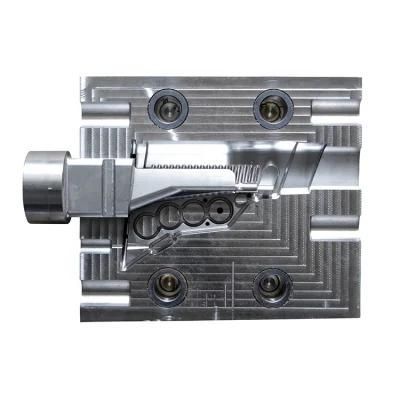

Plastic Injection Mould Bottle Mould Customized Mould Tooling Design

Zhejiang JMT Technology Co., Ltd.- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Warranty:1

- Process Combination Type:Single-Process Mode

Base Info

- Trademark:JMT

- Transport Package:Wooden Case

- After-sales Service:1

- Customized:Customized

- Standard:HASCO

- Certification:TS16949, ISO

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Application:Car

- Origin:Taizhou Huangyan

- HS Code:84807100

- Production Capacity:1

Description

FAQQ1.How can I get a Quotation?

FAQQ1.How can I get a Quotation?1) 3D with stp.(preferred) igs, st.prt. format

2) 2D drawing for tolerance/material/surface finish/test requirement/regulations

3) Quantity (by order, month and a Year)

We can help you complete above for ODM project

Q2.How do you ensure product quality?

As you can see above, we apply assessment, planning, monitor at every single process. Some bullet points:

1)Apply APQP Product development process

2)Layemphasis on prevention and planning

3)Once a year ISO9001, IATF 16949 audit and refreshing

4)Designforquality (poke-yoke as much as possible)

Q3. How do you ensure on time delivery?

1) Detailed planning, details to per hour/person/machine number/stakeholder…

2) Main material driving management system

3) Daily progress meeting, a recovery plan will be reviewed by management team once any key chain is delay.

4) If delay happen on delivery, Goutech will provide customer 1% discount for one week delay, up limit to 10%

Q4. What is your defective part handling process

WTmold have good traceability record for people/machine/parameter/material batch/inspection, that will help quick quarantine

defect parts, find out root cause and apply prevention method

1)Quarantine defect batch raw/semi/finish materials

2)Analysis root cause

3)Add prevention and inspection method

4)Produce new part and replace defect part on customer site