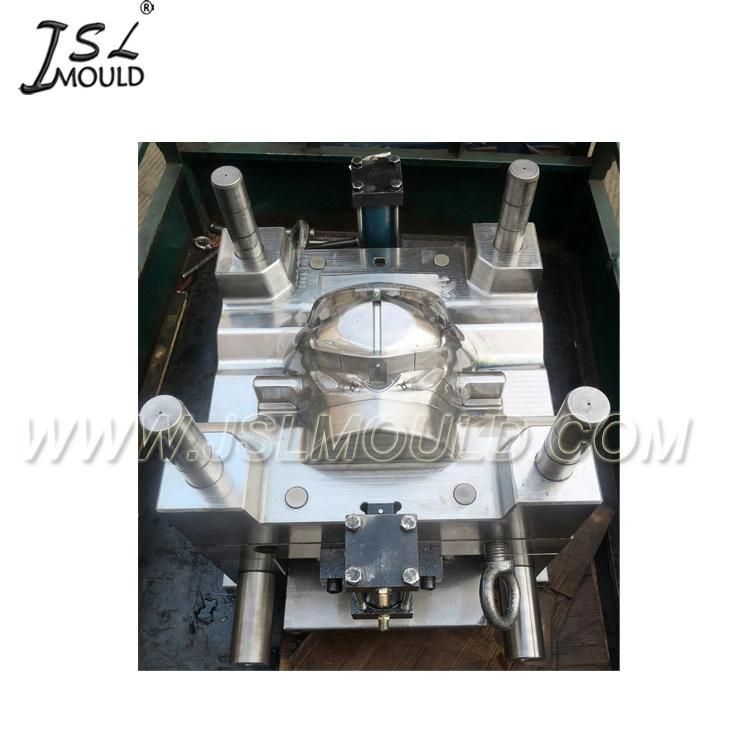

Motorcycle Plastic Body Fairing Mould

Taizhou City Huangyan Beiwei Mould Industry Co., Ltd.- Plastic Material:ABS

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Warranty:1 Year

- Process Combination Type:Single-Process Mode

Base Info

- Mould Design Software:Ug,Proe,CAD,Catia,Solidworks

- Mould Life:More Than 500k Shots

- Mould Steel:718 (34-38HRC)

- Mould Name:Plastic Injection Automotive Spare Part Mould

- After-sales Service:3year

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Fixed

- Design Software:UG

- Runner:Cold Runner

- Application:Car

- Model NO.:JSL-F15884

- Mould Delivery Time:45 Days

- Transport Package:Wooden Crate

- Specification:Dme

- Trademark:JSLMOULD

- Origin:China

- HS Code:8480719090

- Production Capacity:300sets,Year

Description

Basic Info.

Model NO. JSL-F15884 Application Car Runner Cold Runner Design Software UG Installation Fixed Certification ISO Standard DME Customized Customized After-sales Service 3year Mould Name Plastic Injection Automotive Spare Part Mould Mould Steel 718 (34-38HRC) Mould Life More Than 500k Shots Mould Design Software Ug,Proe,CAD,Catia,Solidworks Mould Delivery Time 45 Days Transport Package Wooden Crate Specification Dme Trademark JSLMOULD Origin China HS Code 8480719090 Production Capacity 300sets/YearProduct Description

Product Name motorcycle plastic body fairing mouldProduct material ABS

Core&Cavity Steel 2738

Steel hardness: HRC35-38

Mould Standard DME

Cavity Number SINGLE

Injection System SIDE GATE

Ejector System EJECTOR PIN

Cycle Time 35S

Tooling lead time 50DAYS

Mould life 1, 000, 000SHOTS

Quality assurance ISO9001

Our Advantage 1. High quality

2. Reasonable price

3. On time delivery

4. Good After-sale service

5. Strict quality control

6. All the mould are automotic.

Offer you In-time response on letters, telephone calls or fax

In-time supply the quotation and mould designs

In-time communication on the technical points

In-time sending pictures for the mould machining progress and mould finishing schedule

In-time mould test and sample delivery

In-time mould delivery.

For more information please contact us.

Provide mould core & cavity steel certificate

Provide mould trial video and good after-service

1. Long life

2. Short delivery time

3. With best machining

4. Good after-service

JSL Mould Quality Control

For the Q/C of mould, there are 3 steps:

1. Mould Material Q/C

- Mould Steel Checking(Hardness, flaw detection)

- Mould Standard Spare Parts Checking(hardness, size, flaw checking)

2. Mould Making Process Q/C

- design checking (part design, mould design, mould engineering drawing)

- checking each part of mould's size after machining, according to 2D drawing

- mould testing(check mould running condition)

3. Check with customer's requirement again before mould shipping