Laser Machine Laser Vascular Removal Vein Equipment Casing Machine

Green Vitality Industry Ltd.- Process Combination Type:Compound Die

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Polishing

- Application:Household Appliances, Furniture, Commodity, Electronic, Home Use

Base Info

- Origin:China

- Trademark:GVI

- Specification:customized

- Transport Package:Pry Wood Box

- Steel:H13 S136

- Customized:Customized

- Standard:HASCO

- Certification:CE, ISO, FDA

- Installation:Fixed

- Design Software:AutoCAD

- Runner:Cold Runner

- Model NO.:kidyson mold

- HS Code:8480710090

- Production Capacity:500 Sets ,Year

Description

Basic Info.

Model NO. kidyson mold Runner Cold Runner Design Software AutoCAD Installation Fixed Certification CE, ISO, FDA Standard HASCO Customized Customized Steel H13 S136 Transport Package Pry Wood Box Specification customized Trademark GVI Origin China HS Code 8480710090 Production Capacity 500 Sets /YearProduct Description

Laser Machine Laser Vascular Removal Vein Equipment Casing MachinePlastic ABS Material Waterproof Electric Enclosure Molds

Basic Information for Plastic Part & Mould:

| Part Name | Plastic Parts | Mold Type | Plastic Injection Mold |

| Part Material | PC, ABS, PP, PA, PA+GF, PBT, BMC, PMMA, PC+ABS, PP+TD20%, POM, PE, PVC etc. | Mould Steel Material | NAK80, S136, SKD61, P20,1730hh, 2738hh, 718h, H13, BPMHH, 2343hh etc. |

| Part Size (mm) | as per Drawing, Sample, or Design | Mould Dimension (mm) | as designed, 1200*1000mm max. |

| Part Weight (g) | as per Drawing, Sample, or Design | Mould Weight (kg) | as designed, 10 tons max. |

| Injection Machine (Ton) | TBA when quote | Mould Cavity No. | Single or Multiple |

| Injection Cycle (s) | TBA when quote | Runner System | Hot or Cold runner, pin-point gate, etc. |

| Tolerance | as required | Mold Components Standards | DME, LKM, HASCO or equivalent |

| Secondary Operations | Silk-screen Printing, Electroplating, Painting, Coating, Assembly, Package etc. | Surface Treatment | Mirror Polish, Matt, Texture VDI etc. |

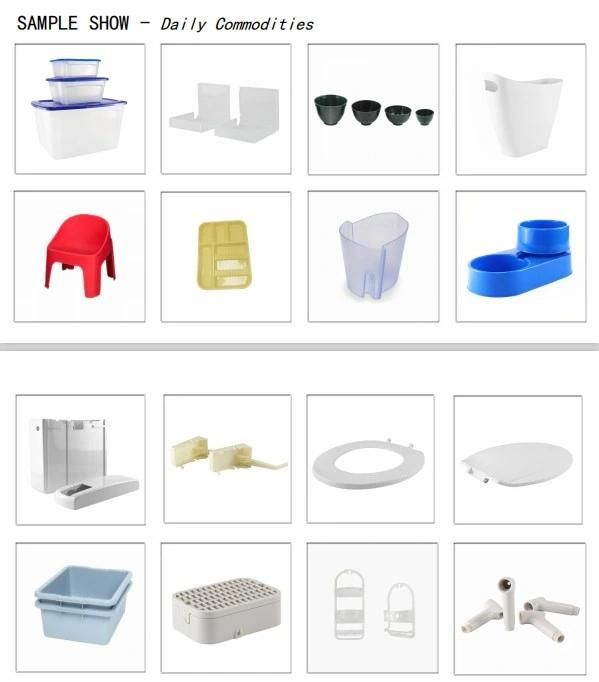

| Application | Daily Commodities | Mould Life (Shots) | 100,000 ~ 1,000,000 shots as required |

| Special Requirements | Food Grade, BPA free, UV resistant, Fire Resistant, Waterproof etc. if required | Special Requirements | Moldflow Analysis if request, or as customers' request |

Company Introduction

Green Vitality Inductry Co., Ltd is a professional injection mold maker extablished in 1993. We have been delicated to the mold making industry for more than 20 years. Green Vitality has accumulated rich experience and build up a strong steady engineering and manufacturing team, which supports us to become a reliable supplier as well as the strategic partner of customers worldside.

We are offering our customer one stop service for plastic part which includes moldflow, part design , tooling design, tooling manufacture, injection molding, secondary operation and part delivery.

Commitment to quality:

- Continually maintaining and improving the effectiveness of our quality management system.

- Periodic review of current quality policy and objectives to ensure its effectiveness and suitability.

- Quality First and Service First is our pledge. In order to serve and support our clients better, we would establish a special team called Technology and Cost Team. So Best Practice (top quality and competitive price) will be submitted to you in the shortest time. Green vitality sincerely welcomes you and hopes to be the most suitable and steadiest partner of you.

- We promise, and we do!

2) Part material: ABS, PP, POM, PC, PS etc.

3) Part Annually forecast or minimum order quantity 4) Specifical requirement: such as food-grade, medical grade, UV resistant.

5) Plastic components Application 12. What information needs for quotation & design of Molds? 1) Mold Runner type: cold or hot

2) Mould steel material: P20, 718, 2738, H13, S136 an so on. 3) Mold Cavity 4) Mold Life 5) Mold Standard: LKM, DME or HASCO or equivelent 6) Surface treatment requirements 7) The tonnages of Injection Machine

8) Plastic components function

9) Other key points

Thank you !