Injection Mould for Super Cool Plastic Bike Helmet

Green Vitality Industry Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Commodity, Home Use

Base Info

- Specification:customized

- Transport Package:Plywood Case

- Customized:Customized

- Standard:HASCO

- Certification:ISO

- Installation:Fixed

- Design Software:AutoCAD

- Runner:Cold Runner

- Model NO.:GV-mold-0125

- Trademark:GV

- Origin:Guangdong, China

- HS Code:84807100

- Production Capacity:500sets Per Year

Description

(also other material like PP, PBT, BMC, PMMA, PC+ABS, PP+TD20%, PU, PE, PVC)

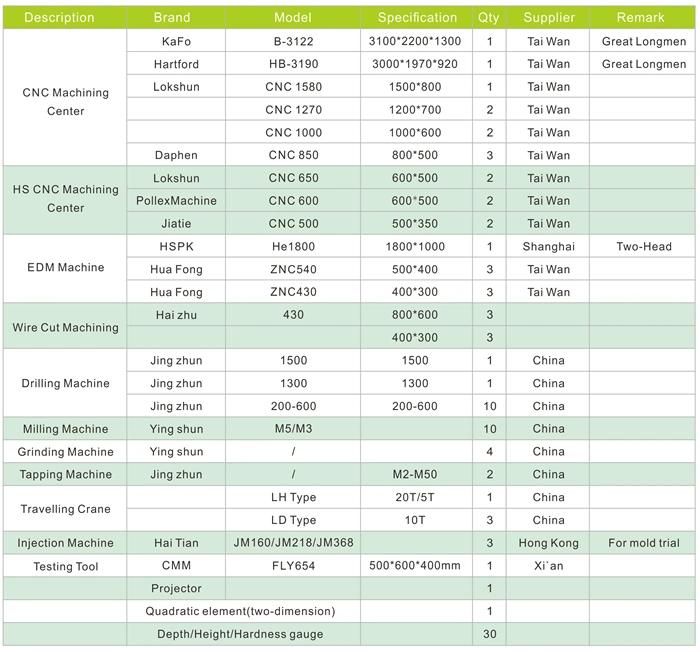

Mold Manufacture Equipment

Factory Photos

About us

Green Vitality has over 25 years of experience making high-quality injection moulds and producing high-quality plastic injection molded components. Our factory has passed ISO 9001:2015, ISO 14000 and TS16949 are also in our agenda. We also offer assembly and packaging services. This capacity ensures we can fulfill multiple high-volume orders quickly.

Our capabilities include:

- Prototyping

- Multi-cavity Mold

- Two-Shot Mold

- Insert molding

- Overmolding

- Mold maintenance and repair

- High-volume order production

- Finishing services (Ultrasonic Welding, Sonic Welding, Silk Screening,pad printing, Painting, in-mold decorating, labeling)

- Product assembly

Our advantage and service:

1. We are a mold manufacturer,so we quote the first-hand quotation, no middleman.

2.We have the self-management import and export license.

3. We have been in the mold industry for 25 years, all of our sales staff have more than 5 years of mold industry experience.

4. All of our molds quality based on Europe standard and American standard.

5. Prompt afer-service. We provide lifetime after-sale technical support.

6.One-stop service and No MOQ limited.

Your OEM and ODM model are welcomed.

* Customize drawings or design or idea can be realized.

* Design the drawings according to your drawing, sketch or samples.

* Small prouction orders are also acceptable.

* High quality and short lead time, professinal and cost-saving mold solution supplier.

We manufacture, assemble, pack, store and distribute

Once your semi-finished products have been manufactured, we are able to assemble your items, and also complete the production cycle through to final packaging, ready for distribution to anywhere in theworld.

We have the capability to add additional components which we either produce or source from worldwide partners, assemble and package your products to complete the manufacture of your items.

This is an one stop service which is hard to be beat.

We hope you to be able to concentrate on what you are good at, and leave the rest to us!

Highlights

General assembly, by individuals and on production lines by teams.

Hotplate welding.

Heat stacking of inserts.

Ultrasonic welding assembly of plastic components.

Manual assembly of components to build up subassemblies or finished assemblies,

Packing.

"Wonderful Design + Professional Mold maker = Perfect Product"

You will enjoy our good service and cost-effective solutions from design to delivery.

FAQ

Below is a list of answers to most frequently asked questions about Green Vitality.

Q:Which kinds of equipment in your workshop?

A:Our company has 14 sets of computer CNC machining centers, high-speed carving CNC 9 units, large gantry CNC (military grade) 2 sets of machining centers, EDM machine 6, currently the world's most advanced double spark machine, precision grinding six , three large water mill, lathe, milling machine 10, radial drill two sets, desktop drilling machine, deep hole drilling, 3 sets of 8 Fast thread cutting and other processing equipment, as well as ancillary products measured using three measurements yuan, two MEs, projection measuring instrument, hardness tester and other equipment

Q:What kind of payment conditions do you accept?

A:Usually we accept standard payment conditions - that is: 40% of total prices down payment, 40% on mould first trial and 20% on mould delivery. Particularly, in case of bigger contracts. The preferable forms of payment are wire transfer and letters of credit. We often use a combination of those.

Q:Can you provide the steel certificate and heat-treatment certificate?

A:Yes, we can. The steel supplier and heat-treatment factory can provide the certificates.

Q:How long is the lead-time for a mould?

A:It all depends on the mould's size and complexity. Usually, the lead-time is about 25-65 days.