Custom Design Multi Cavity Injection Moulding for Plastic Pots

Dongguan Howe Precision Mold Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:PP, PC, ABS, PE, HDPE, Pet, POM, PMMA, PA(GF), PBT

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Tech Polish, High Gloss, Texture, Printing

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Base Info

- Mould Precision:+ , - 0.01mm

- Steel Treatment:Heat Treatment, Nitriding, Chrome Plating

- Mold Life:500,000 Shots - 2,000,000 Shots

- Ejection System:Stripper Plate, Lifter, Push Bar, Ejection Pin, Et

- Mold Gate:Fan Gate, Sub Gate, Pinpoint Gate, Valve

- Hardness of Steel:46~56HRC

- Core and Cavity Material:DIN2312, 2738, 2344, 718h, S136h, 8407, Nak80, SKD

- Customized:Customized

- Standard:HASCO

- Certification:CE, ISO

- Installation:Semi Fixed

- Design Software:Ug, Autocad, PRO-E

- Runner:Cold Runner

- Model NO.:HW-201116-5

- Transport Package:Wooden Cases,Air,Sea

- Specification:According to customers′ drawings

- Trademark:OEM

- Origin:Dongguan, China

- HS Code:8480719090

- Production Capacity:300-400 Sets,Year

Description

Basic Info.

Model NO. HW-201116-5 Runner Cold Runner Design Software Ug, Autocad, PRO-E Installation Semi Fixed Certification CE, ISO Standard HASCO Customized Customized Core and Cavity Material DIN2312, 2738, 2344, 718h, S136h, 8407, Nak80, SKD Hardness of Steel 46~56HRC Mold Gate Fan Gate, Sub Gate, Pinpoint Gate, Valve Ejection System Stripper Plate, Lifter, Push Bar, Ejection Pin, Et Mold Life 500,000 Shots - 2,000,000 Shots Steel Treatment Heat Treatment, Nitriding, Chrome Plating Mould Precision + / - 0.01mm Transport Package Wooden Cases/Air/Sea Specification According to customers′ drawings Trademark OEM Origin Dongguan, China HS Code 8480719090 Production Capacity 300-400 Sets/YearProduct Description

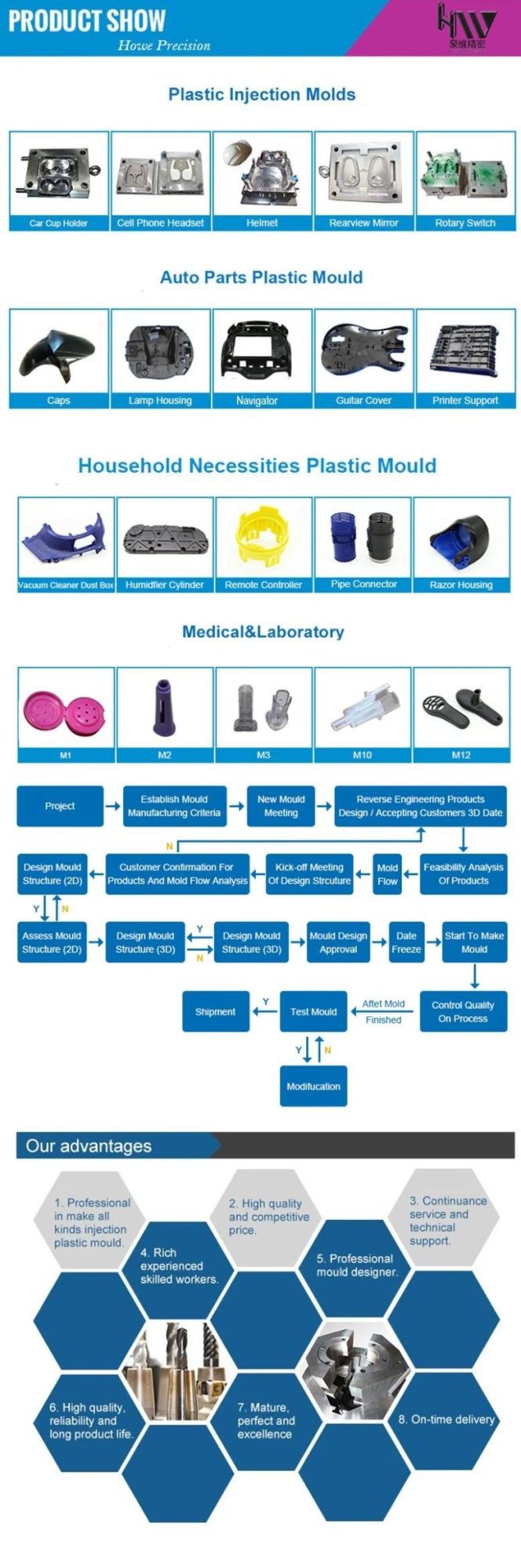

Portable Bonsai plants plastic pots custom design multi cavity injection mouldingHowe Mold is professional in the plastic injection mold, The injection mouldings parts include consumer goods, household appliance products (microwave oven, juicer, etc. ), electrical appliances (washing machine, air conditioner, refrigerator, television, etc. ), automotive parts (dashboards, inner decorating accessories, fender, bumper, etc. ), IT industry products (cell phones, computer, etc. ), office accessories (telephone, printer, etc. ) as well as other varieties of products. We look forward to participating in the success of your next project.

Mould Information:

| Injection Material | ABS, PP, PC, PP+GF, PA, PA+GF, PS, POM, PMMA, PC, etc. |

| Steel of Cavity&Core | Depends on Product, we help customer to choose the suitable material. Commonly used material are P20,NAK80,718,etc. |

| Steel of Mold Base | Depends on Product, we will help customer to choose the suitable material. Commonly used material is S50C. |

| Cavities | Customized |

| Hardness of Cavity & Core | Pre-Hardness Steel: HRC 32 ~ 36, Heat Treatment Steel: HRC 48~50° |

| Core pulling or Ejection system | Depends on the Product. Commonly used : Angel pin, oil cylinder, motor,stripping plate, ejector pin, etc. |

| Surface Finish | Depends on the product. Commonly used: Texture Hatching, EDM Hatching, Polishing, Diamond Polishing,etc. |

| Mold Life | Depends on the steel hardness and the plastic material |

| Runner | 1. Cold Runner, 2. Hot Runner. |

| Machine Center | CNC milling machine, CNC Lathing machine, EDM, NC milling & lathing machine, etc. |

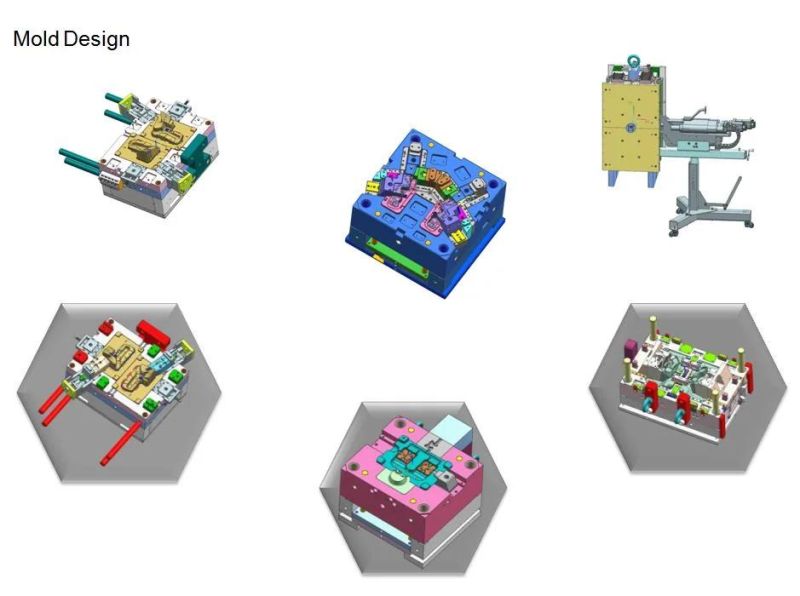

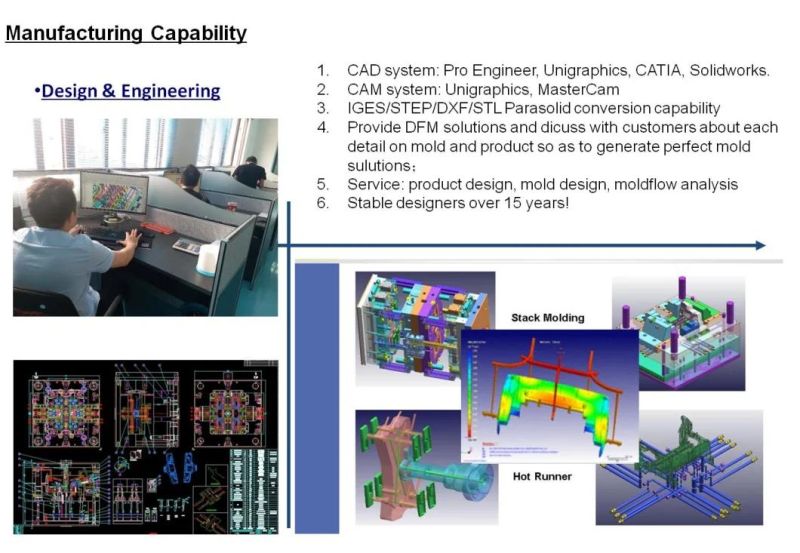

| R & D | We offer customers the drawings for products and mold design. Also we provide extra service such as Reversing Engineering Drawing, etc. We can work with 2D/3D drawings or with provided samples. |

| Production | Pilot Run Production and Molding Production. |

| Plastic Mold (Moulds) production process | Description |

| 1. 3d Design/Samples for quotation | According to 3D drawing or samples for quotation. |

| 2. Negotiations | Including the price of moulds, moulds sizes, material for cores & cavities, the weight of the product, part cost, payment, moulds lifetime, delivery, etc. |

| 3. Purchasing Order | After the customer confirming the mould design and quotation. |

| 4. Making mold | Confirm drawing, start to do DFM,mold flows and mold detail agreed with the customer, start production. |

| 5. Production schedule | Every week we will feedback to the customer mold progress(picture). |

| 6. sample shoot | We provide the moulds test samples for confirmation(about 10-15 pieces), then, get your signature sample, mass production. |

| 7. Package | Wooden case for moulds, cartons for parts, or as your requirements. |

| 8. Delivery | deliver goods by air or by sea. |

Company profile

Our team

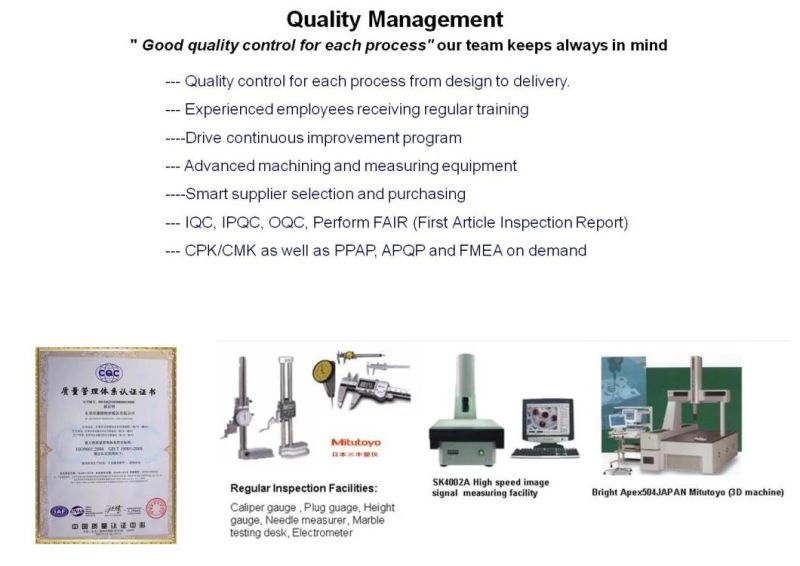

Quality Control

Our workshop

Our Services

Howe is a company specializing in the design and manufacture of high-quality plastic injection molds and injection molded parts for the international market and Have been engaged in the manufacturing sector since our inception.Is an OEM/ODM factory, customized your products to meet your needs is our advantage, We are managed by a group of professionals with many years of experience in mold design, molding technology and Quality control. We have developed an excellent understanding of the technical and quality requirements needed. We build tools to fit your expectations and match your quality standards.Our team of CAD designers will ensure that your imagination is incorporated into the actual product! If you want to create prototype or mass-produce in a very specific project, we can help you achieve your vision!Our products include :

1.Custom Plastic Injection Parts

2.Multi-cavity plastic parts

3.High Precision Molds

4.Insert & over molding

5.Double Shot Mold(2K mold)

6.Unscrewing Molding

7.Gas-assisted Molding

8.Die Casting Molding

9.Prototype plastic parts and Low cycle plastic parts molding

10Gas Assist molding

11.Elastomeric molding

12.IML & IMD part production

13.Thin wall plastic molding

14.High temperature molding

Packaging detail

Customer Visit

FAQ

Q: Can you accept OEM service?

A: Yes, we are warmly welcome OEM service. Just send your 2D&3D drawing or golden sample with quality demand (such as material, surface treatment, color, and package) to us.

Q: What is the drawing format you needed?

A: Prefer to STP, DXF for 2D&3D drawing, and PDF, AI, CDR, JPG for artwork design.

Q: What is your MOQ?

A: Usually our MOQ is 1000pcs, but we accept lower volume for your trial order.

Q: Can I get samples?

A: Sure, we usually provide a free store sample to you for quality checking. 1~2days can delivery. But there is a little sample fee that would be charged if you request your OEM samples, and it is refundable when your order is up to a certain quantity. 3~5days can delivery.

Q: How much is the freight charge?

A: To save money and time, we suggest to deliver by express for small quantity, and deliver by sea for large quantity. At the same time, we can get a big discount from a shipping company.

Q: Do you have a quality guarantee?

A: Yes. We have a QC department and 100% inspection before shipping, to ensure the CNC parts is NO visual defects, a traceable quality record for the product shipped from us, and if any fault is found, we commit to send a replacement at our cost, or any other more suitable solution depends on discussion with our customers.