CCM Continue Casting Copper Moulding Mould Tube for Billet

Henan Shengmiao Instrument Co., Ltd.- Mold Material:Metal Mold

- Function:High Temperature Resistance

- Material:Copper

- Application:Continue Casting Machine

- Type:Special Casting

- Certification:ISO, SGS

Base Info

- Specification:100*100*812-R4000

- Transport Package:Wooden Package

- Samples:Provided

- Size:Customized

- Advantage:High Casting Speed

- Feature:Optimum Binding Strength

- Shape:Square Copper Tubes

- Condition:New

- Customized:Customized

- Metal Color:Non-Ferrous Metal

- Warranty:6 Months

- Trademark:Shengmiao

- Origin:China

- HS Code:8454209000

- Production Capacity:50000,Month

Description

Basic Info.

Warranty 6 Months Metal Color Non-Ferrous Metal Customized Customized Condition New Shape Square Copper Tubes Feature Optimum Binding Strength Advantage High Casting Speed Size Customized Samples Provided Transport Package Wooden Package Specification 100*100*812-R4000 Trademark Shengmiao Origin China HS Code 8454209000 Production Capacity 50000/MonthProduct Description

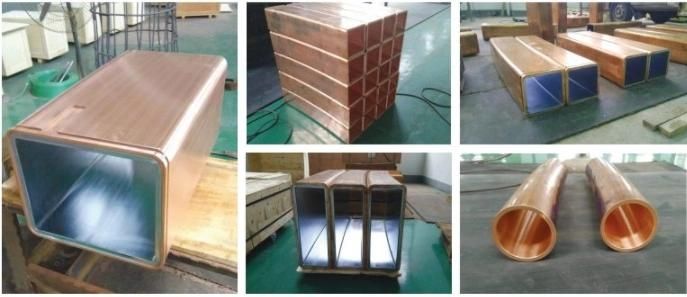

CCM Continue Casting Copper Moulding Mould Tube for BilletOur products including square copper mould tube, rectangular copper mould tube, round copper mould tube, beam blank copper mould tubes and other non-standard copper mould tubes. Products specification are as following:| Product Name | Size | Thickness | Length | Radius |

| Square Copper Tubes | 50x50-650x650 | 6-50 | 602-1100 | 3000-17000 Or straight |

| Round Copper Tubes | φ110-φ1500 | 10-50 | 602-900 | 5000-17000 Or straight |

| Rectangle Copper Tubes | (100-500)x650 | 6-50 | 602-1100 | 3000-17000 Or straight |

| Beam Blank Copper Mould Tubes | 535-150x120-70 | 12-50 | 700-1016 | 6000-14000 |

| Non-standard Copper Mould Tubes | 535-150x120-70 | 12-50 | 700-1016 | 6000-14000 |

Advantages of Ccm Copper Moulding Mould Tube for Billet :

• High casting speed

• Uniform shell growth

• No sticking

• Optimum billet quality

• Long service life

• Low cost

Ccm Copper Moulding Mould Tube for Billet Production Process:

MELTING & CASTING --- HOT EXTRUSION/FORGING --- COLD DRAWING --- TAPERING --- MACHINING --- ELECTROPLATING --- MACHINING AFTER ELECTROPLATING --- FINAL INSPECTION --- PACKING

Copper Mould Tube Coating

In order to increase the erosion resistance and service life the casting mould tubes, we always dedicated to research special coatings. The mould tubes can be coated with our different types of internal surface coating: Cr, Ni-Co, Ni-Fe, Ni-Co-Cr. The coating thickness recommended by us has been controlled in the best range.

We supply all kinds of Copper Mould Tubes of all sizes and dimensions, produced exactly as per the required drawing.

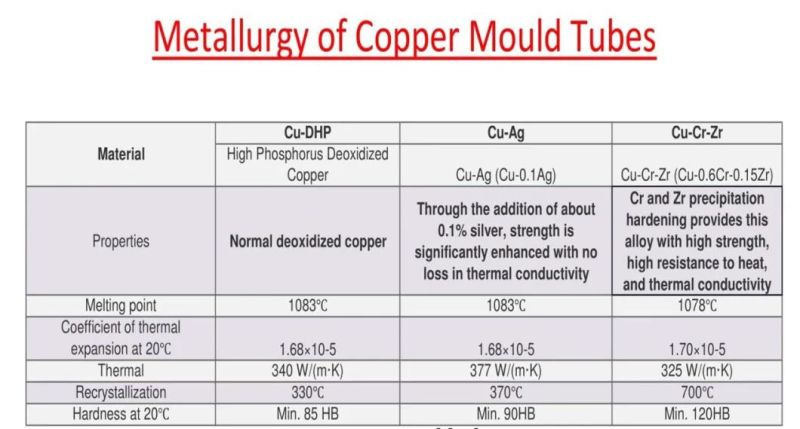

Raw Material of Copper Mould Tubes

To provide mould tubes with optimal physical and mechanical properties to customers' specifications, mould tube products are supplied of the following materials:

1. Cu-DHP: Normally used for mould tubes section size below 180x180mm and round tubes below Dia.150mm.

2. Cu-Ag: Normally used for mould tube section size above 180x180mm and round tubes above Dia.150mm

3. Cu-Cr-Zr: Normally used for beam blank mould tubes

These materials have different levels of hardness and thermal conductivities. We are highly experienced in choosing proper materials to meet the specific demands in heat resistance and thermal conductivities of customers' applications.

About Shengmiao

Henan Shengmiao Instrument Co., Ltd. is one of the China's leading supplier of copper mould tube and plate for continuous casting industry. At present, its cooperate headquarters locates in Zhengzhou, a vibrant national central city of China.

To enhance the core competitiveness, the company insists on researching cutting-edge technology and developing new material applied in copper alloy and metallurgy field. We always cooperate with many scientific research institutions. Based on some cooperation projects, we can find the best solution for customers, which optimize our products. Strong technical R & D abilities support us to meet the different demand of customers to the maximum extent. We attach great importance to technical innovations and manufacturing creations.

The company pays attention to develop agent and partner cooperation relationship. Since its foundation, it established strategic cooperation with agents to develop win-win partner relationship worldwide to provide a variety of high quality products to customers home and abroad; It has a vast inventory which will aid you in the quick deliveries, high quality and extremely competitive products. Our materials, technologies and products -- plus a worldwide network of partners -- all contribute to making Shengmiao a leading supplier of copper mould tube. For large-scale projects and special solutions in particular, we offer customers a one-stop shop. Our technological edge means that our solutions are consistently among the best in their field.

To ensure long-term customer satisfaction, we always make effort to provide technical support for copper mould over their whole life cycle. Our highly skilled staff know every detail and every single component. After all, they developed and designed it themselves. That is why the experts from Shengmiao are exactly the right choice when it comes to ensuring lasting reliable using of copper mould. Copper moulds from Shengmiao are being used worldwide. International teams and worldwide service centers guarantee immediate proximity to the customers, great flexibility, short response times and bundled competence for all-round customer support.

The advantages for the customer of the service provided by us are obvious:

- Increased productivity

- Improved product quality

- Reduced operating costs

TECHNICAL ASSURANCE

Our mould tubes and plates are made from the highest grade raw materials using pure metal.

Moulds are produced through advanced high-speed CNC machining centers, that can efficiently machine copper mould tubes and plates of virtually any size to precise specifications. The precision high-speed machining technology allows us to accurately and quickly machine the complex contours and profiles required by many designs while holding extremely tight tolerances.

Continuous product development, improved production processes in modern factories and extensive experiences in product design and manufacturing have combined to make us an international success.

Every phase of the mould tube producing system is highly monitored and closely controlled.

We provide strong after sales support through our team of engineers to ensure best performance for you.

Our mould tubes are known for their superior performance in even the most demanding applications.

Customer Visiting