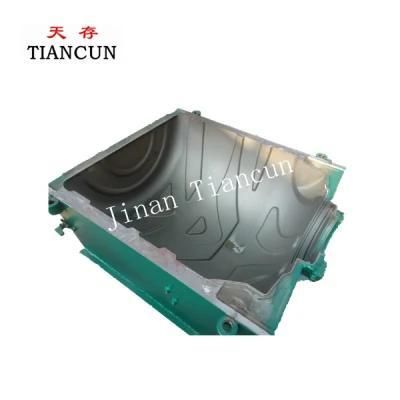

New Latest Technology Extruding Plastic Blowing Mould for Water Tanks

Jinan Tiancun Industry Equipment Co., Ltd.- Extrusion Blow Molding Mould Application Type:Machinery Manufacturing

- Method for Making Preforms:Extrusion Type

- Process Combination Type:Single-Process Mode

- Product Material:Steel

- Application:Commodity, Hardware, Electronic, Car, Home Use, Household Appliances

- Function:Abrasion Resistance

Base Info

- Specification:1000L

- Transport Package:Wood Packaging

- Cooling System:Best Cooling Cavities

- Mould Life:20 Years

- Condition:New

- Customized:Customized

- Warranty:12 Months

- Certification:ISO, CE, RoHS

- Model NO.:3000L

- Trademark:Tiancun

- Origin:Jinan City

- HS Code:8480790090

- Production Capacity:1000-1500PCS,Year

Description

Basic Info.

Model NO. 3000L Certification ISO, CE, RoHS Warranty 12 Months Customized Customized Condition New Mould Life 20 Years Cooling System Best Cooling Cavities Transport Package Wood Packaging Specification 1000L Trademark Tiancun Origin Jinan City HS Code 8480790090 Production Capacity 1000-1500PCS/YearProduct Description

500-3000L big capacity water tank blow mould

Products description:

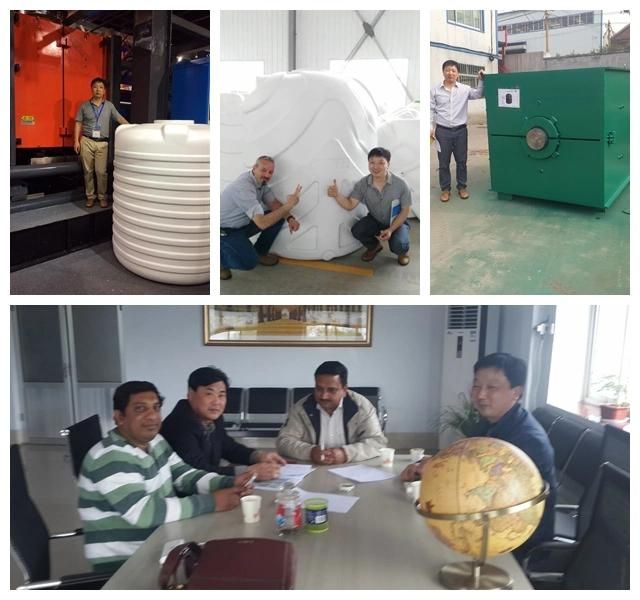

We are the biggest manufacturer of blow molding machine and blow mould for water tank in china.our company adopts CAD/CAM/CAE system to ensure effective control ,evaluate and machining of product design in the whole process of mold development.

All of our plastic mould is built according to our quality policy,and our operating policy is to encourage and train all employees to pursue never-ending improvement in the productivity and quality of the products we manufactured.

Design Tool:

Our company adopted international advanced system:CAD/CAM/CAE in mould design and manufacturing,our engineering and mould-making technology includes:

1.Pro/Engineering(3D Modeling).

2.SolidWorks(3D Modeling).

3.AutoCAD(2D Modeling).

4.Mold Flow Mold Advisor(Plastic flow/deform simulation)

5.MasterCAM(CNC Programming).

6.Unigraphics(CNC Programming).

7.CNC Machining Centers.

8.CNC EDM's(Electro Discharge Machining).

9.Wire-Cut Machines.

| Our advantage |

| 1.Design experience for many years,and water tank blow Mould professional design team. |

| 2. Production capacity of water tank blow Mould can supply 500--800 sets per year and delivery on time |

| 3.Good quality of water tank blow Mould and parts and good after service for long-term cooperation relationship. |

| 4.Good comunication skills and good service with customers,delivery on time according to customer requirement. |

| 5. Own CNC processing center and advanced production equipment of various water tank blow mould. |

| 6.Products advantage: excellent quality, long lifetime, competitive price & delivery timely |

plastic water tank blow mould

1. Customize design.

2. Own CNC processing center various advanced mould tooling equipment

3. Experienced designer team assure you of the perfect design.

4. Excellent quality,long lifetime, competitive price & fast delivery

| Mould material | 45# steel |

| Mould life | 100, 000-300, 000shots |

| Runner type | Hot / cold runner |

| Shaping mode | Plastic blowing mould |

| Cavity | Single |

| Package | Wooden case, carton or others |

| Mould lead time | 6-8 weeks |

| Available Plastic material | HMWHDPE,HDPE,PP, PVC, ABS, PE, etc |

With advanced management concepts and complete processing equipments,we are a one-stop service company gathering research,development,desgin,manufacture,processing and technical training. So that We have rich successful experience in making all kinds of moulds according to customer's requirements.