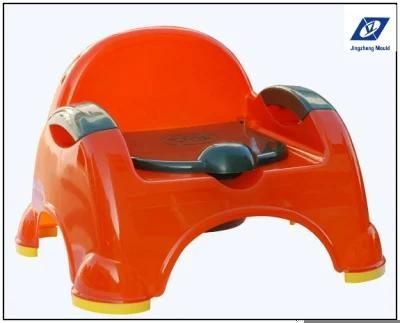

Plastic Children Chair Mold

Zhejiang Taizhou Huangyan Jingzheng Mould Co., Ltd.- Plastic Material:HDPE

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Warranty:12 Months

- Process Combination Type:Compound Die

Base Info

- Transport Package:Wooden Case

- Material:PP

- After-sales Service:12 Months

- Customized:Customized

- Standard:HASCO

- Certification:ISO

- Installation:Mobile

- Design Software:AutoCAD

- Runner:Hot Runner

- Application:Household Appliances

- Model NO.:JZ

- Specification:ISO9001-2000

- Trademark:JZ

- Origin:China

- HS Code:8480719090

- Production Capacity:100 Sets,Month

Description

Basic Info.

Model NO. JZ Application Household Appliances Runner Hot Runner Design Software AutoCAD Installation Mobile Certification ISO Standard HASCO Customized Customized After-sales Service 12 Months Material PP Transport Package Wooden Case Specification ISO9001-2000 Trademark JZ Origin China HS Code 8480719090 Production Capacity 100 Sets/MonthProduct Description

Plastic chair mold

High quality with competitive price, we are using Chinese, Korean, Japan, Germany Standard to make moulds according to our customers requirement, the products' dimension range from 25mm to 630 mm.

| Name | Plastic children chair mold |

| Plastic material | PP |

| Steel of Cavity & Core | 718/P20 |

| Steel of Mouldbase | S50C. LkM standard^ etc |

| Nos of Cavity | Customized |

| Hardness of Cavity & Core | 42-45HRC |

| Hardness of Wear Parts | 42-48HRC |

| Core pulling system | Motor /oil cylinder/ stripping plate, angel pin^ etc |

| Mould Accessories | DME/HASCO Standard ^ |

| Cooling system | In core baffle cooling and in cavity plate chain drilling type cooling |

| Surface finish | Diamond polish, |

| Molding life | 500, 000shots |

| Runner | Cold |

| Delivery time | 55 work days |

| Packing | wooden case |

| Payment | T/T L/C |

Jingzheng Advantage:

Mould parts:

Our certificates:

Our patents:

About us:

Packing and shipping: