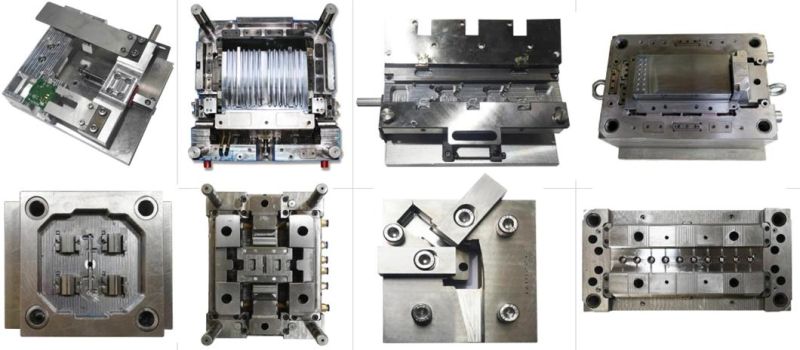

Customized Silicone Mould Stamping Die Plastic Injection Molding for ABS Handle

Qingdao Chuangyu Precision Machinery Co., Ltd.- Surface Finish Process:Polishing

- Mould Cavity:Single Cavity

Base Info

- Transport Package:Cartons, Wooden Pallet or Customized

- Logo Method:Laser Engraving, CNC Engraving Ect

- Surface Treatment:Anodizing, Powder Coating ,Painting Ect

- Port:Qingdao China

- OEM/ODM:Yes

- Customized:Customized

- Standard:HASCO

- Certification:CE

- Installation:Fixed

- Design Software:UG

- Runner:Cold Runner

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Model NO.:CMP01

- Specification:up to design

- Trademark:Chuangyu

- Origin:China

- HS Code:8480419000

- Production Capacity:5000pieces,Month

- Package size per unit product:15.00cm * 7.50cm * 5.50cm

- Gross weight per unit product:0.850kg

Description

Factory:

We are a professional manufacturer specialized in custom products, such as plastic injection mold, stamping die, rubber mold, silicone mold, machining parts... according to client's drawings or samples.

We could control the quality and the cost very well by our own equipments, such as grinding machine, milling & turning machine, CNC center, wire cutting, bending machine, stamping machine, injection machines...ect

1: We make almost all the material to meet client's different needs, such as ABS/POM/PVC/PP/PA66/TPE/Aluminum/Stainless steel/Brass/HSS/Brass ect.

2: Surface treatment: anodizing, powder coating ,polishing, electrophoresis, chemical galvanizing etc.

3: Finish: polished,mirror polished,brushed, sandblasted, heat treatment etc.

4: Color: anodized(black,silver,blue,gold,red,green,pink etc.), painting(all colors) ect

5: Logo Method: laser engraving, CNC engraving, screen-printing etc.

Our professional and exellent workers:

All of our workers have more than 5 years experience and received professional training from Japanese company as to ensure the products quality.

We could control the price and quality very well by our own equipments, such as Grinding machine, Milling machine, CNC center, Wire cutting, Injection machine ect.

Certification:

Shipment:

We usually delivery the moulds and machinery parts by sea/DHL/FEDEX/TNT, according to the customers.

FAQ:

1.How can I get the quotation?

Please give us your drawing,quantity,weight and material of the product.

2.If you don't have the drawing,can you make drawing for me?

Yes,we are able to make the drawing of your sample duplicate the sample.

3.When can I get the sample and your main order time?

Sample time: 35-40 days after start to make mold.

Order time: 35-40 days, the accurate time depends on product.

4.What is your payment method?

T/T: 50% deposit,50%to be paid before shipment.

5.Which kind of file format you can read?

PDF, IGS, DWG, STEP, MAX

6.What is your surface treatment?

Including: powder coating, sand blasting, painting, polishing, acid pickling, anodizing, enamel, zinc plating, hot-dip galvanizing, electrophoresis, chrome plating.

7.What is your way of packing?

Normally we pack goods according to customers' requirements.