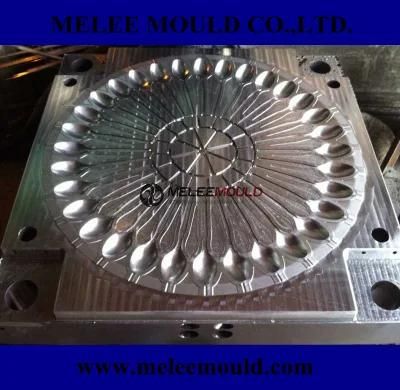

Plastic Injection Series Spoon Mould

ZHEJIANG MELEE MOULD CO., LTD.- Plastic Material:ABS

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Process Combination Type:Single-Process Mode

- Application:Commodity

Base Info

- Trademark:MELEEMOULD

- Specification:SGS

- Transport Package:Wooden Case

- Mould Material:P20,718...

- Commodity Mould:Spoon and Colander

- Shape:as Customer′s Request

- Size:350X200X180mm

- Customized:Customized

- Standard:HASCO

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Model NO.:MELEE MOULD-723

- Origin:Huangyan, Taizhou

- HS Code:8480710090

- Production Capacity:350sets ,Year

Description

Basic Info.

Model NO. MELEE MOULD-723 Runner Hot Runner Design Software UG Installation Fixed Standard HASCO Customized Customized Size 350X200X180mm Shape as Customer′s Request Commodity Mould Spoon and Colander Mould Material P20,718... Transport Package Wooden Case Specification SGS Trademark MELEEMOULD Origin Huangyan, Taizhou HS Code 8480710090 Production Capacity 350sets /YearProduct Description

Meeting your requirement as our standard,Punctuality and Good quality is our standard.

With the least money to achieve the best effect.

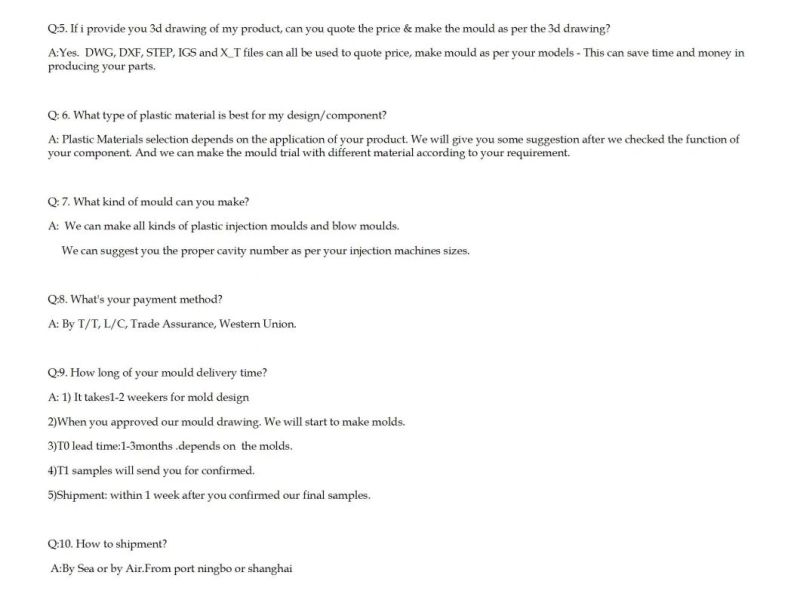

Detail description of Plastic commodity mould/mold. spoon Mould/mold,

Used Basket Mold, Commodity Mold, daily use mould

Product Name: Basket mould/mold

Plastic commodity mould/mold material: ABS, PP, PE or as per customer requirement.

Plastic commodity mould/mold cavity: As per customer requirement

Plastic commodity mould/mold size: Depends on your design.

Plastic commodity mould/mold material: P20, 718...

Plastic commodity mould/mold life: 800k shots

Plastic commodity mould/mold Runner system: Cold runner or hor runner

Plastic commodity mould/mold features: Good quality

Injection cycle time: 60seconds

Tooling time: 20days

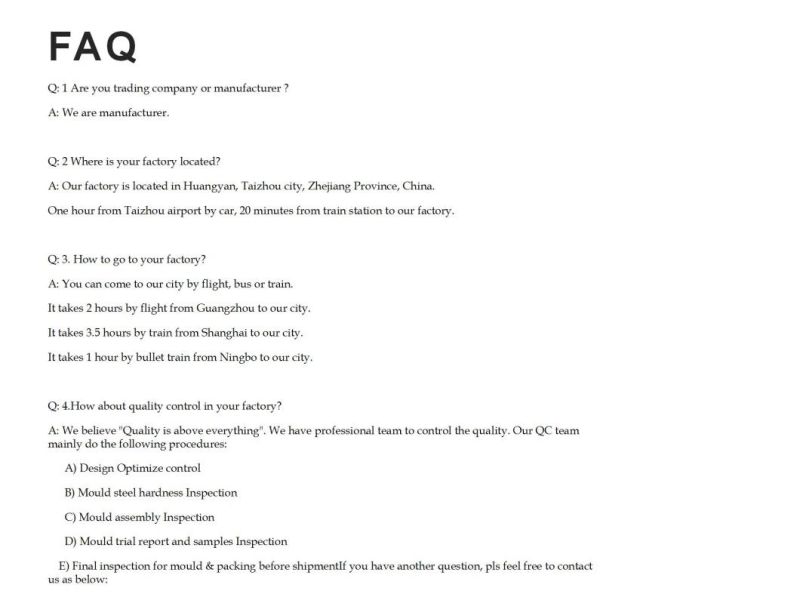

MELEE MOULD Co., Ltd service process for Plastic commodity mould/mold

1. Design/sample: Product, mould, etc.

2. Discussion: Mould material, cavity number, price, runner, payment, etc.

3. Order placed: According drawing or your samples.

4. Design mould: We will send mould design to customer for confirmation

5. Mould tooling: We start to make mould after mould design confirmed

6. Mould processing: Send pictures to customer every week for the customer to know the mould processing.

7. Mould shot trial: Send mould shot trial samples to customer to confirm mould quality

8. Delivery: Ship mould after mould quality confirmed.

| Product Name | commodity mould/mold |

| Size | 800x450x500mm |

| Product description | as per customer requirment |

| Plastic basket mould/mold cavity | 1cavity |

| Plastic basket mould/mold size | 1050x650x700mm |

| Suitable machine | Around 650T |

| Plastic basket mould/mold material | P20, 718 |

| Plastic basket mould/mold life | 800k shots |

| Plastic basket mould/mold system | Cold runner or Hot Runner |

| Ejection system | Ejector BAR |

| Plastic basket mould/mold features | Good quality |

| Injection cycle time | 60 seconds |

| Tooling time | 20days |