Plastic Injection Mould Plastic Parts Injection Molding

Qingdao Haixin Steel & Plastic Products Co., Ltd.- Plastic Material:ABS, PP, PE, PVC, PC, PA, etc.

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Warranty:1years

- Process Combination Type:Compound Die

Base Info

- Transport Package:Customized

- Color:Customized

- After-sales Service:1years

- Customized:Customized

- Standard:HASCO

- Certification:TS16949, CE, ISO, FDA

- Installation:Mobile

- Design Software:UG

- Runner:Hot Runner

- Application:Household Appliances, Furniture, Commodity, Electronic, Home Use

- Model NO.:HX-1005

- Specification:Custom According to Drawing or Samples

- Trademark:Haixin

- Origin:China

- HS Code:84807190

- Production Capacity:10-20PCS,Month

Description

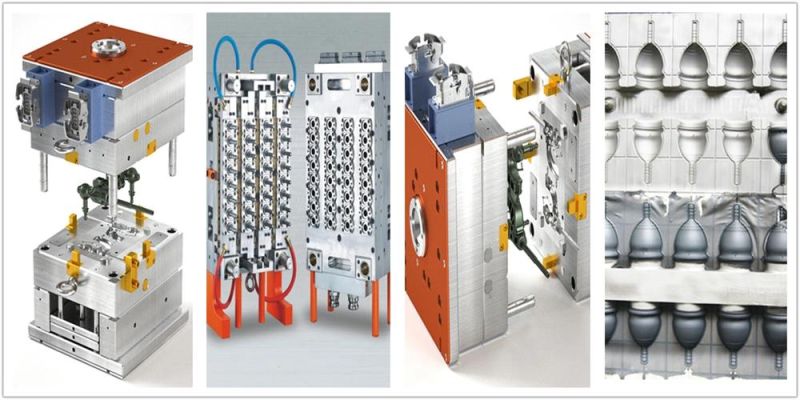

Product View:

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

The plastic Injection molding process refers to the process of making a certain shape of semi-finished parts by pressing, injecting, cooling and separating molten raw materials. The general process of injection molding production is: raw materials → synthetic resin → plastic preparation → plastic molding

Injection molding production includes three production processes: the first production process is to produce synthetic resin from raw materials through polymerization reaction; the second production process is to add additives to get plastic, which is the raw material for injection molding; the third production process is to use various molding processing methods to make it into injection molding with certain shape and use value according to plastic properties product