China Good Quality UL Plastic Auto Parts Mould for Molding Service

Shenzhen Mingyang Yutong Technology Co., Ltd.- Design Software:Pro-E

- Runner:Cold Runner

- Application:Car, Electronic

- Mould Cavity:Multi Cavity

- Installation:Fixed

- Certification:ISO

Base Info

- Specification:1 trial succeed, export to USA

- Transport Package:Crate Box with Vacuum Packaging for Mold

- Ejector Pin:Dme

- Mold Base:Dme

- Steel:1.2738

- Nozzle Radius:R40

- Location Ring: 125mm:125mm

- Water Connector:Dme

- Customized:Customized

- Standard:DME

- Model NO.:GBM022.7

- Trademark:GBM Mold

- Origin:Shenzhen

- HS Code:84807900

- Production Capacity:200 Sets,Year

Description

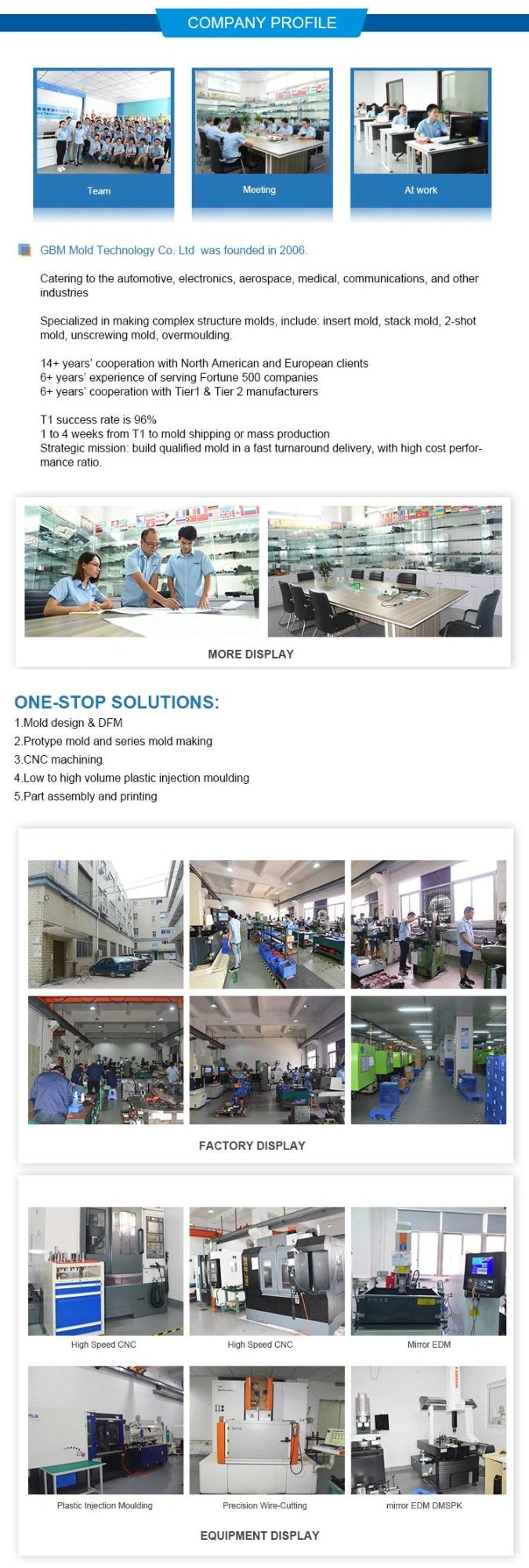

GBM Mold focus on small & medium-sized injection mold with complex construction. We have good experience of making molds as following:

1) Stack mold

such as 3-level stack mold

2) Two-shot mold

for normal 2-component parts and multi-component parts, like 2-component parts with additional metal inserts

3) Unscrewing mold

we are familiar with unscrewing system with hydraulic cylinder, hydraulic motor amd servo motor system.

4) Insert mold

We have rich experience for making normal insert molding mold -One cover and one ejector side, and shuttle mold-One cover and two ejector side, also know as rotational insert mold.

For those parts/components with complex irregular consctruction, GBM Mold team could handle properly for you.

Work with GBM Mold:

1). Professional mold design as the production mould standards

2). Professional mold assembly staff with over 9 years experience

3). 2-shift fast manufacturing with CMM testing for each machining processes

4). Clear project schedule plan and on time delivery

5). Professional project management with efficient communication to make every minutes counts.

GBM Mold Highlight:

9 Inspection Processes

18 Days From Design to Sample

20-Year-Experienced Tooling Engineer

Fortune 500 Company Recommended Mold Supplier

Welcome to contact us for your next custom tooling and molding projects!