Power Press 2000t Production Line with Tools and Transfer System

Zhejiang Jinaolan Machine Tool Co., Ltd.- Material:Cr12MOV

- Processing Method:Punching and Shearing Mould

- Application:Household Appliances, Electronic, Hardware, Car, Commodity, Home Use

- Warranty:2

- Technics:Cutting Die

- Process Combination:Progressive Die

Base Info

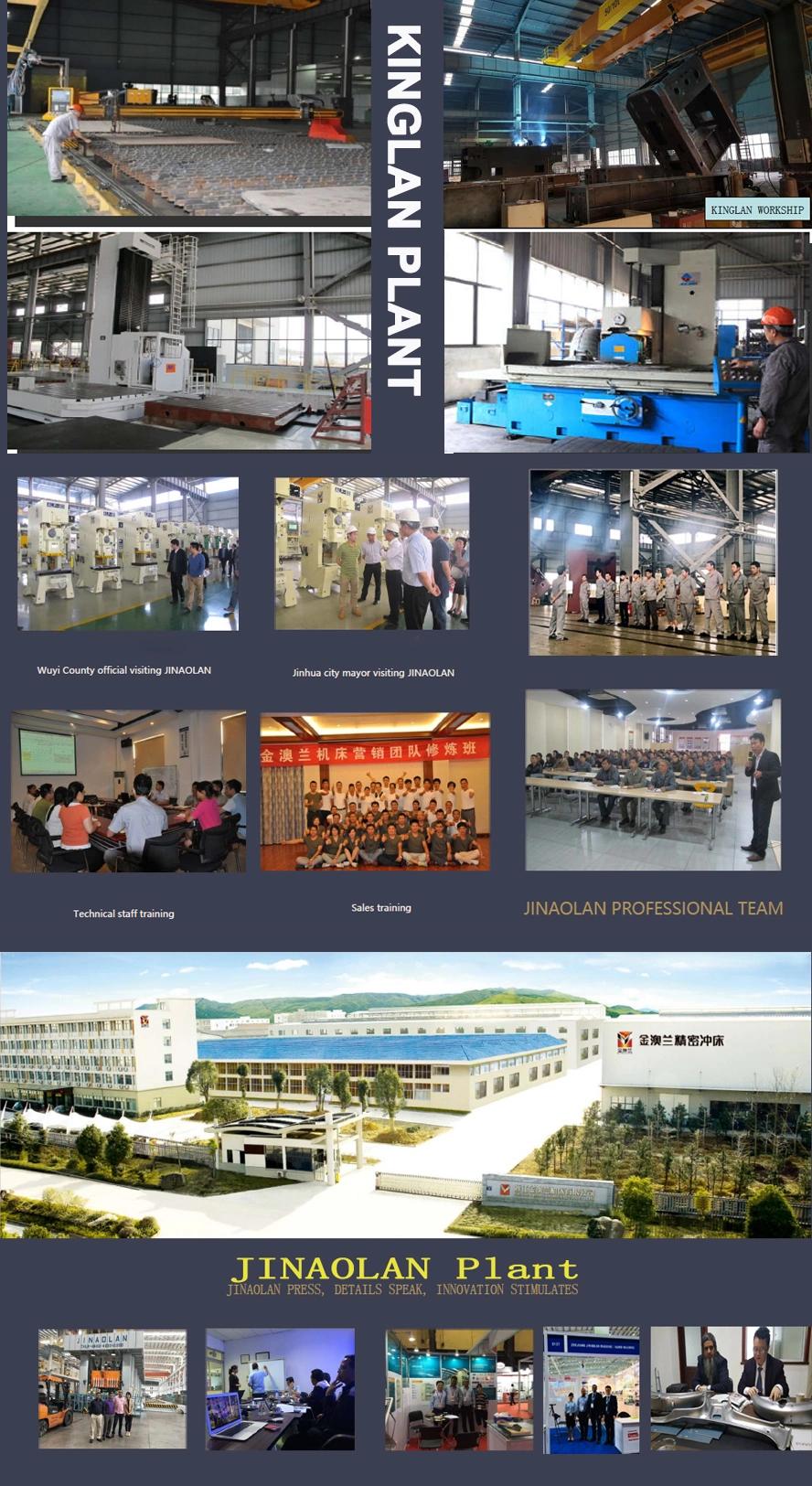

- Trademark:KINGLAN

- Transport Package:Standard Export Package

- Manufacturing Technology:Automation Technology

- Origin:Wuyi, Zhejiang

- HS Code:82072010

- Production Capacity:500PCS Per Month

Description

Project Description

Our produced products

Punching machine

Certificate

Contact US

To Customers:We could provide the whole line solution including power press, feeder and decoiler, molds, manipulator, robot Iron-hand,etc.

Our technologists come from Japan,Germany, and Taiwan. At present,our quality customers includ GM, GREE,Ford,ZOTYEAUTO,VW,Midea,Vanward,Aux,ect.

Power presses are used to shear, punch, form, or assemble metals or other materials by using tools or dies attached to slides or rams. Used in large industries for heavy operations, power presses can be powered by pneumatic, hydraulic or mechanical means.

In all our years of manufacturing quality power presses and other power press products, we have made it our goal to put the customer first. We believe in offering the right solution to meet your needs, whether it is having the right parts to fix your existing machines, the presses you need at an affordable price, or the ongoing support to keep your machines in top condition.

Our goal is to provide our customers with the highest level of quality, whether it is in our power presses and other press designs, or in our customer service dealings with each customer. We have been in business for 20years, which makes us uniquely suited to meet the needs of our varied customers. Contact us today to learn more! Thanks!