Plastic Injection Molding Mould Professional Manufacturer Customized Tooling Mold Making

Dongguan Cheng Kang Mould & Plastic Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:Customized

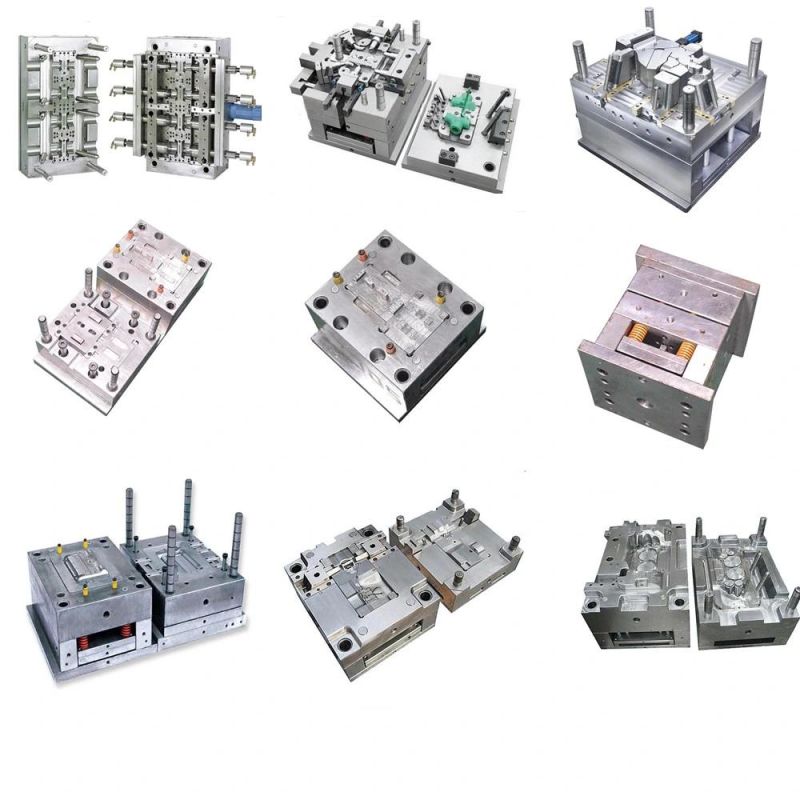

- Mould Cavity:Single Cavity and Multi Cavity Available

- Shaping Mode:Plastic Molding Die

- Surface Finish Process:Polishing

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Base Info

- Transport Package:Wooden Box,Carton

- OEM & ODM:Acceptable

- Tolerance:±0.02mm

- Mould Base:Lkm, Hasco, Dme

- Lead Time for Tooling:30-45 Days

- Customized:Customized

- Standard:Lkm

- Certification:ISO

- Installation:Fixed

- Design Software:Chinese Software

- Runner:Hot&Cold Runner

- Model NO.:CK0038

- Specification:Customized

- Trademark:ChengKang

- Origin:Dongguan China

- Production Capacity:50 Set,Month

Description

Basic Info.

Model NO. CK0038 Runner Hot&Cold Runner Design Software Chinese Software Installation Fixed Certification ISO Standard Lkm Customized Customized Lead Time for Tooling 30-45 Days Mould Base Lkm, Hasco, Dme Tolerance ±0.02mm OEM & ODM Acceptable Transport Package Wooden Box/Carton Specification Customized Trademark ChengKang Origin Dongguan China Production Capacity 50 Set/MonthProduct Description

Basic Product Information:| Item | Custom Plastic Injection Molding |

| Application | Automotive industry, electronic and electrical appliances, medical industry, fiber-optical and transmission industry and customized components, concerning connector molding parts, auto parts, medical parts and other tooling, etc. |

| Customized | We accept customized product.You can provide us the product or 3D drawing. |

| Mould Material | P20 , 718, 2344 ,H13,8402,8407, SKD 61, NAK80,2344, 2343,S136,etc |

| Products Material | PA,PA6/6+GF,ABS,POM,PC,PP,PET,TPE,PVC,HDPE etc |

| Cavity | Single-cavity ,Multi-cavity |

| Runner system | Hot runner , Cold runner |

| Mould life time | 300,000~+1,000,000 shots |

| Packaging | In strong wooden pallets to avoid any damages during the long transportation |

| Transportation | Air cargo, Sea shipping, or as you request |

| Lead Time | 30-50 workdays based on the different products |

| OEM/ODM | Acceptable |

| Surface Treatment | polishing,sandy finishing,electroplating,etc. |

| Payment term | T/T |

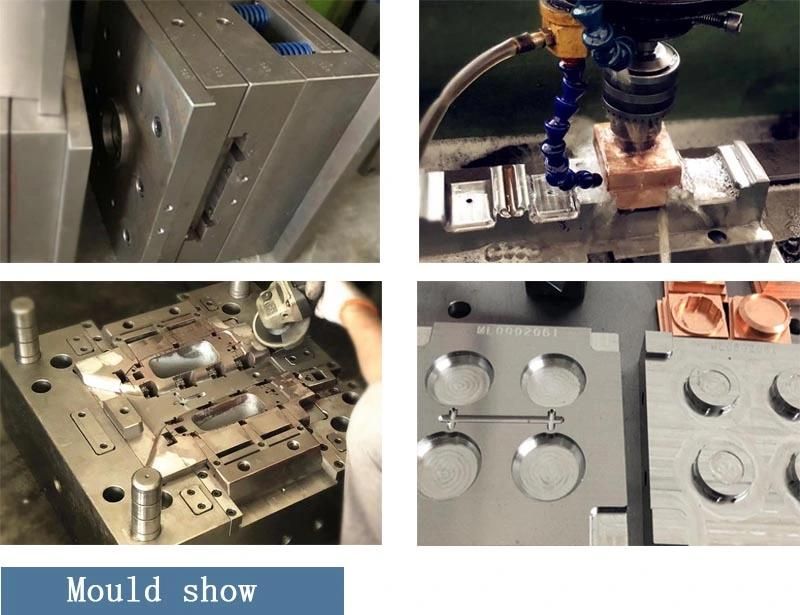

Mould Machine: 2 Mould Machines,4 EDM Machines,1 High Speed CNC Carving and Milling Machine,

7 Milling Machines and 3 Grinding Machines

Plastic Injection Machine:10 Plastic injection molding machine,6 Precision injection molding machine

2) Professional Working Team:

Mould Desin Department: We have a R&D Team including more than 5 engineers with excellent design

abilities over 20years.

Mould Production Department: Over 10 experiened workmen in charge of our factory's mould production.

Plastic Injection Production Department:1 supervisor,2 workshop foreman,2 QC,1 material purchaser and group of worker

to produce and self-check plastic injection products.

Office: Over 10 experiened employees in charge of our company work affair.each one is

responsible for specialized job.

3) Supply "one-stop" service

4) All of our operations are strictly compliant with ISO 9001: 2015 guidelines.

5) Strict quality control systems

6) Short lead time.

7) Perfect package for export.

8) Superior after-sales service

In August 2006, the company passed the ISO9001 international management system certification

In June 2007, Hong Kong company hongrun plastic hardware products co., LTD was set up

FAQ

FAQQ: What is your business scope?

A: Our company mainly produces plastic mould and injection plastic parts

Q: What industries do your products mainly cover?

A: In the past 20 years, we have developed and manufactured moulds including electronic products, furniture, lighting products, daily necessities, medical equipment, engineering equipment, etc.In recent years, the intelligent technology industry has been on the rise, at the same time, we have received a lot of product demand for intelligent technology and mold development.

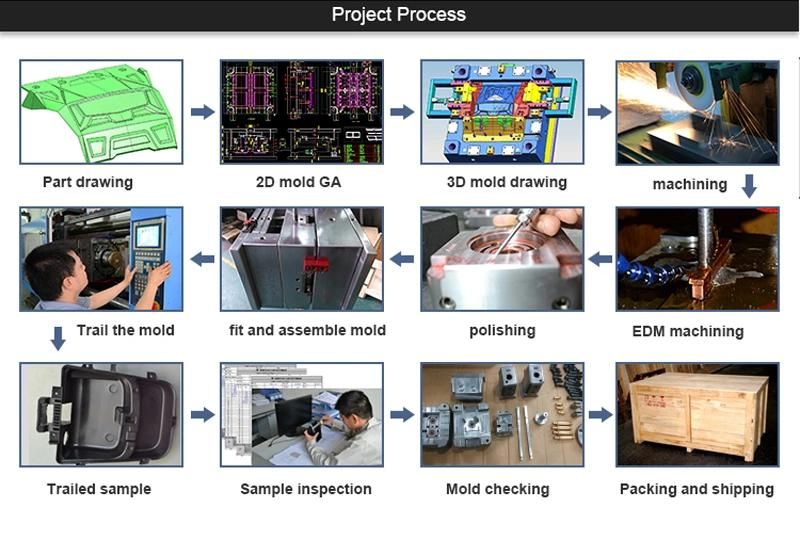

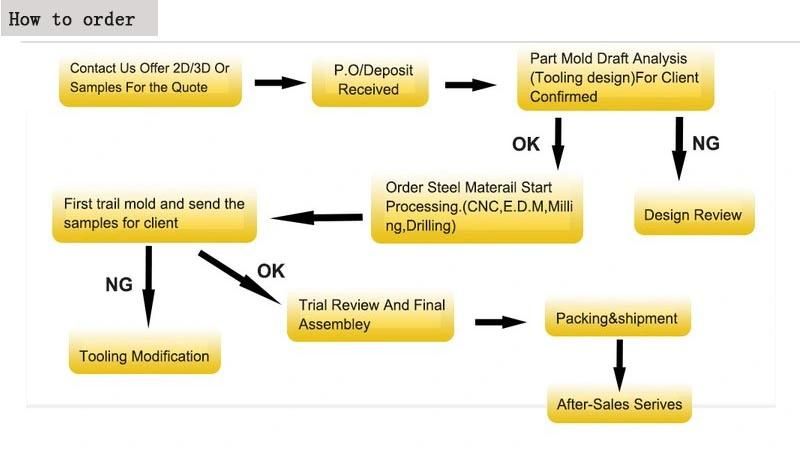

Q: What is the processing for Mold inquiry and quote?

A: If you are going to make an inquiry of mold, please give us the basic information with 3D drawing or 2D drawing or any other detail information(material, part weight, qty, etc), and we will give you answer within 24hours .

Q: Which countries do you often work with?

A: Our customer groups include: USA, Germany, Italy, Portugal and China ETC

Q:What successful programs have you had?

A:We have provided die manufacturing work and injection molding work for many world famous enterprises such as

Electrolux,Bondi, Nokia, Chase and Bentley, and have achieved great success cooperation with them.

Q:What are the main ways of transporting the products?

A: We have a number of cooperation international logistics, DHL, Fedex, SF Express, etc., before the goods delivered we will strict packaging products to ensure the goods would reach the destination safely.

Welcome to order our Custom Plastic Injection Molding!

We also hope you can find quality suppliers in China