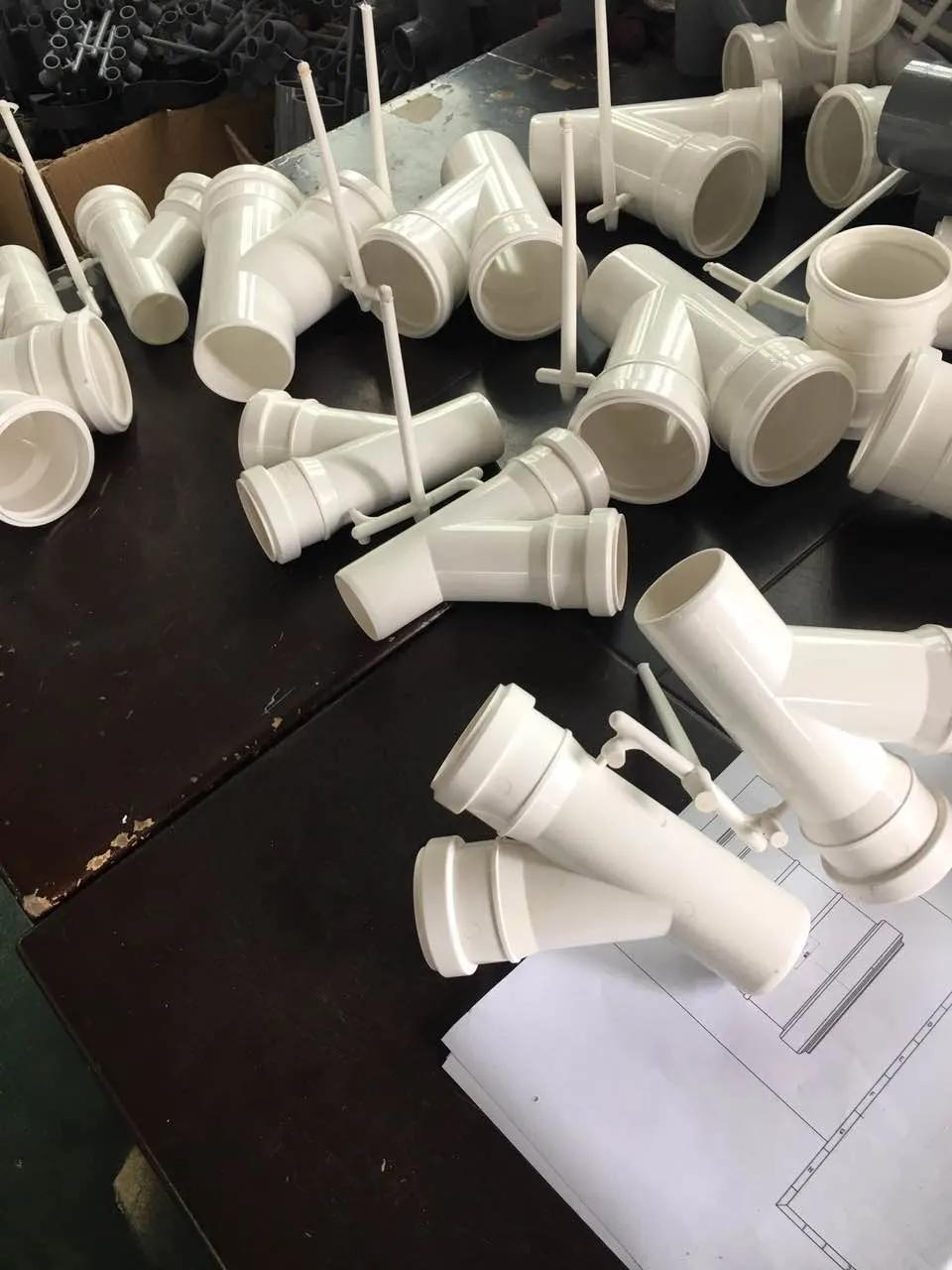

Plastic Injection PVC Pipe Fitting Mould

Taizhou Huangyan Yongsheng Mould Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:PVC

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Household Appliances, Commodity, Electronic, Home Use

Base Info

- Specification:To meet customer needs

- Transport Package:Wooden Case

- Surface Treatment:Polish, Etched...Ect.

- Process:CNC, High Speed Carve, EDM, Wire Cut, Drill, Lathe

- Design Softare Ware:Ug, PRO,E, Autocad, Mouldflow...Ect.

- Gate Type:Edge Gte

- Name:Plastic Injection PVC Pipe Fitting Mould

- Customized:Customized

- Installation:Fixed

- Design Software:UG

- Runner:Cold Runner

- Model NO.:YS180417

- Trademark:YS

- Origin:China

- HS Code:8480719090

- Production Capacity:90 Sets PVC Pipe Fitting Mould Per Month

Description

Basic Info.

Model NO. YS180417 Runner Cold Runner Design Software UG Installation Fixed Customized Customized Name Plastic Injection PVC Pipe Fitting Mould Gate Type Edge Gte Design Softare Ware Ug, PRO/E, Autocad, Mouldflow...Ect. Process CNC, High Speed Carve, EDM, Wire Cut, Drill, Lathe Surface Treatment Polish, Etched...Ect. Transport Package Wooden Case Specification To meet customer needs Trademark YS Origin China HS Code 8480719090 Production Capacity 90 Sets PVC Pipe Fitting Mould Per MonthProduct Description

MOULD DESCRIPTIONCavity: 1-8

Mould base material: 2316, 718, P20, #45

Core&Cavity material : 2316, 718, P20, #45

Runner: Cold

Life time: 1M

Quick T1 time: 40 days

Package: Wooden case

MOULD MANUFACTURE PROCESS

Grinding→ Fly-cutter → CNC Milling→ Drilling→ Lathe→ Boring lathe→ Electric pulse → Fine fly-cutter→ Polish→ Electroplate→ Assemble

Business Procedure

| 1. | Quoting Price based on customer's request. |

| 2. | Signing the sales contract/ Stamping Proforma Invoice. |

| 3. | Starting the 2D/3D drawing of the mould. |

| 4. | Sending customer mold 3D/2D design drawing for confirmation. |

| 5. | Starting Manufacturing after design approved by customer. |

| 6. | Testing mold with noticing customer. |

| 7. | Delivering the samples for customer's approval. |

| 8. | Doing final polish or treatment for the mold after samples approved. |

| 9. | Shipment. |

AFTER-SALE SERVICE

Any mould problem, we will provide free maintenance service

Why Choose Us?(Advantages)

1.We specialized in manufacturing plastic injection mould for over 40 years and

received a high evaluation and recognition of our customers .

2. We have a high-level designer team and we adopt advanced machine as

CNCDMGEDMCMM.

3. During mold manufacturing, we keep customer updated with our ONLINE

TRACKING SYSTEM, which shows mold process clearly to customer from

Steel purchasing till Mold testing.

4. We have strict quality control system.

5. We do not delay any project.