Progressive Stamping Mold, Single Process Mold with Customized Service

Qingdao Root Industrial and Trading Co., Ltd.- Process Combination:Progressive Die

- Manufacturing Technology:Automation Technology

- Technics:Cutting Die

- Processing Method:Punching and Shearing Mould

- Material:Matrix Steel

- Application:Household Appliances, Electronic, Hardware, Car, Commodity, Home Use

Base Info

- Specification:CE,SGS,RoSH

- Transport Package:Wooden Box

- Machine:Wire EDM

- Lead Time:20-30 Days

- Parts Detection Method:Measurement of Three Axis NC

- Milling Speed:High Speed

- Mold Cavity Technology:EDM Milling

- Driving Motor Type:Reaction Type

- Model NO.:RT-19022004

- Trademark:RootSino

- Origin:Qingdao Shandong

- HS Code:8207300090

- Production Capacity:650 Sets,Year

Description

Basic Info.

Model NO. RT-19022004 Driving Motor Type Reaction Type Mold Cavity Technology EDM Milling Milling Speed High Speed Parts Detection Method Measurement of Three Axis NC Lead Time 20-30 Days Machine Wire EDM Transport Package Wooden Box Specification CE/SGS/RoSH Trademark RootSino Origin Qingdao Shandong HS Code 8207300090 Production Capacity 650 Sets/YearProduct Description

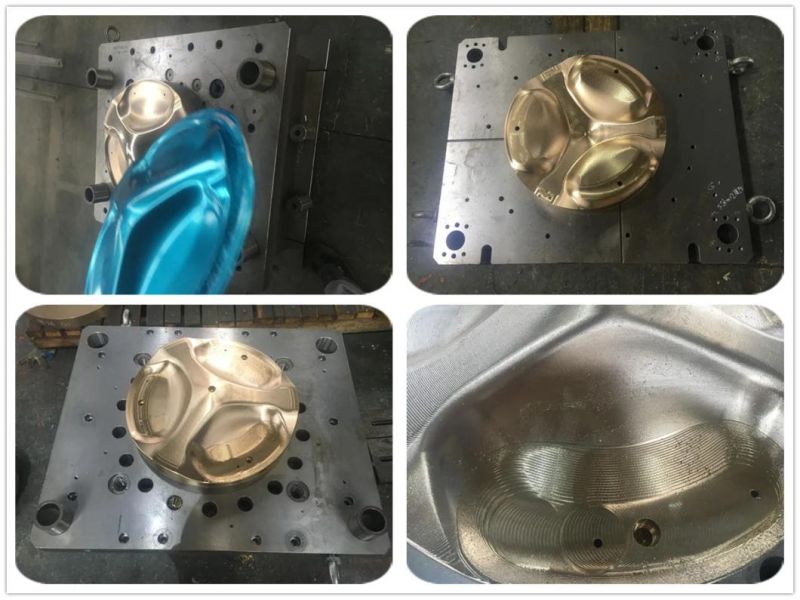

Product pictures

Mold making

Shipment packing

RootChina with over 12 years experience in Progressive die , single-process mold,bending mold,cutting mold,forming mold and relative stamping die production.

Advantage:

1. Specialize in Automotive mold/household mold/daily used product mold about 12 years.

2. High quality & competitive price & professional skills.

3. In house strict quality control.

4. Fast and on time delivery.

5. All mold could be produced automatically

Offered Service:

1. Mold progress report and tooling schedule will be provided weekly.

2. The first testing sample for buyer's inspection and work out improvement requirements will be provided.

3. Mold testing video, 2D part drawing and 3D mold design before shipment will be provided.