Plastic Injection Mold for Thin Wall Container

ZHEJIANG MELEE MOULD CO., LTD.- Plastic Material:HDPE

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Process Combination Type:Single-Process Mode

- Application:Commodity

Base Info

- Specification:SGS

- Transport Package:Wooden Case

- Mould Material:H13

- Cavity:4cav

- Injection Cycle Time:5seconds

- Mould Steel:DIN1.2344pretreat45-55HRC

- Customized:Customized

- Standard:HASCO

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Model NO.:MELEE MOULD-382

- Trademark:MELEEMOULD

- Origin:Huangyan, Taizhou

- HS Code:8480710090

- Production Capacity:350sets ,Year

Description

Basic Info.

Model NO. MELEE MOULD-382 Runner Hot Runner Design Software UG Installation Fixed Standard HASCO Customized Customized Mould Steel DIN1.2344pretreat45-55HRC Injection Cycle Time 5seconds Cavity 4cav Mould Material H13 Transport Package Wooden Case Specification SGS Trademark MELEEMOULD Origin Huangyan, Taizhou HS Code 8480710090 Production Capacity 350sets /YearProduct Description

Detail description of Thin wall injection Mould, IML mould/mold. Lid mould/mold. Thin wall Mould/mold, injection Lid mould, mold, Thinwall Mould. Thinwall Mould maker.Plastic Mould die Makers:

IML LID MOULD material: ABS, PP, PE or as per customer requirement.

IML LID mould cavity: As per customer requirement

New Plastic Products size: Depends on your design.

New Plastic Products material: P20, 718...

New Plastic Products life: 800k shots

New Plastic Products Runner system: Cold runner or hor runner

Plastic Mould die Makers features: Good quality

Injection cycle time: 60seconds

Tooling time: 20days

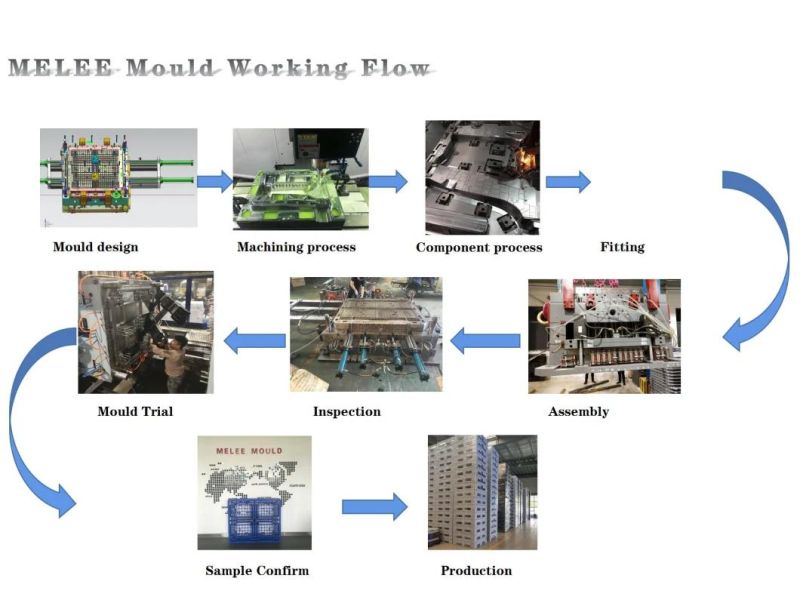

MELEE MOULD Co., Ltd service process for Plastic Mould die Makers

1. Design/sample: Product, mould, etc.

2. Discussion: Mould material, cavity number, price, runner, payment, etc.

3. Order placed: According drawing or your samples.

4. Design mould: We will send mould design to customer for confirmation

5. Mould tooling: We start to make mould after mould design confirmed

6. Mould processing: Send pictures to customer every week for the customer to know the mould processing.

7. Mould shot trial: Send mould shot trial samples to customer to confirm mould quality

8. Delivery: Ship mould after mould quality confirmed.

| Product Name | Thinwall injection Mould |

| Size | ID150x200mm |

| Product description | as per customer requirment |

| IMLMould/Mold cavity | 4cavities |

| IML Mould/Mold size | 550x500x500mm |

| Suitable machine | Around 650T |

| Thin wall Mould/Mold material | P20, 718 |

| Thin wall Mould/Mold life | 800k shots |

| Thin wall Mould/Mold runner system | Cold runner or Hot Runner |

| Ejection system | Ejector BAR |

| Crate Mould/Mold features | Good quality |

| Injection cycle time | 20 seconds |

| Tooling time | 25days |