Custom Casting Molds for Injection

Qingdao Seger Industrial Co., Ltd.- Using Hardness:HRC30~45

- Surface Treatment:Coat-Plating

- Demoulding:Slide

- Material:Iron

- Application:Hardware

- Average Wall Thickness:>3mm

Base Info

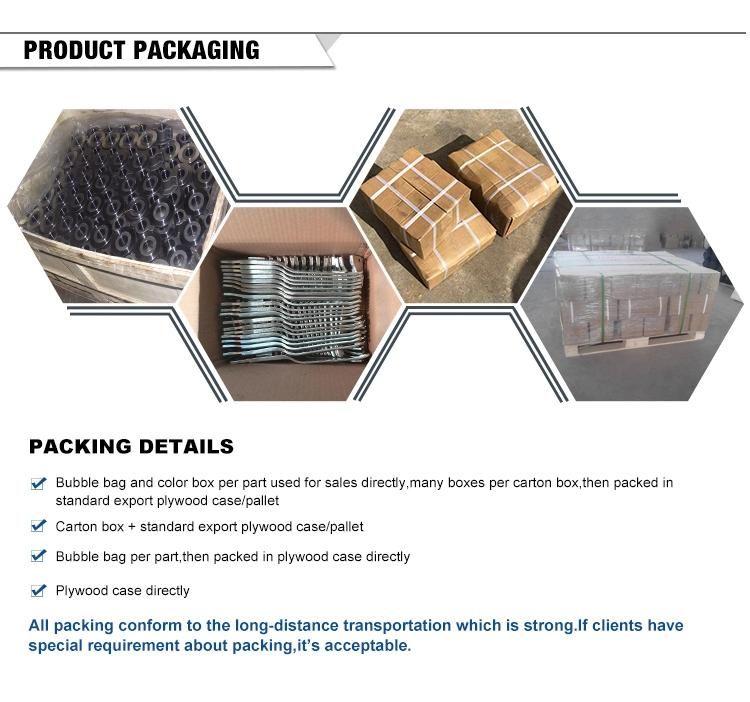

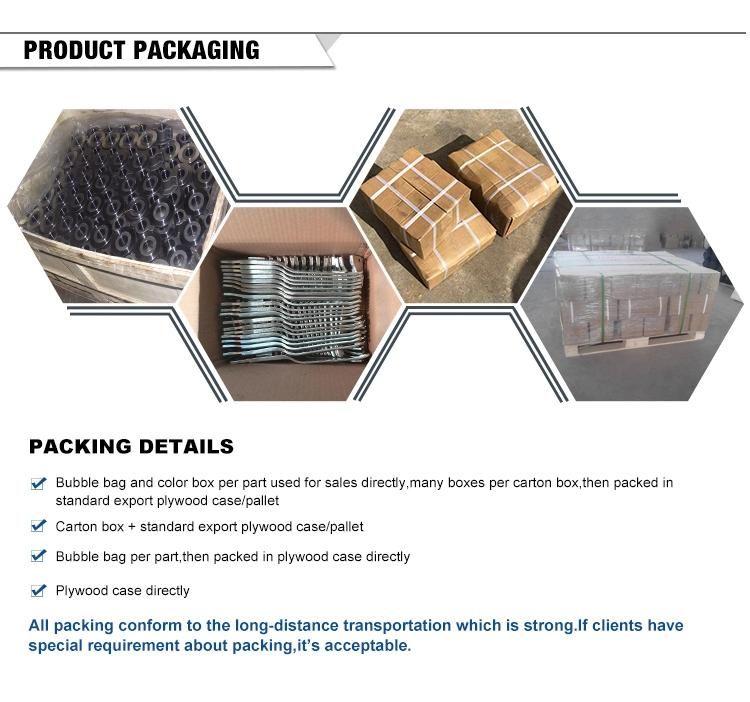

- Transport Package:Normal Export Carton Box+Wooden Case,Pallet

- Technicial:Casting, Forging, Machining..

- MOQ:200PCS

- Condition:New

- OEM Service:Yes

- Customized:Customized

- Mould Life:<500,000 shots

- Model NO.:SE-78

- Specification:ISO9001: 2000

- Trademark:Seger

- Origin:Shandong, China

- HS Code:73251010

- Production Capacity:50, 000 PCS Per Month

Description

InspectionFoundry in-house Third Party inspection available upon customers requirements

Related Product Show

Glad to tell you we can manufacture all kind of iron casting with grey iron, ductile iron or wrought iron by drawing and samples.

If you have any inquiry of custom iron casting, please feel free to contact us.

Your inquiry of iron casting, will be highly appreciated.

2. Strict Quality Control

We can supply products with the following test reports:

1) Chemical composition report

2) Tensile strength report

3) Brinell hardness report

4) Metallographic structure report

5) Key dimension checking report

6) Full dimension report

7) Third part test report

We will design each speical checking tooling control key dimension during production to ensure each key dimension under control.

Packing:

A>Seger packing: Carton box+wooden case/pallet/iron cage

B>As pre client's special requirement

Our Service:

*A "bespoke" service to make castings and forgings to customers specific requirements with drawings, samples

*Market-oriented, different grades of products geared to the needs of different customers

*Advance equipment, professional technology and serious inspection procedure to ensure good quality

*In-time delivery will always satisfy customers" needs

*Best after-sale service all the time for a long trade cooperation term

FAQ:

Q1: What's the lead time?

A1: In general, the lead time is about 30~40 days for opening new moulds and mass production.

Q2: What file formats does Seger accept for drawings:

A2: The company ca accept a range of formats for drawings, but the main ones are detailed below: 2-D PDF AND TIFF 3-D STL, IGES, STEP, Solidworks, etc

Q3: Is it possible to visit seger to view it's manufacturing process?

A3: We are extremely proud of our facility and existing customers to visit our company. We think you will be impressed by us, as well as the warm welcome from our friendly, experienced team.

clients comment

For more details,pls feel free to contact us.

Related Product Show

Glad to tell you we can manufacture all kind of iron casting with grey iron, ductile iron or wrought iron by drawing and samples.

If you have any inquiry of custom iron casting, please feel free to contact us.

Your inquiry of iron casting, will be highly appreciated.

2. Strict Quality Control

We can supply products with the following test reports:

1) Chemical composition report

2) Tensile strength report

3) Brinell hardness report

4) Metallographic structure report

5) Key dimension checking report

6) Full dimension report

7) Third part test report

We will design each speical checking tooling control key dimension during production to ensure each key dimension under control.

Packing:

A>Seger packing: Carton box+wooden case/pallet/iron cage

B>As pre client's special requirement

Our Service:

*A "bespoke" service to make castings and forgings to customers specific requirements with drawings, samples

*Market-oriented, different grades of products geared to the needs of different customers

*Advance equipment, professional technology and serious inspection procedure to ensure good quality

*In-time delivery will always satisfy customers" needs

*Best after-sale service all the time for a long trade cooperation term

FAQ:

Q1: What's the lead time?

A1: In general, the lead time is about 30~40 days for opening new moulds and mass production.

Q2: What file formats does Seger accept for drawings:

A2: The company ca accept a range of formats for drawings, but the main ones are detailed below: 2-D PDF AND TIFF 3-D STL, IGES, STEP, Solidworks, etc

Q3: Is it possible to visit seger to view it's manufacturing process?

A3: We are extremely proud of our facility and existing customers to visit our company. We think you will be impressed by us, as well as the warm welcome from our friendly, experienced team.

clients comment

For more details,pls feel free to contact us.