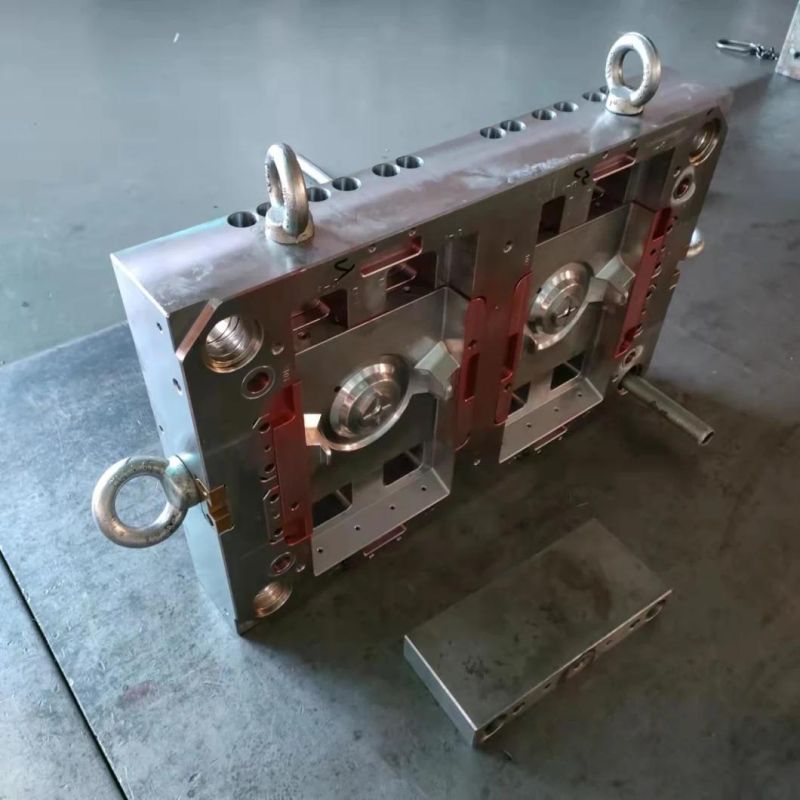

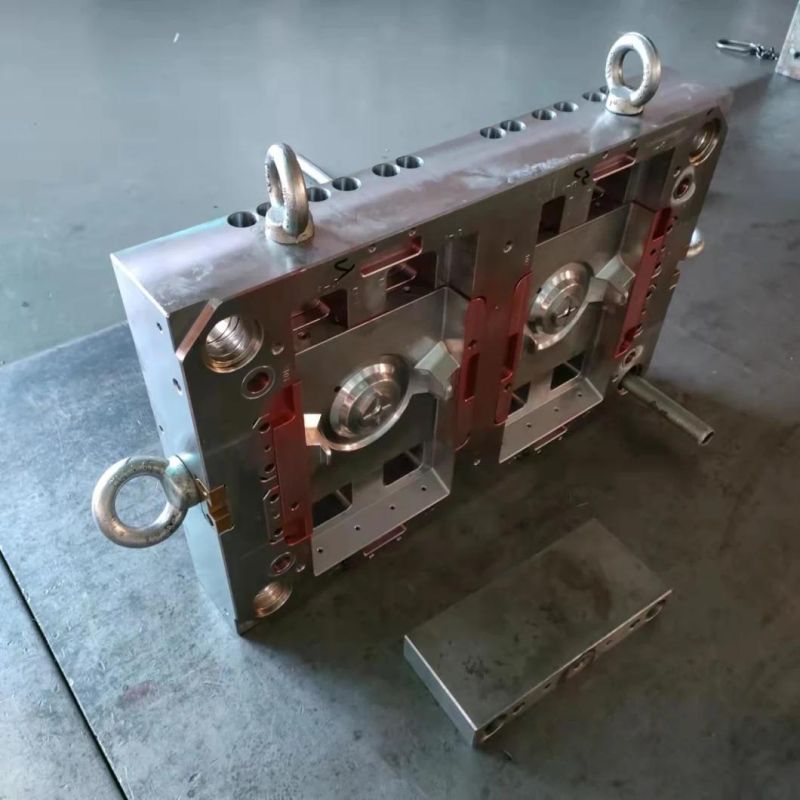

Custom Making Plastic Injection Mould for Nylon Plastic Enclosures

Dongguan Howe Precision Mold Co., Ltd.- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Polishing

Base Info

- Lead-Time for Production:1~2 Weeks

- Lead Time to T1 Sample:4~5 Weeks

- Mold Type:Insert Mold, Over Mold, Shuttle Mold

- Hot Runner:Moldmaster, Incoe, Yudo, Heitec, Gunther, etc

- Finish:Pitting The Word, Mirror Finish, Matte Surface

- Process:Injection Molding

- Mould Material:S136,Nak80,P20,718h,etc

- Mould Life:300,000-1,000,000times

- Product Name:Plastic Injection Toolings for Baskets

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Fixed

- Design Software:Pro-E

- Runner:Cold Runner

- Model NO.:HW-1116

- Package:Wooden Case Package

- Transport Package:Wood Box and Wood Pallet

- Specification:According to your drawing

- Trademark:Custom

- Origin:Guangdong, China

- HS Code:8480719090

- Production Capacity:40sets,Month

Description

PLASTIC INJECTION MOULD BASIC DESCRIPTIONInjection System Hot /Cold Runner Inserts(cavity and core) H13, 1.2344, 1.2738, 1.2083, 1.2311, NAK80 or the material you required. Mold Cavity 1*1,1+1,1*2,1+1+1,etc Gate type Side gate,Sub gate,Pin point gate,Edge gate etc Ejector System Stripper plate,Lifter,Push bar,Ejection pin etc Steel Standard FINKL,Assab,DAIDO,LKM,Buderus Cooling Baffles/Sprin Piple/3D printing water line Lead time of first samples Around 4~7weeks Standard Parts/Cylinders DME/HASCO/PROGRESSIVE/MISUMI/Parker/HP/Merkle Design Capability DFM,Mould flow analysis,Product optimization, Full 2D & 3D mould design,Reverse engineering,Collaborative design with customer's idea Documents / Reports Provided Fully drawing,Weekly Processing Report, Steel Dimension report, Processing Report,Sample Dimension Report.

Company Profile

Howe Precision Mold Co. is a qualified engineering and manufacturing company that designs and makes production tools of high-quality injection mold and die-cast mold for plastics molding and metal casting in wide ranges of automotive, household appliances, consumer goods, etc., with an engineering team over 11 average years of experience. Established in Dongguan City China, by the general manager Mr. Shawn Lee with the technical backgrounds.

Work Shop

Company Profile

Howe Precision Mold Co. is a qualified engineering and manufacturing company that designs and makes production tools of high-quality injection mold and die-cast mold for plastics molding and metal casting in wide ranges of automotive, household appliances, consumer goods, etc., with an engineering team over 11 average years of experience. Established in Dongguan City China, by the general manager Mr. Shawn Lee with the technical backgrounds.

Work Shop