

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Process Combination Type:Single-Process Mode

- Application:Car

Base Info

- Sample:Avaliable

- Design:7days

- Provide:3D Printing, Moldflow Analysia, Dfm Report Service

- Machine Equipment:CNC,EDM,Wire Cutting Machine,Drilling,Grinding

- Mould Operating Mode:Automatically by CNC

- Surface Treatment:Polish,Texture,Chromed

- Mould Quality Control:by Professional QC in House Machine

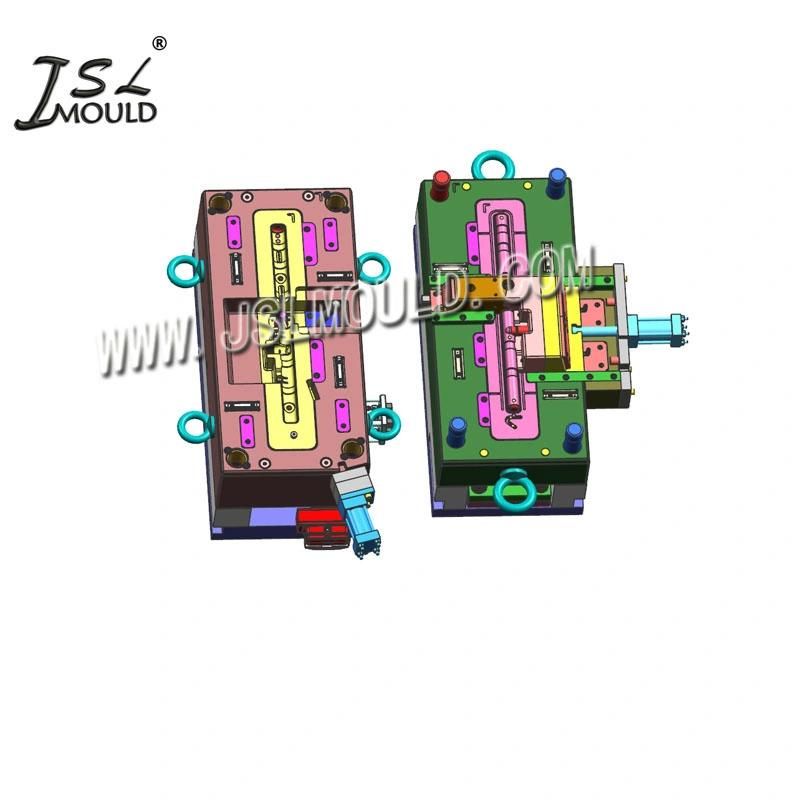

- Mould Cooling System:by Experienced Designer

- Heat Treatment:Nitriding

- Mould Life:300,000-2000,000shots

- Mould Base:S50c,C45

- Customized:Customized

- Standard:Dme,Lkm,Hasco

- Certification:CE, ISO

- Installation:Fixed

- Design Software:Ug, Proe, Solidworks CAD, Ect

- Runner:Cold,Hot

- Model NO.:JSL-T1777-2

- Mold T1 Sample:50days

- Mould Report:7days,Time

- Aftersale Service:Yes

- Quality Guarantee:2 Year

- Transport Package:Wooden Crate

- Trademark:JSLMOULD

- Origin:Taizhou, China

- HS Code:8480719090

- Production Capacity:500 Sets Molds,Year

Description

JSL Mould Quality Control

For the Q/C of mould, there are 3 steps:

1. Mould Material Q/C

- Mould Steel Checking(Hardness, flaw detection)

- Mould Standard Spare Parts Checking(hardness, size, flaw checking)

2. Mould Making Process Q/C

- design checking (part design, mould design, mould engineering drawing)

- checking each part of mould's size after machining, according to 2D drawing

- mould testing(check mould running condition)

3. Check with customer's requirement again before mould shipping.

For more information, please contact with us freely.