Plastic Wash Basin Injection Mould Laundry Basin Mold

TAIZHOU U-KNOW MOULD CO., LTD.- Process Combination Type:Single-Process Mode

- Plastic Material:PP

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Household Appliances, Furniture, Commodity, Home Use

Base Info

- Specification:45#, P20, H13, 718, 2738, NAK80, S136etc.

- Transport Package:Wooden Case

- Customized:Customized

- Standard:HASCO

- Certification:ISO

- Installation:Fixed

- Design Software:UG

- Runner:Hot,Cold Runner

- Trademark:UK

- Origin:China

- HS Code:8480719090

- Production Capacity:500 Sets,Year

Description

Basic Info.

Runner Hot/Cold Runner Design Software UG Installation Fixed Certification ISO Standard HASCO Customized Customized Transport Package Wooden Case Specification 45#, P20, H13, 718, 2738, NAK80, S136etc. Trademark UK Origin China HS Code 8480719090 Production Capacity 500 Sets/YearProduct Description

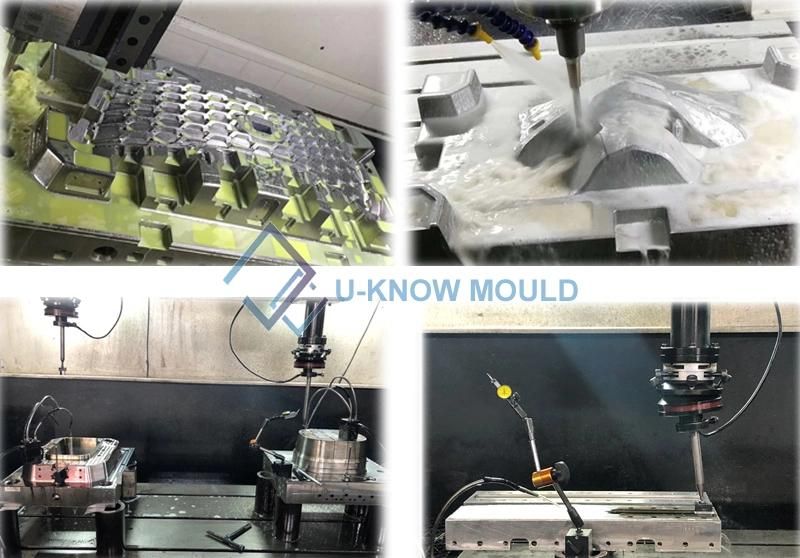

Product DescriptionIn our market, about 80% of plastic basins use cold runner systems - large direct gates. When producing from injection molding machines, it is necessary to cut the water injection channels (waste) by hand, requiring a lot of time and labeling.But if you use hot runner system, it is more expensive than cold runner system,which is no cost-efficient.U-KNOW MOULD could help you design and manufacture your plastic basin mould with cold runner-insulated gate which does not have waste material.By using such equipment ,your money and time will large be reduced.

Our Advantages

1. Workable price with excellent quality

2. R&D center to meet your program requirements

3. Diversified rich experience skilled engineers and workers

4. Professional pre-sale service and on time after-sales

5. More than 20 years experience in this filed

6. OEM & ODM available

Our Promise

1.Mould Making Process Q/C

a) mould testing (check mould working,sample)

b design checking ( part design,mould design,mould engineering drawing)

c) mould size checking (according to drawing)

2.Mould Material Q/C

a) mould spare parts checking (hardness,size)

b) mould steel checking (hardness,flaw detection)

About Us

After-sale Services

1).During Mould Manufacturing, every week or everyday (if customer want ),we will offer update mould picture or video to customer .

2).When mould test, we will send video and photos to customers.

3).Before Mould delivery, packing video and photos(wooden case, painted with anti-rust) will be both offered for customers.

4).If mould stay in our factory to production ,life warranty.

One year warranty after mould exported. During warranty, all maintenance are free of charge.

Packaging & Shipping

- Mould surface of core and cavity will be covered by antirust

- The mould surface will be covered by butter

- The mould will be packed by plastic membrane

- The mould will be put into wooden case

- Some other spare parts will be put into the wooden case together with mould, there are lifting bolt, water nozzle, water hose. Ejector-pin etc.