Plastic Tube Holder Medical Equipment Parts

Xiamen Stick Industry Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:PC

- Mould Cavity:Single Cavity

- Surface Finish Process:Texture Surface

- Shaping Mode:Injection Mould

- Application:Electronic, Medical Equipment Parts

Base Info

- Transport Package:Standard Export Packing or as Per Request

- Mould Life:100, 000-1, 000, 000 Shots

- Mould Leadtime:3-6 Weeks

- Certificate:FDA, RoHS

- Finish:Color Painting, Texture, Silk Printing

- Material Applied:ABS, PC, PS, PP, PVC, TPR, TPU, TPE, etc

- Standard:HASCO

- Customized:Customized

- Certification:CE, ISO

- Installation:Fixed

- Design Software:Pro-E

- Model NO.:STK-PLM0008

- Specification:ISO9001: 2000

- Trademark:Customized or STK

- Origin:China

- HS Code:3926909090

- Production Capacity:50, 000PCS,Mouth

Description

Plastic Materials Applies

Plastic Injection Solution:

* Precision Injection Molding: From design consultancy & prototype tooling to high-volume world-class production

* Parts are widely used: Industrial, Automotive, Electronics & Medical

Technical Skills - Development, Design Skills

* Design Consultation & Assistance

* Pro/E, CAD/CAM/CAE including Solid Works(TM) and mold flow analysis

* Material Selection Assistance

* Quick turn-around prototype support

* Secondary Operations including machining, welding & assembly

Molding - High Precision, High Concern

* Plastic Decorating: In-Mold Decorating (in-mold labeling), pad printing & hot stamping

* 40 Molding machines from 80TONS to 1400TONS

* High precision molding from medical to fiber optics components

Secondary Operations - Value Added Service

* Pad Printing

* Sonic Welding

* Assembly & Packaging

Plastic Injection Molding Workshop

Plastic Injection Equipment List

QC Control Facility

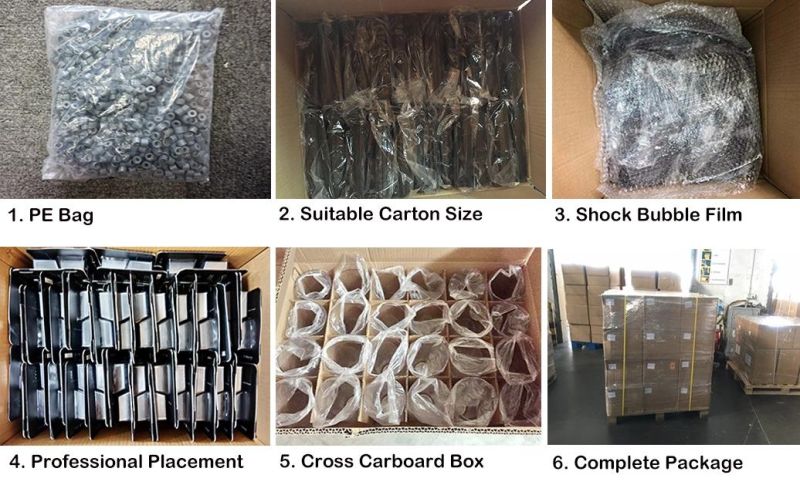

Packing & Delivery

FAQ:

Q: Are you trading company or manufacturer ?

A: We are factory. We are experienced manufcturer, have our own factory and warehouse.Q: What do we need if you want a quote?

A: Please kindly send us your 2D & 3D drawing of your product. The need the detail specifications as follows :1. Material

2. Surface treatment

3. Estimated production volume

Q:How doe the payment process work ?

A: Our preferntial payment term is T/T Mould Tooling : 50% down payment, 50% balance against the sample approval.

Mass Production: 50% down payment , 50% against the B/L copy .

Q: How do I know about the production ?

A: We will double confirm your requirements and send you the samples before the mass production . During the mass production , we will keep you informed of any progress.Besides, we will do 100% quality inspection

before shipment