Custom Plastic Injection Auto Mold for Dash Board Parts

Dongguan Shienji Technology Co., Ltd.- Plastic Material:PC,ABS

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Warranty:1 Year

- Process Combination Type:Single-Process Mode

Base Info

- Specification:As per drawing

- Transport Package:Custom

- After-sales Service:1 Year

- Customized:Customized

- Standard:HASCO

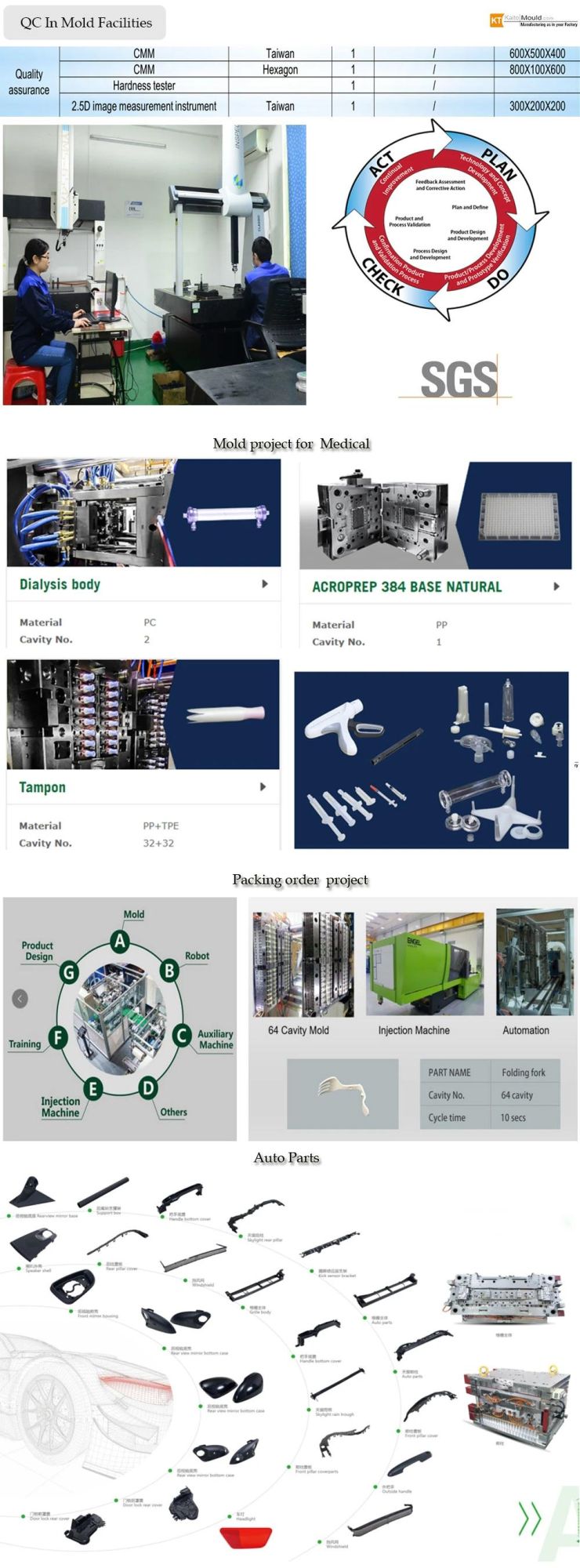

- Certification:TS16949, CE, ISO, FDA

- Installation:Fixed

- Design Software:UG

- Runner:Cold Runner

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Model NO.:PIM

- Trademark:OEM,ODM

- Origin:Dongguan

- HS Code:8480719090

- Production Capacity:50 Sets,Month Plastic Injection Mold

Description

| Item | Custom Plastic Injection Mold/Mould/Tooling |

| Application | Automotive, Household Appliances,Consumer Products Lawn & Garden,Electronics Medical Technologies, Power Generation Power Tools, Returnable Packaging |

| Customized | Accept customized products, the mold building will according to the part design from you. |

| Steel Material | P20, 1.2343, 1.2344, 1.2311, 1.2312, 1.2738, H13, NAK80, 738HH, S136, etc |

| Products Material | PA, PA6, PA6+GF, ABS, POM, PC, PP, Nylon, PET, TPE, TPU, HDPE Injection Mold, etc |

| Cavity | Single-cavity, Multi-cavity |

| Runner system | Hot runner, Cold runner |

| Payment Terms | T/T 50% deposit with PO, 40% after receiving T1 samples, 10% after samples approval and before shipment. |

Different injection mold type:

1: Two/Three plate mold

2: Unscrewing mold

3: Cold runner mold

4: Hot runner mold

5: Insulated runner mold

6: Gas assist injection mold

7: Insert mold

8: 2K mold

9: Overmolding mold

10: IML / IMD mold

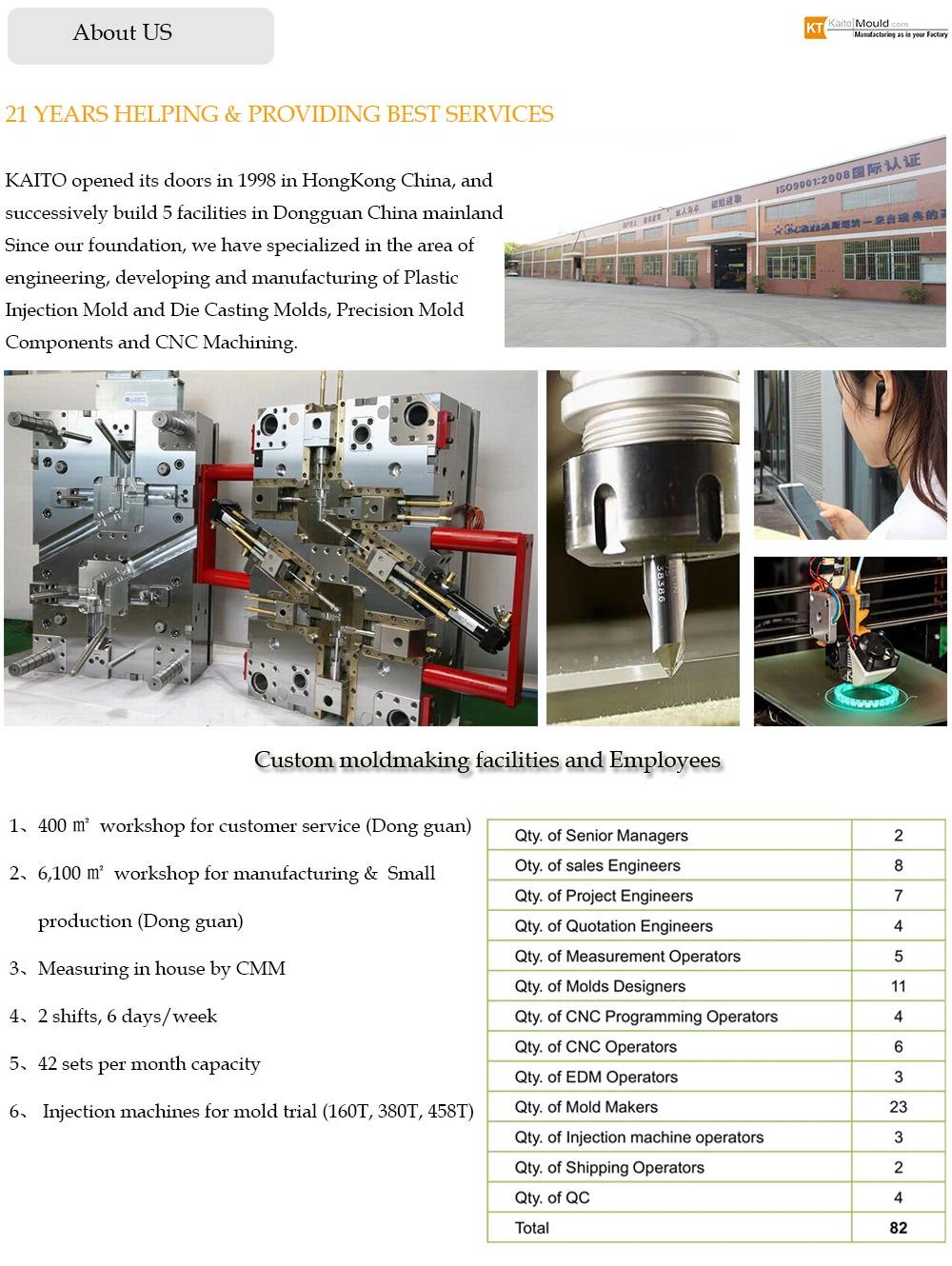

Customized mold made by Kaito:

automotive mold, auto dashboard mold, auto interior parts, auto door handle mold, central control board mold, air conditioner vent mold, household appliances mold, medical equipment mold, oximeter, chips mold, tray mold, storage box mold, toilet cover mold , etc

Raw material we usually use:ABS mold, PP mold, PA mold, PE mold, PC mold, TPU mold, TPE mold, POM mold, Nylon mold, PA6+GF mold, PA6 mold, PET mold, HDPE mold, etc

Provide low cost and short lead time.

Provide low cost and short lead time.Find best solution according to technical requirements and budget constraints.

Review technical issue according to your specificaiton.

Manage and report the process all though project process.

Assess capacity prior to committing the project schedule.

Regular vendor process review to promote supply chain management.

Experience mold engineers provide after sales technical support.

Very competitive price.