Plastic Stool Wholesale Design Moulding

ZHEJIANG MELEE MOULD CO., LTD.- Plastic Material:PE

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Warranty:Always

- Process Combination Type:Single-Process Mode

Base Info

- Transport Package:Wooden Case

- Tooling Time:35days

- Mould Life:800k Shots

- Mould Material:P20,718...

- Size:as Your Request

- After-sales Service:Always

- Customized:Customized

- Standard:HASCO

- Installation:Manual Installation

- Design Software:UG

- Runner:Hot Runner

- Application:Commodity

- Model NO.:MELEE MOULD -977

- Specification:SGS

- Trademark:OEM

- Origin:Huangyan, Taizhou

- HS Code:8480710090

- Production Capacity:350sets ,Year

Description

Basic Info.

Model NO. MELEE MOULD -977 Application Commodity Runner Hot Runner Design Software UG Installation Manual Installation Standard HASCO Customized Customized After-sales Service Always Size as Your Request Mould Material P20,718... Mould Life 800k Shots Tooling Time 35days Transport Package Wooden Case Specification SGS Trademark OEM Origin Huangyan, Taizhou HS Code 8480710090 Production Capacity 350sets /YearProduct Description

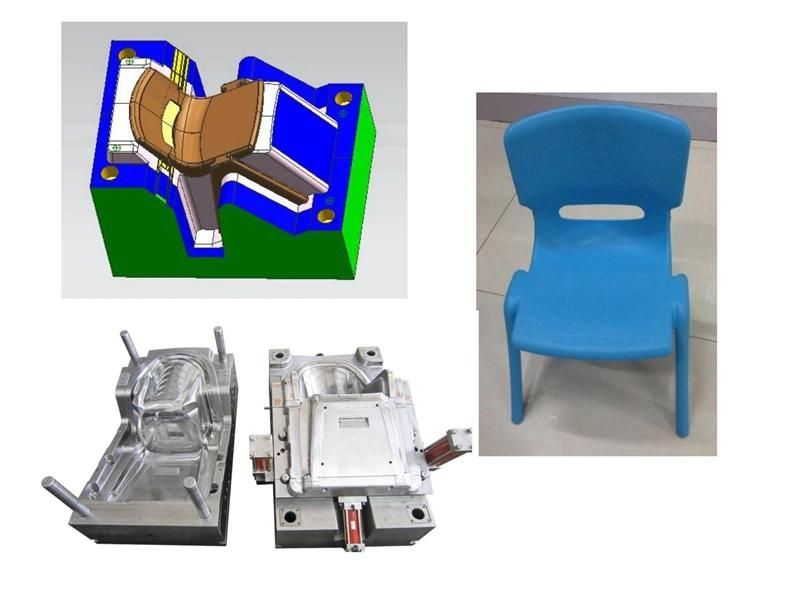

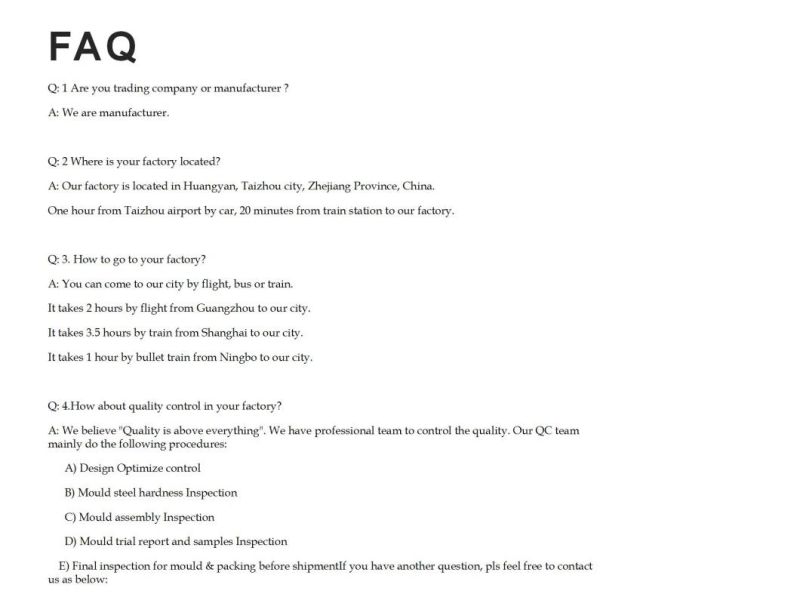

Detail description of Plastic Mould /MoldProduct Name: Chair mould/mold

Product material: PP

Plastic Mould /Mold cavity: 1cavity

Plastic Mould /Mold material: P20, 718

Plastic Mould /Mold life: 800k shots

Runner system: Hot runner

Ejection system: Gas ejector

Plastic Mould /Mold features: Good quality

Injection cycle time: 30seconds

Tooling time: 35days

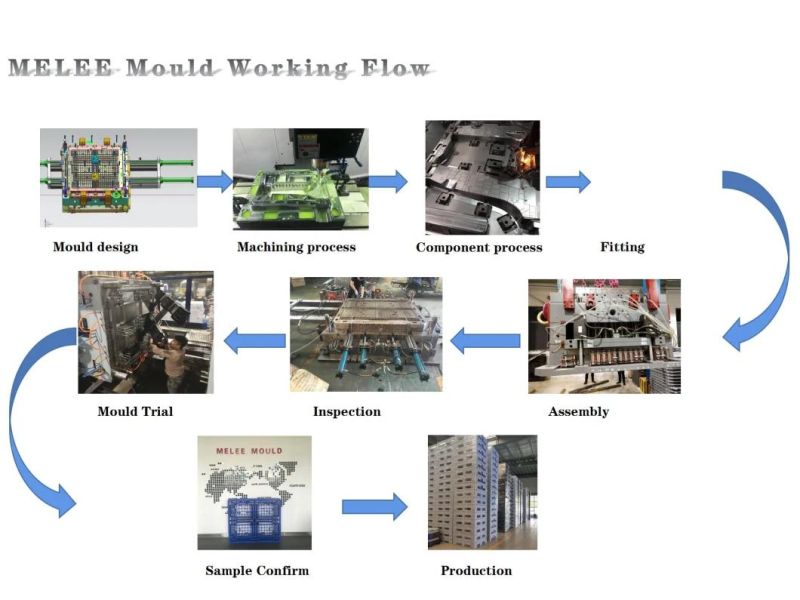

MELEE MOULD Co., Ltd service process

1. Design/sample: Product, mould, etc.

2. Discussion: Mould material, cavity number, price, runner, payment, etc.

3. Order placedA: Ccording drawing or your samples.

4. Design mould: We will send mould design to customer for confirmation

5. Mould tooling: We start to make mould after mould design confirmed

6. Mould processing: Send pictures to customer to let customer what we doing

7. Mould shot trial: Send mould shot trial samples to customer to confirm mould quality

8. Delivery: Ship mould after mould quality confirmed.

?. Detail description of plastic mould/mold

| |||||||||||||||||||||||||||

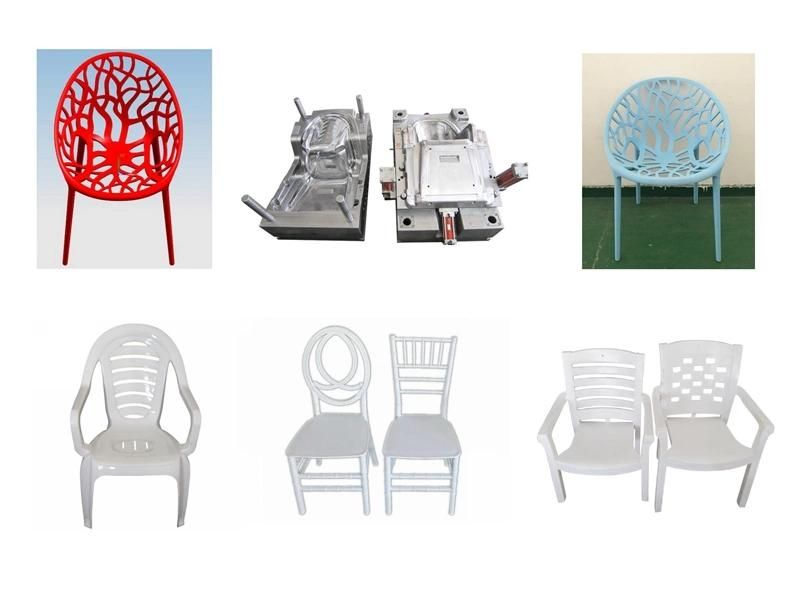

MELEE specializes in manufacturing and supplying various plastic injection moulds, die casting molds.

We provide various molds & dies to the clients from Germany, USA, Spain, Italy, Russia and so on.

"High quality" and "Good service" is the base of MOLDIE business, because our mission is:

To Be One of the Best Industrial Suppliers.

We own ISO 9001: 2008 certificated and SGS Certificated.

Plastic injection mould advantages:

1.Professional design team

2.Professional mold design team

3.Professional mold making machines

4.Professional mould and product QC and tec. team

5.Rich mould making experience with different clients from various country

Special info.:

Brand | MELEE |

Model | MLD-13-MD075 |

Mold Base | LKM, HASCO, DME or your requirement |

Mold Material | 45#, P20, H13, 718, 1.2344, 1.2738 and so on |

Standard | HASCO, DME, MISUMI, PUNCH and so on |

Product Material | PC/ABS, ABS, PC, PVC, PA66, POM or other you want |

Runner | Cold/Hot Runner |

Gate Type | Side gate, Sub gate, Pin point gate, Edge gate etc |

Mould Weight | 50kg-15Ton |

Injection Machine Type | 80-1500Ton |

Standard for Product Appearance for graining | MT(Mold Tech), YS, HN Series |

The Way of Color Contrast for Plastic | RAL PANTONE |

Certificated | ISO 9001:2008 Certificated, GSG Certificated |