High Cooling Efficiency Copper Mould Pipe for CCM

Henan Shengmiao Instrument Co., Ltd.- Demoulding:Pull Core

- Material:Copper

- Application:Continuous Casting Machine

- Warranty:6 Months

- After-sales Service:Provided

- Surface Treatment:Coat-Plating

Base Info

- Specification:according to request

- Transport Package:by Woonden Box for Copper Mould Pipe

- Condition:New

- Customized:Customized

- Certification:ISO 9001

- Mould Life:500,000-1,000,000 shots

- Average Wall Thickness:>3mm

- Using Hardness:>HRC45

- Model NO.:CMT001

- Trademark:Shengmiao

- Origin:China

- HS Code:8454902100

- Production Capacity:50, 000pieces,Year

Description

Melting Point

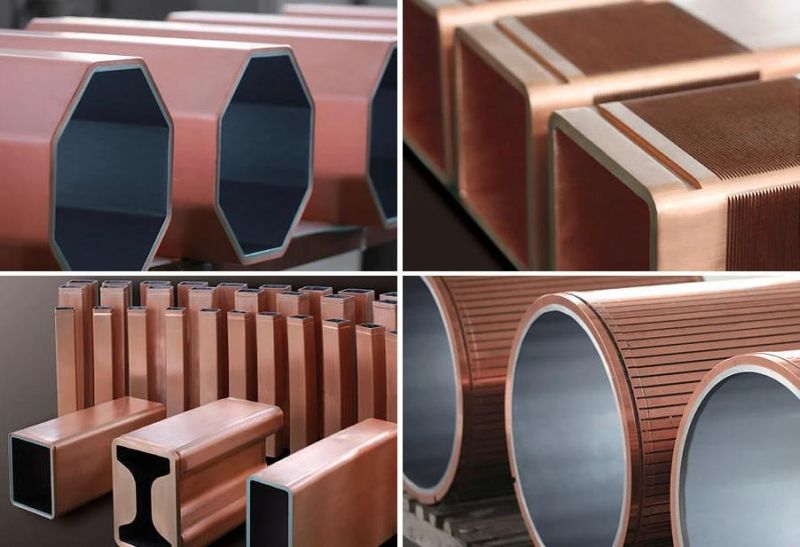

6. High cooling efficiency copper mould pipe for CCM Coating

In order to increase the erosion resistance and service life the casting mould tubes, we always dedicated to research special coatings. The mould tubes can be coated with our different types of internal surface coating: Cr, Ni-Co, Ni-Fe, Ni-Co-Cr. The coating thickness recommended by us has been controlled in the best range.

7. Size of High cooling efficiency copper mould pipe for CCM

We supply all kinds of molten steel crystallizer Copper Mould Tubes of all sizes and dimensions, produced exactly as per the required drawing. The Sizes for Copper Mould Tubes is enlisted as under:

8. Advantages of Shengmiao High cooling efficiency copper mould pipe for CCM

CHROME COATING

MOULD & PLATE COATINGS

As for the coating of copper mould plates, based on our years of experience, we are able to provide Chrome coating, Ni-Cr coating, Ni-Fe coating and Ni-Co coating to meet the demand of various customers.

We provide Crystallizer Copper tube Steelmelting accessory as per the customer's specific requirements.