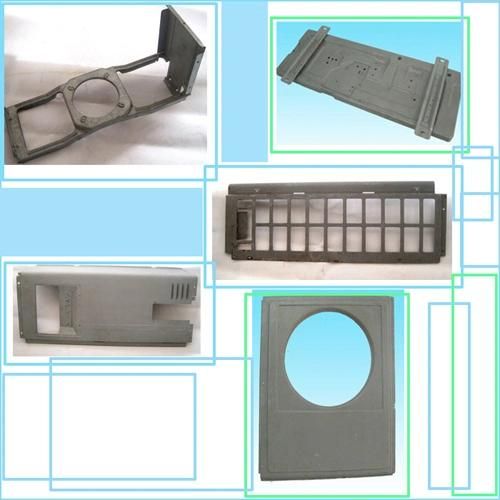

Metal Parts for Refrigerator, Washing Machine, Air Conditioner, Housing Appliances.

Qingdao Higrade Moulds & Products Co., Ltd.- Process Combination:Progressive Die

- Technics:Forming Die

- Processing Method:Punching and Shearing Mould

- Material:Hard Alloy and Steel Bonded Carbide

- Manufacturing Technology:Computer Technology

- Driving Motor Type:Permanent Magnet

Base Info

- Transport Package:Wooden Case

- Scope of Application:Home Appliances

- Product Material:SUS304,SPCC

- Die Material:Cr12MOV,SKD61,SKD11,Skh-9, 45#

- Certified:ISO9001: 2008

- Parts Detection Method:Geometric Detection

- Milling Speed:High Speed

- Mold Cavity Technology:EDM Milling

- Model NO.:HRD-111003

- Specification:ISO9001: 2008

- Trademark:Higrade

- Origin:Chian Qingdao

- HS Code:8480710090

- Production Capacity:80000

Description

Basic Info.

Model NO. HRD-111003 Mold Cavity Technology EDM Milling Milling Speed High Speed Parts Detection Method Geometric Detection Certified ISO9001: 2008 Die Material Cr12MOV,SKD61,SKD11,Skh-9, 45# Product Material SUS304,SPCC Scope of Application Home Appliances Transport Package Wooden Case Specification ISO9001: 2008 Trademark Higrade Origin Chian Qingdao HS Code 8480710090 Production Capacity 80000Product Description

{Product material}: SUS304, SPCC and so on{Scope of application}: Home appliances

{Die types}: Progressive

{Mould Life}: 50~100 shots

{Tolerances}: 0.02

{Processing Date}: 35~45 days

{Spare parts}: PUNCH, MISUMI and so on

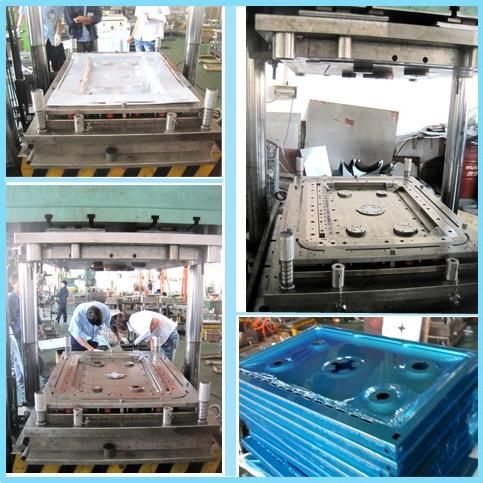

{Equipment}: 400T Punch

{Produce equipment}: 315T Hydraulic machine/press, 400T200T160T Punch (With the belt feeding machine), 110T, 80T, 40T Punch equipment, Can meet the need of mass production and testing.

{Service content}: Designing and manufacturing for metal mould and products.

{Main customers}: Haier, Hisense, Midea, Siemens, Sanyo, Electrolux, Toyota, KIA, Foton, SGMW, SKYWORTH etc.

{Main export markets}: Japan, Korea, Thailand, Russia, Germany, Britain, Norway, Italy, Spain, Turkey; America, Brazil, Argentina; South Africa Egypt; Iran, Pakistan, India etc...

{Mold paint}: Painting color depends on customer requirements

(Packaging: Wooden case)

The first trial success rate is above 95%

{Quotation time}: We will quote in 24 hours after receiving the customer's drawings.

{Data needed to offer}: 2D/ 3D drawing or samples

{Quotation}: Including the accurate price/stage/life and process time.

{The profile}: 2D/3D drawing or samples

{Project Manager}: Concentrate on project tracking and after service

{Engineer}: 30-50 excellent engineers, have many years experience and English communicate well.

{Warehousing and logistics}: The purchase department use EPR system to make sure buying materials in time.

{Fitter technician}: 100-130 experienced workers can meet the customer request of batch production.

{Quality department}: 15 members quality control workers, measuring the mould and parts by CMM and projector.

{Domestic delivery}: Logistics transportation

{Delivery to overseas}: FOB/CIF/DDU by sea shipping or air shipping

Mold factory, fitter & quality inspection work to be done:

| Fitter | Quality testing |

| First die by the fitter for a thorough inspection of the mold as follows: | Die size (I* W * H) |

| Die accessories are complete | If the mold specification matching and customer equipment(height, the size of a mould, mould position) |

| Ensure the mold factory 100% acceptance (including:assembly, test mode etc.) | There is no die shank (reasonable) |

| According to the customer request is equipped with the factory. | Die code is complete (item, process name) |

| Die appearance: template logo are complete; the surfacerust are clean, then coated with anti rust oil, wooden packing. | Whether to need to mold brand |

| With mold factory data | On the,In the lower limit of a column is complete, paint color and reasonable |

| Mold inserts, punch is complete | |

| Screw dismounting have wear / screw holes are offset | |

| The die structure is reasonable / mould factory data is complete |