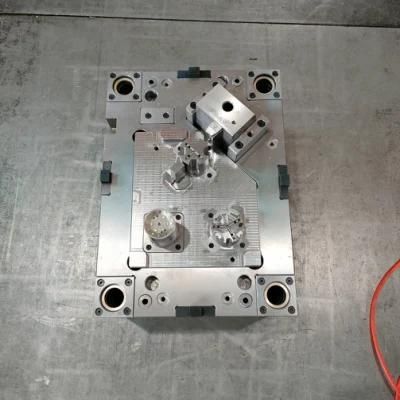

Mold Builder Build Plastic Injection Mold for Plastic Component

Dongguan Howe Precision Mold Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Car, Furniture, Electronic, Hardware

Base Info

- Lead-Time for Batch:15 Work Days

- Lead Time for Mold:4~5 Weeks

- Molding Material:PC,PC,ABS,PC,PMMA,etc

- Sprue Gate:Pin Point Gate, Edge Gate,etc

- Mold Life Time:300, 000~1, 000, 000 Cycles

- Mold Cavity:Single Cavity , Family Molds , Multi Cavity

- Process:CNC Turning, Drilling, Milling, Punching.....

- Name:Plastics Injected Mold

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Fixed

- Design Software:Pro-E

- Runner:Hot Runner

- Model NO.:HW-1125

- Payment Details:T,T, L,C, D,a, D,P, Paypal etc

- Transport Package:Wooden Cases,Air,Sea

- Specification:Custom

- Trademark:HOWE or Custom

- Origin:China

- HS Code:8522901000

- Production Capacity:40sets,Month

Description

Howe Mold was founded in 2010 to produce top class injection molds for the plastics industry. This company has an extensive background in building tools for the electronics, medical, computer, agricultural, automotive, and communications industries. Our customers turn to us to design and build various types of steel and aluminum, single or multi-cavity, molds for injection, structural foam, rim, blow, gas assist and structural web processes. We also design and build aluminum injection molds for limited production runs.Today we serve customers in the computer, automotive, medical, material handling, electronics, and pet industries.

Specializing in three main areas:

1. Manufacture of custom prototype and production injection molds from your part data to a complete mold in just weeks.

2. Rapid turnaround mold repairs, which allow you to get your tools back into production quickly.

3. High quality machining, grinding, CNC machining, EDM and CNC EDM.

•Plastic injection molding parts for architectural parts

•Plastic injection molded auto components

•Injection-molded household utility products

•Plastic molded electronic enclosures

•Plastic molds for medical & dental products

•Injection molding parts for model shops, toys

•Injection plastic parts for new product design & development

•Custom plastic parts for construction

•Plastic injection for Information Technology

•Molded plastic parts for payment system

•Precision plastic parts for Agricultural equipment

•Injection plastic parts for others like cosmetic case

Customer Visiting