Double Color Plastic Injection Mold for Auto Parts

Yuyao Xianghao Mold Technology Company Limited- Surface Finish Process:Polishing

- Mould Cavity:Multi Cavity

Base Info

- Two Color Injection Molding Double Color:Two Material Injection Molding

- Double Color Mold Design and Production:Over Mold,Double Color Mold

- Double Color Injection Mold:Double Color Plastic Injection Mold

- Plastic Injection Mold From Double Color:Good Quality Double Color Mold

- Double Color Mould:Two Color Mold

- Two Color Molding:Double Color Mold

- Double Injection Molding:Two Shot Mold

- Double Shot Injection Moulding:Double Injection Mold

- Standard:DME

- Customized:Customized

- Certification:TS16949

- Design Software:UG

- Installation:Fixed

- Runner:Hot Runner

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use

- Process Combination Type:Single-Process Mode

- Plastic Material:HDPE

- Model NO.:double color plastic injection mold

- Over Molding:Double Shot Molding

- Dual-Injection Molding:Insert Molding

- Transport Package:Steel Box

- Specification:CE ROHS

- Trademark:DARRPW

- Origin:China

- HS Code:8480410010

- Production Capacity:20sets Mold Per Month

Description

Basic Info.

Model NO. double color plastic injection mold Plastic Material HDPE Process Combination Type Single-Process Mode Application Car, Household Appliances, Furniture, Commodity, Electronic, Home Use Runner Hot Runner Design Software UG Installation Fixed Certification TS16949 Standard DME Customized Customized Double Shot Injection Moulding Double Injection Mold Double Injection Molding Two Shot Mold Two Color Molding Double Color Mold Double Color Mould Two Color Mold Plastic Injection Mold From Double Color Good Quality Double Color Mold Double Color Injection Mold Double Color Plastic Injection Mold Double Color Mold Design and Production Over Mold/Double Color Mold Two Color Injection Molding Double Color Two Material Injection Molding Over Molding Double Shot Molding Dual-Injection Molding Insert Molding Transport Package Steel Box Specification CE ROHS Trademark DARRPW Origin China HS Code 8480410010 Production Capacity 20sets Mold Per MonthProduct Description

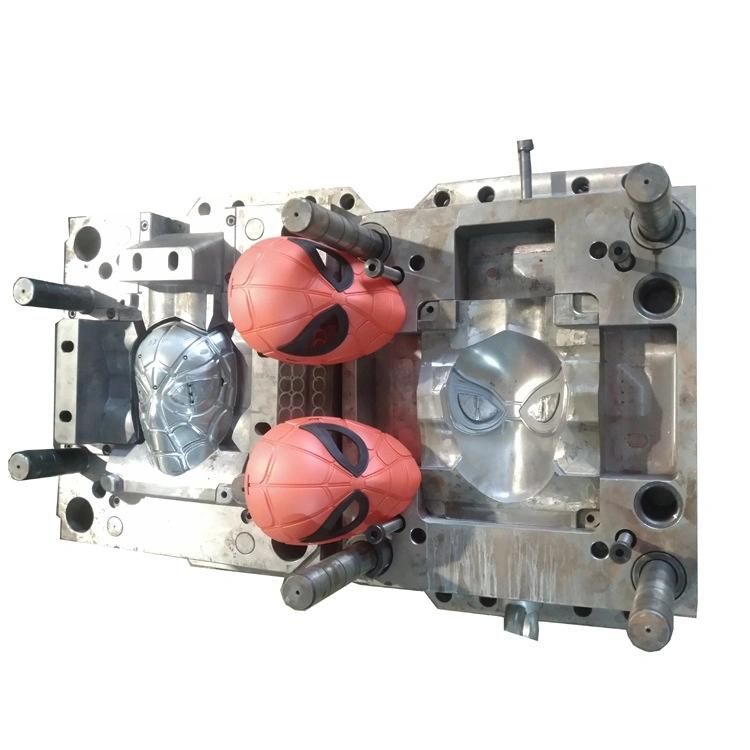

Double Shot Injection Moulding

Double injection mold

Double injection molding

Two shot mold

Two-Color Molding

Double color mold

Double color mould

Two Color Mold

Plastic Injection Mold from Double Color Mold

Good quality double color mold

Double color injection mold

Double color plastic injection mold

Double color mold design and production

Over mold/Double color mold

Two color injection molding Double color plastic mould

Two material injection molding

Over molding

Double-shot molding

Double-shot

Dual-injection molding

Insert molding

Double-shot mold

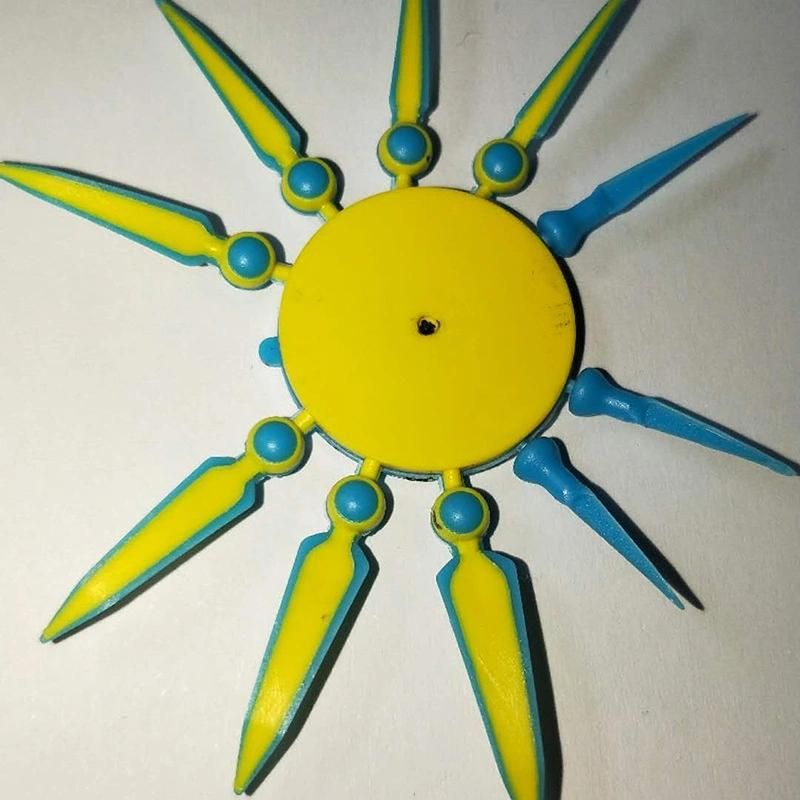

Over mold material: PP+TPE, PP+TPR, ABS+TPE, ABS+TPR, PC+TPE, PA+TPE

Two-Color Molding may also be referred to as: 2-Shot molding, Bi-injection molding, Co-injection Molding, or Multi-Shot Injection Molding

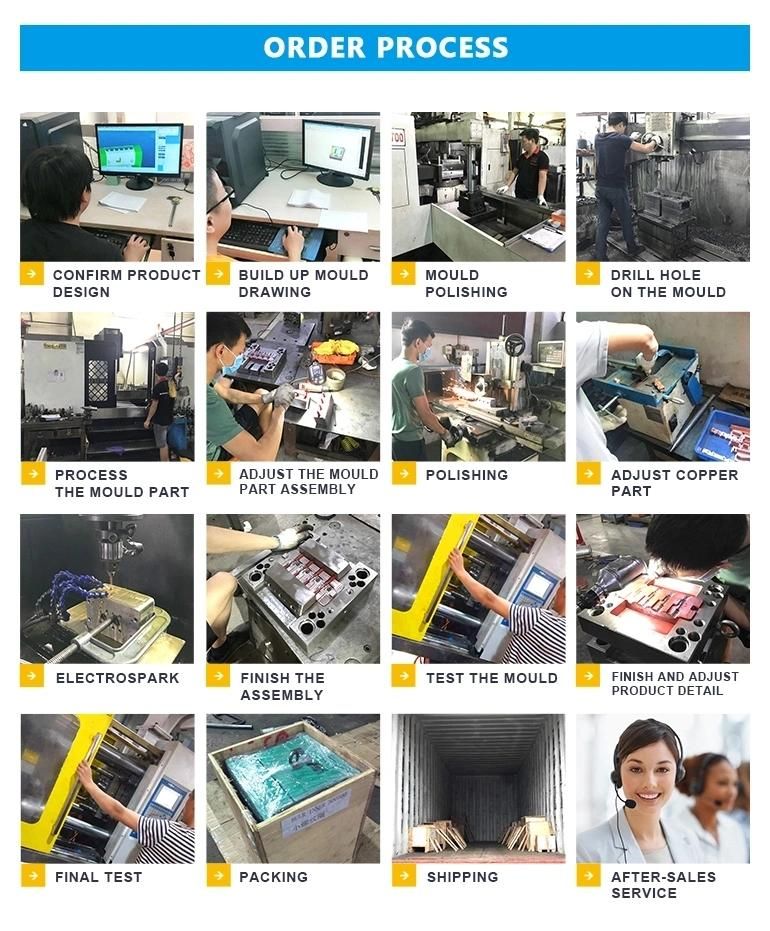

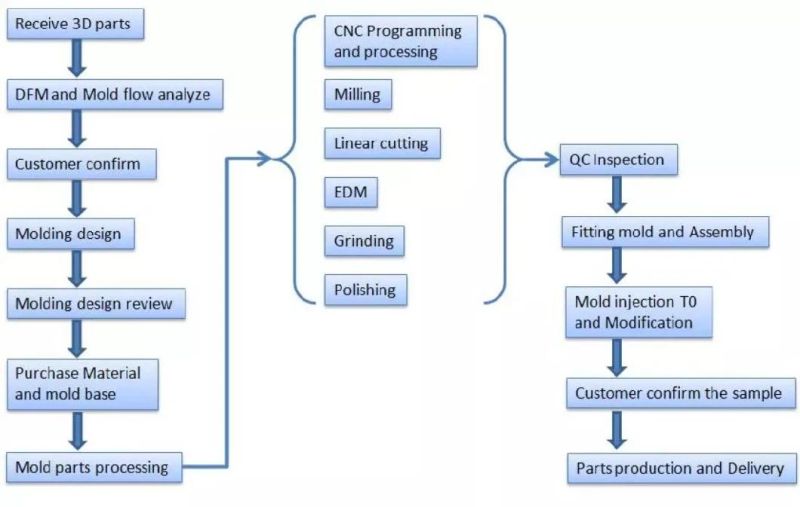

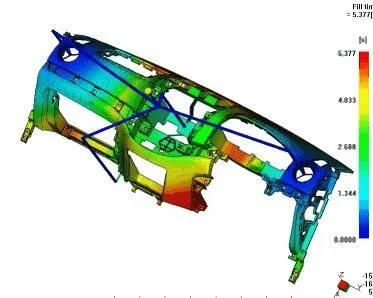

This technology produces a part with two different colors and/or materials in a single operation. The machine has two injection units: One vertical and one horizontal. By using a rotating mold, the machine automatically produces a substrate of one resin or color and overmolds the part with the second resin or color.

Denver Plastics provides two-shot two-color molding for a variety of industries. Typically, two-shot two-color molding is used for soft-touch over-molding grips in power tools, outdoor equipment, medical equipment, electrical equipment, consumer products, and automotive components. This process reduces part costs by eliminating labor, improving quality, and eliminating post-molding steps such as sonic welding, assembly, snap fits or fasteners. The cost advantages become obvious, especially when applied to high volume parts.

| . Item Name | double color button mold |

| 2. Product color | as customer's requirement |

| 3. Mould material | 2378, 718, NAK80, S136 etc. |

| 4. Mold Base | LKM, FUTA, HASCO, DME, etc. |

| 5. Cavity | single, multi |

| 6. Shot Runner | cold or hot runner_ point way ,side way,follow way,direct gate way,HASCO/DME/YUDO etc. |

| 7. Mould Life | more than 500K shots |

| 8. Surface finish | polish |

| 9. Package | wooden case or as your request |

| 10. Transportaion | by sea or air |

| 11. Lead time | 30- 40 days |

| 12. Trade terms | FOB Shenzhen/ Hongkong |

| 13. Payment terms | T/T, L/C, Western Union, Cash |

| 14. Export country | Europe country, the USA, Germany, Japan, Korea etc. |

| 15.Certification | ISO9001:2000 |