Factory Mold Injection Plastic Parts

Suzhou Get Plastic Technology Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:PA66+GF

- Mould Cavity:Multi Cavity

- Surface Finish Process:Heat Treatment

- Shaping Mode:Plastic Molding Die

- Application:Household Appliances, Furniture, Commodity

Base Info

- Transport Package:Wooden Cases or According to You

- Warranty Period:12 Months Warranty

- Lead Time:30-45 Days

- Sample Day:7-10 Business Days

- Mould Life:300000-3000000 Shots

- Use:Medical Application

- Shape:Customized

- Mould Delivery:by Air,Sea

- Mould Material:Different Grade: P20, S136, 2316, H13, etc.

- Colour:Customized

- Customized:Customized

- Standard:MISUMI

- Certification:TS16949, ISO

- Installation:Mobile

- Design Software:Pro-E

- Runner:Cold Runner

- Model NO.:JT-0842

- Specification:Customized

- Trademark:Get plastic

- Origin:Suzhou, Jiangsu, China

- HS Code:8480719090

- Production Capacity:600 Set,Sets Per Year

Description

Basic Info.

Model NO. JT-0842 Runner Cold Runner Design Software Pro-E Installation Mobile Certification TS16949, ISO Standard MISUMI Customized Customized Colour Customized Mould Material Different Grade: P20, S136, 2316, H13, etc. Mould Delivery by Air/Sea Shape Customized Use Medical Application Mould Life 300000-3000000 Shots Sample Day 7-10 Business Days Lead Time 30-45 Days Warranty Period 12 Months Warranty Transport Package Wooden Cases or According to You Specification Customized Trademark Get plastic Origin Suzhou, Jiangsu, China HS Code 8480719090 Production Capacity 600 Set/Sets Per YearProduct Description

Factory mold injection plastic parts| Product name | Factory mold injection plastic parts |

| Plastic Parts Material | ABS,PBT,PC,PMMA,POM,PP,PPS,PVC,TPE,TPO,TPU,ETC |

| Mold Standard | DME,HASCO,etc |

| Runner | Hot Runner/Cold Runner |

| Process | CNC, high speed carve, EDM ,wiring-cutting, drill, polish etc |

| Product Design Software | UG, CAD, PRO-E, Solid Works etc |

Prouct Application:Household Appliances;Furniture;Commodity;Electronic;Home Use;etc

Suzhou Get Plastic Technology Co., Ltd

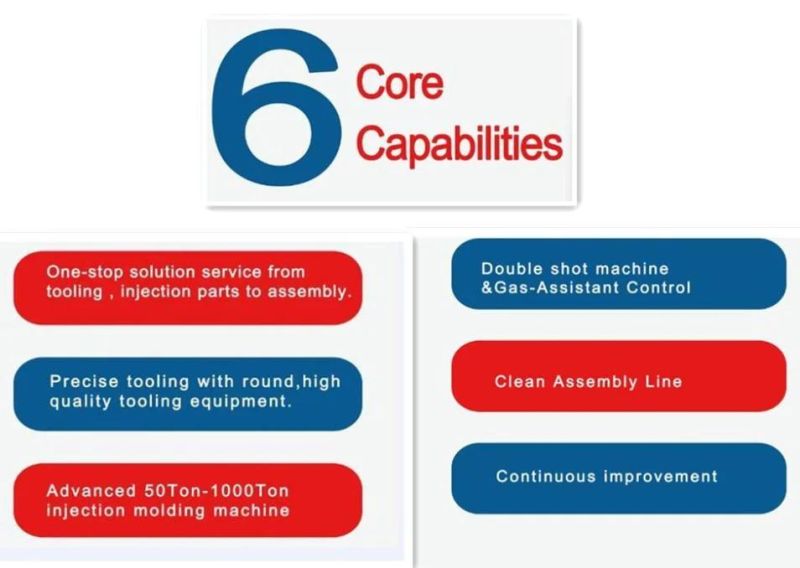

is a solution expert and full service custom plastic Injection Molding company.

Built from the ground up in 2007 to facilitate current and future needs of our customers, Suzhou Get-Plastic Technology Co., Ltd is a state of the art facility locates at Suzhou, China with the ability to design and manufacture precision tooling, products by injection molding and assembly for ODM and OEM customers with ISO9001 & IATF16949 certification.

Currently we are well-equipped with sets of advanced molding process equipment, plastic injection molding machinery and testing instruments to support customers get what they want to get and bring it to life.

Q&A:

1, do you perform heat treatment of tools in your factory ?

Get Plastic: No, we don't. outsourcing for heat treatment of tools

2,what hardness of tools you can achieve ?

Get Plastic: S136 hardness:48-54HRC;8407 stainsteel hardness: 48-52HRC.1.2738HH Hardness:33-38HRC

3,which type of surface eroding do you use ?

Get Plastic:VDI

4,which types of standard european mold parts do you use ? (hasco, meusburger etc...)

Get Plastic: We stick to Hasco standard normally.

5,does your factory satisfies any quality standard (do you have any quality certificate)?

Get Plastic: Yes, IATF16949,ISO9001