Plastic Injection Mould for Bluetooth Speaker Loudspeaker Box Music Player

Green Vitality Industry Ltd.- Process Combination Type:Injection Cavity

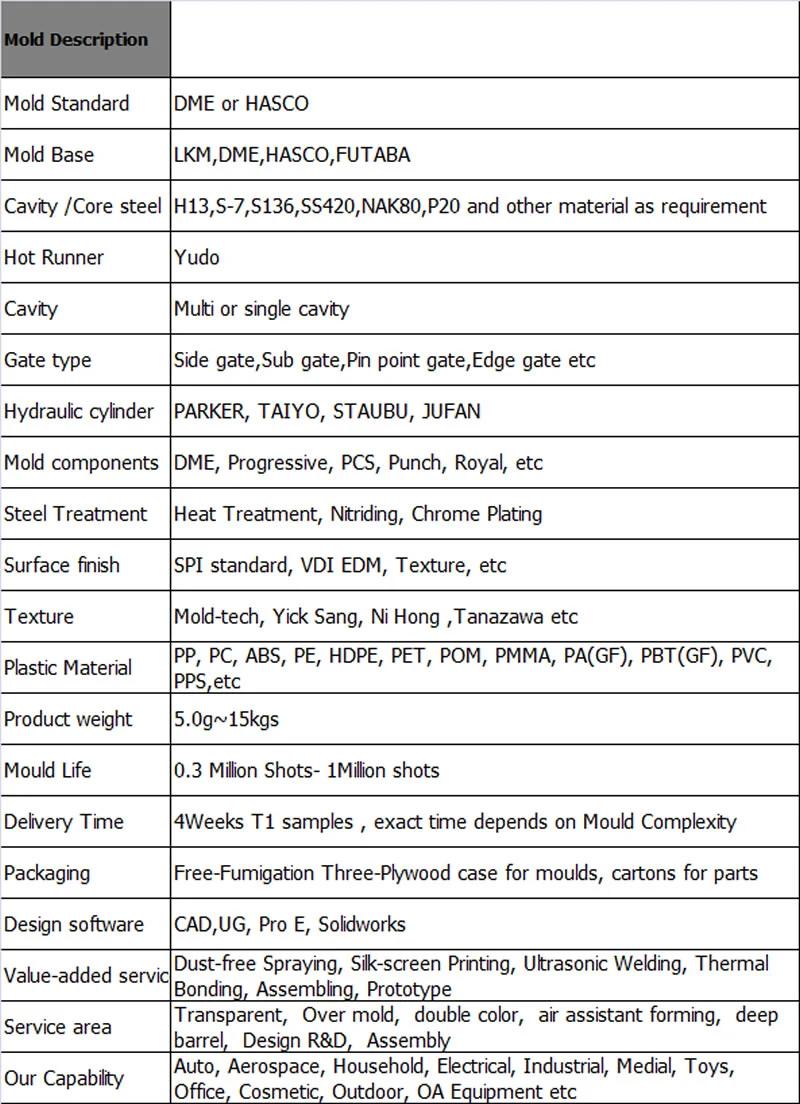

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Electronic, Medical Products

Base Info

- Transport Package:Pry Wood Box

- Steel:S136 H13 718h P20 Nak80 Optimax 8407

- Customized:Customized

- General Material Used:PC PE PS Acrylic ABS TPU PP PVC as POM PA PMMA

- Standard:DME

- Certification:ISO

- Installation:Fixed

- Design Software:AutoCAD

- Runner:Cold Runner

- Model NO.:GreenVitality Mold

- Specification:Custom Products Series

- Trademark:GV

- Origin:China

- HS Code:8480710090

- Production Capacity:500 Sets ,Year

Description

Basic Info.

Model NO. GreenVitality Mold Runner Cold Runner Design Software AutoCAD Installation Fixed Certification ISO Standard DME Customized Customized General Material Used PC PE PS Acrylic ABS TPU PP PVC as POM PA PMMA Steel S136 H13 718h P20 Nak80 Optimax 8407 Transport Package Pry Wood Box Specification Custom Products Series Trademark GV Origin China HS Code 8480710090 Production Capacity 500 Sets /YearProduct Description

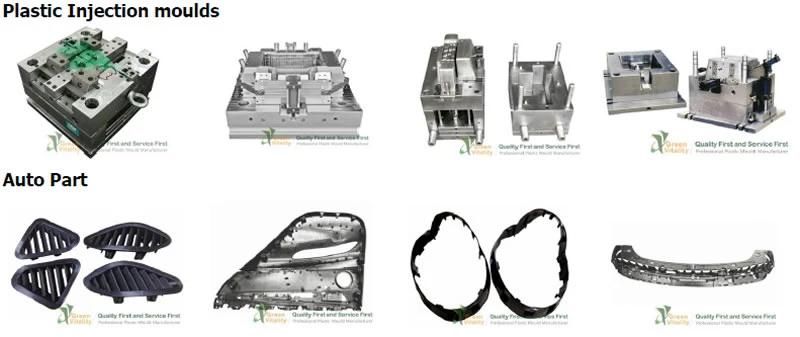

Plastic injection mould for Bluetooth Speaker Loudspeaker Box Music Player

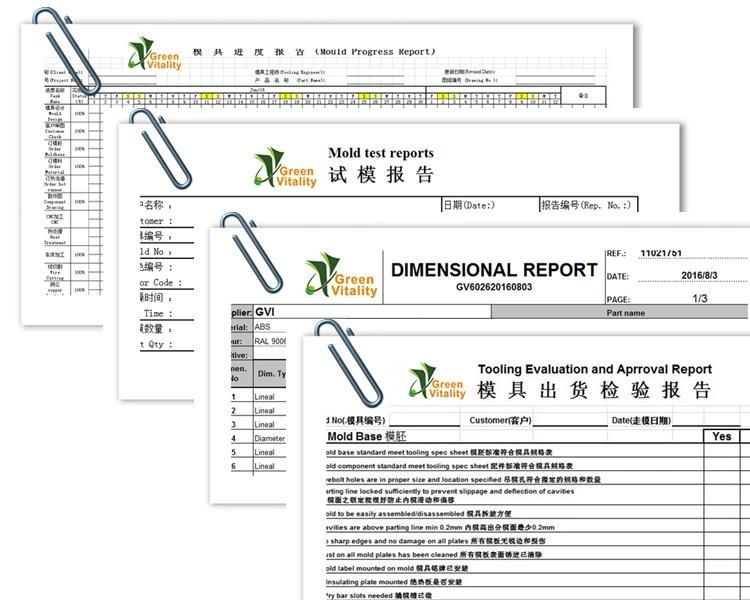

Operation Flow:

Green Vitality Mold uses professional form and graphics such as BOM of mold, weekly report with pictures, injection parameter report and dimension report to manage all of projects running process.

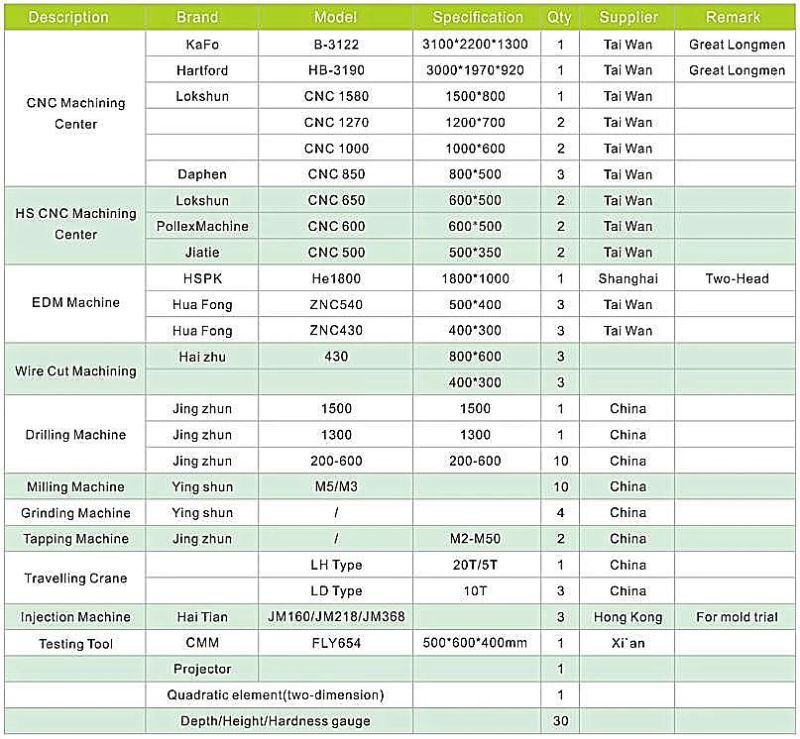

Machine List:

About Us:

Green Vitality has over 25 years of experience making high-quality injection moulds and producing high-quality plastic injection molded components. Our factory has passed ISO 9001:2015, ISO 14000 and TS16949 are also in our agenda. We also offer assembly and packaging services. This capacity ensures we can fulfill multiple high-volume orders quickly.

Our capabilities include:

- Prototyping

- Multi-cavity Mold

- Two-Shot Mold

- Insert molding

- Overmolding

- Mold maintenance and repair

- High-volume order production

- Finishing services (Ultrasonic Welding, Sonic Welding, Silk Screening,pad printing, Painting, in-mold decorating, labeling)

- Product assembly