Custom Automotive Plastic Injection Molding Car Plastic Parts ABS PA66 Injection Mold

Shenzhen Mingyang Yutong Technology Co., Ltd.- Plastic Material:PP

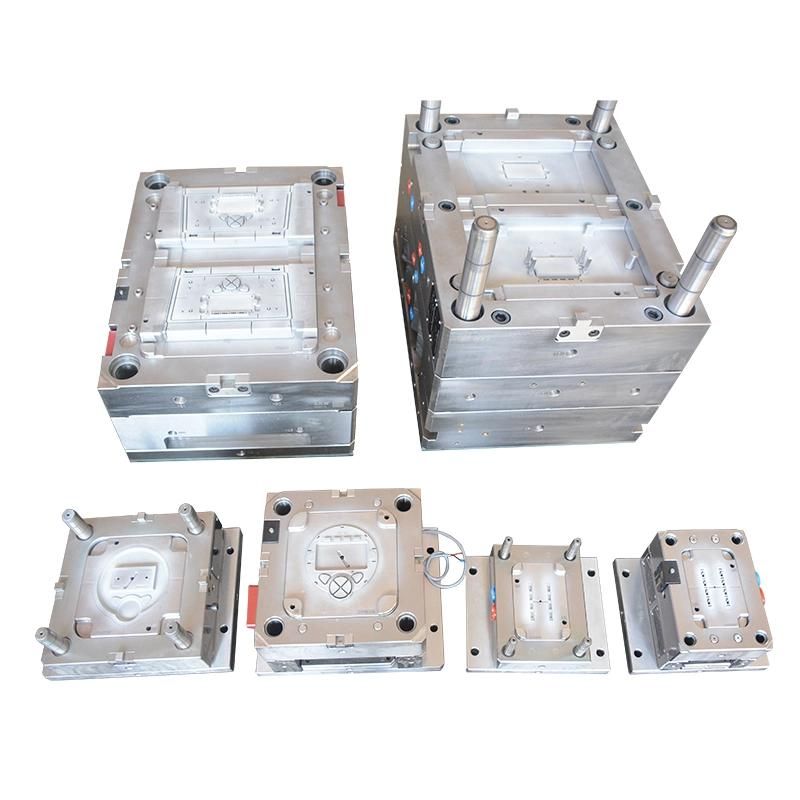

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Warranty:2 Years

- Process Combination Type:Single-Process Mode

Base Info

- Ejector Pin:Dme

- Steel:1.2738

- Mold Base:Dme

- Nozzle Radius:R40

- Location Ring:125mm

- Water Connector:Dme

- Customized:Customized

- Standard:HASCO

- Certification:ISO, SGS, China Hi-Tech Enterprise Certificate

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Model NO.:GBM Mold

- Transport Package:Crate Box with Vacuum Packaging for Mold

- Specification:Multi-cavity stack mould

- Trademark:GBM

- Origin:Shenzhen

- HS Code:84807900

- Production Capacity:200 Sets,Year

Description

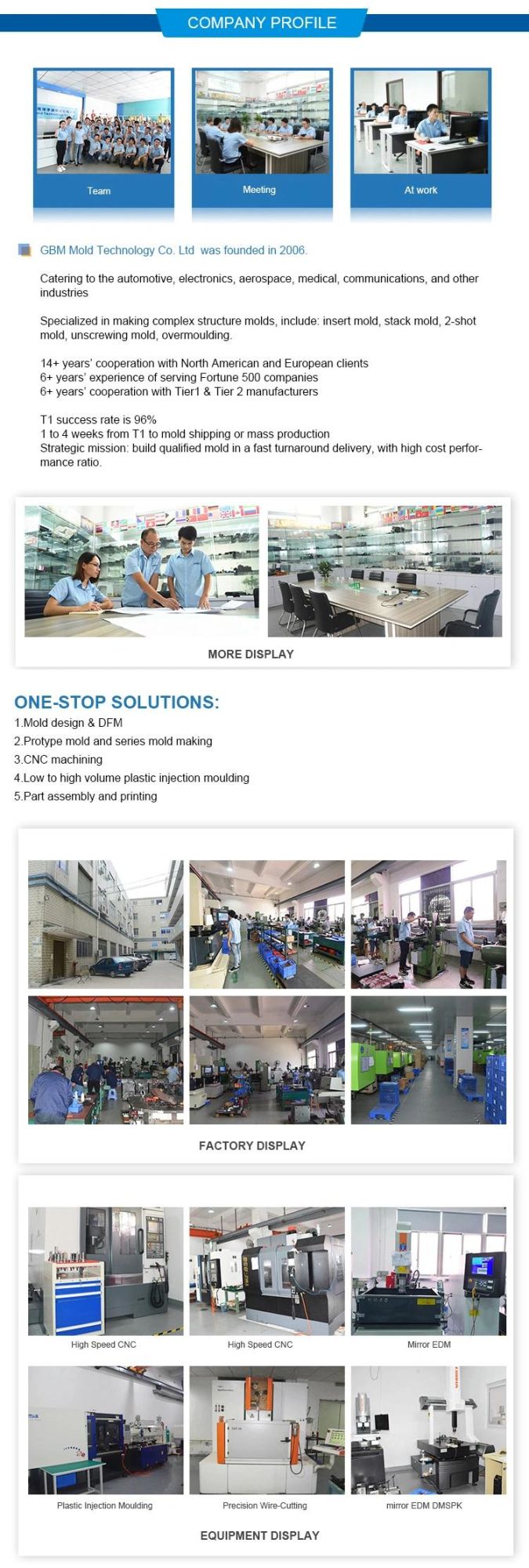

Every project in GBM has a story behind it

1) German customer, old customer but 1st time for them to make stack mold.

2) Urgent project, fast delivery required.

3) 1 week finished mold design, familiar with customer's tooling requirements.

4) 1st mold trial succeed. Customer saw the trial by video conference.

5) T1 samples get the final approval.From design to delivery, overall project lead time 9 weeks.

6) While shipping the mold, we made an operation guide PPT for customer, to help make their mold trial and production run easier.

The mold is keep running well at customer's plant.

If you are looking for a tool maker to handle your projects smoothly, to help you achieve an early good result, contact us now!

GBM Mold focus on small & medium-sized injection mold with complex construction. We have good experience of making molds as following:

1) Stack mold

such as 3-level stack mold

2) Two-shot mold

for normal 2-component parts and multi-component parts, like 2-component parts with additional metal inserts

3) Unscrewing mold

we are familiar with unscrewing system with hydraulic cylinder and unscrewing system with hydraulic motor

4) Insert mold

We have rich experience for making normal insert molding mold -One cover and one ejector side, and shuttle mold-One cover and two ejector side, also know as rotational insert mold.

For those parts/components with complex irregular consctruction, GBM Mold team could handle properly for you.

If time allows welcome to schedule a visit to our factory in Shajing town of Shenzhen city. I would love to hear from you.

Specification:

Mold base: LKM mold base with equivalent Hasco

standard guide pin & bushing

Mold material: 1.2343

Cavities: 2+2

Injection type: hot runner

OEM production accepted

Mold life: 1,000,000 shots

Plastic materials: PP

Delivery lead time:

Mold: 40 days

Plastic parts: production to be arranged after sample approval within 7 days

Packing:

Injection mold: by sea freight, crate box with vacuum packaging for mold

By air freight, crate box, with cling film packaging

Plastic parts: PE bags, carton yard for each layer, good-quality packaging box