Plastic Injection Moulds for Bird Feeder Parts

Green Vitality Industry Ltd.- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Medical Equipment, Hospital Use

- Process Combination Type:Single-Process Mode

- Plastic Material:PC

- Mould Cavity:Single Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Heat Treatment

Base Info

- Specification:As per request

- Transport Package:Ply Wood Box

- Manufacturing Experience:25 Years

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Mobile

- Design Software:AutoCAD

- Runner:Hot Runner

- Model NO.:GV-mold

- Trademark:GVI

- Origin:China

- HS Code:8480710090

- Production Capacity:500 Sets Per Year

Description

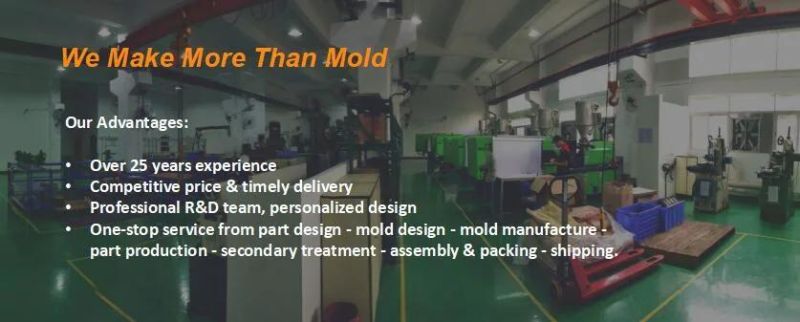

Company Profile:

Green Vitality Industry Co., Limited was founded in 1993.

With 25 years experience in custom tooling and injection molding, we have become a good mold maker in manufacturing all kinds of plastic injection molds and molding parts.

Product Show:

We serve a broad range of customers in the field of automotive industry, electronic and electrical appliances, concerning connector molding parts, auto parts, medical parts and other tooling, etc.

One-stop service:

Our one stop shop for designing and building molds, maintaining and running molds, and various secondary operations needed ensures customers are receiving the time and attention needed to get the best quality parts.

- New product development,

- Mold/structure design,

- Prototype fabrication,

- Plastic injection mold,

- Plastic molding parts...