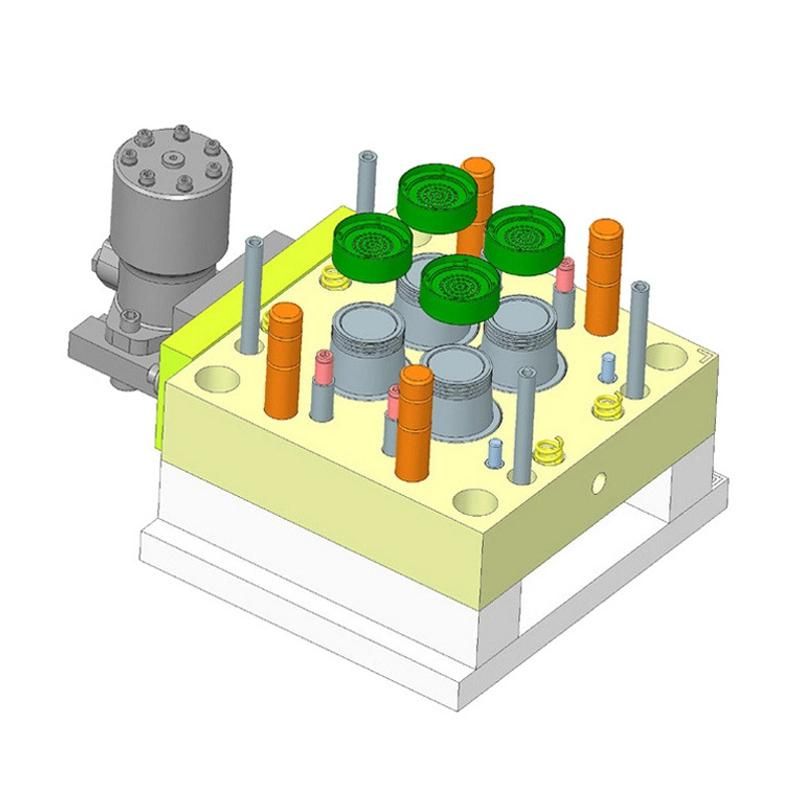

Plastic Molding Die

DONGGUAN MITIME INDUSTRY LTD- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware, Resin Craft or Metal Carfts

- Plastic Material:Both Have

- Shaping Mode:Plastic Molding Die

- Surface Finish Process:Resin Craft or Metal Carfts

- Warranty:2year

- Runner:Cold Runner

Base Info

- After-sales Service:2year

- Customized:Customized

- Certification:TS16949, ISO, FDA

- Design Software:UG

- Model NO.:mitime007

- Origin:Dongguan City Guangdong Province China

- Production Capacity:500

Description

Basic Info.

Model NO. mitime007 Design Software UG Certification TS16949, ISO, FDA Customized Customized After-sales Service 2year Origin Dongguan City Guangdong Province China Production Capacity 500Product Description

One for molding, extrusion, injection, blow molding and low foaming molding composite plastic mould, which mainly includes composite substrate by concave die, die components and die combination of card board with variable cavity die, the punch combination of substrate and convex die components, combination punch card board, cutting mould components and side sections of composite slab has a flexible convex mold core. Coordinate change of convex and concave die and auxiliary forming system. Can process different shapes, different sizes of the series of plastic parts.

All kinds of tools and products used in our daily production and life, from the base and body shell of machine tools to the shell of an embryo head screw, buttons and various household appliances, are closely related to the mold. The shape of the mold determines the shape of these products, and the processing quality and precision of the mold also determines the quality of these products. Because of the different materials, appearance, specifications and uses of various products, molds are divided into casting molds, forging molds, die-casting molds, stamping molds and other non-plastic molds, as well as plastic molds.