Plastic Protection Agnle for Busduct System

Suzhou Kiande Electric Co., Ltd.- Plastic Material:PA66

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Warranty:1 Year

- Process Combination Type:Single-Process Mode

Base Info

- Transport Package:Carton

- Usage:Used on Conductor to Protect The Mylar Film

- Customized:Customized

- Standard:HASCO

- Certification:ISO

- Installation:Fixed

- Design Software:AutoCAD

- Runner:Hot Runner

- Application:Electricity-Busbar Trunking System

- Model NO.:KDEQ-03-348

- Specification:thickness 5mm, 6mm, 7mm

- Trademark:Kiande

- Origin:China

- HS Code:8547200000

- Production Capacity:500000pieces Per Month

Description

Basic Info.

Model NO. KDEQ-03-348 Application Electricity-Busbar Trunking System Runner Hot Runner Design Software AutoCAD Installation Fixed Certification ISO Standard HASCO Customized Customized Usage Used on Conductor to Protect The Mylar Film Transport Package Carton Specification thickness 5mm, 6mm, 7mm Trademark Kiande Origin China HS Code 8547200000 Production Capacity 500000pieces Per MonthProduct Description

Protection angle for busbar conductorFeatures:

1. Used to protect the polyester film when wrapping the copper & aluminum bar conductor

2. Material: PA66

3. Insulation, flame retardant, withstand voltage

We are the company specialized in busbar machine.Busbar machine means busbar production machine or busbar processing machine including mylar sleeve forming machine, busbar assembly machine, busbar riveting machine, busbar testing & inspection machine, busbar packing machine and busbar conveying machine. If you want to know how we use the machine to assemble the busbar, please kindly get the referenced pictures as below.

Step 1 Prepare all busbar finished components

Step 2 Use related busbar machines to process the busbar

Busbar machine copper processing

Need Kiande's busbar gas-hydraulic copper bar punching machine(This is one-time punching forming. In the market, some busbar manufacturer buys three-in-one busbar machine to bend and punch copper or aluminum bar. As the bar experiences many procedures, the accuracy is not good which will cause the phase distance too small to cause the short circuit.)

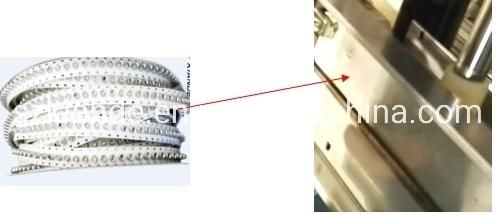

Busbar machine mylar sleeve processing machine polyester film forming machine

Need Kiande's mylar/polyester film forming machine. In the market, some busbar manufacturer requests workers to wrap the bar manually. Different workers have different workmanship. If employer meets the inexperienced workers, the wrapping part will have some gaps which will cause the short circuit.

Busbar machine busbar accessory 3M insulation film Conductor(Copper bar/Aluminum bar) end wrapping

Busbar machine busbar accessory Aluminum profile capped casting capped end

Busbar machine Busbar riveting machine

Busbar machine busbar inspection machine busbar testing machine

Busbar machine busbar packing machine busbar packaging machine

Busbar machine busbar accessory rivet the rivet is to connect the profiles instead of bolts more stable and strengthen

Busbar machine busbar accessory joint isolator Busbar joint pack

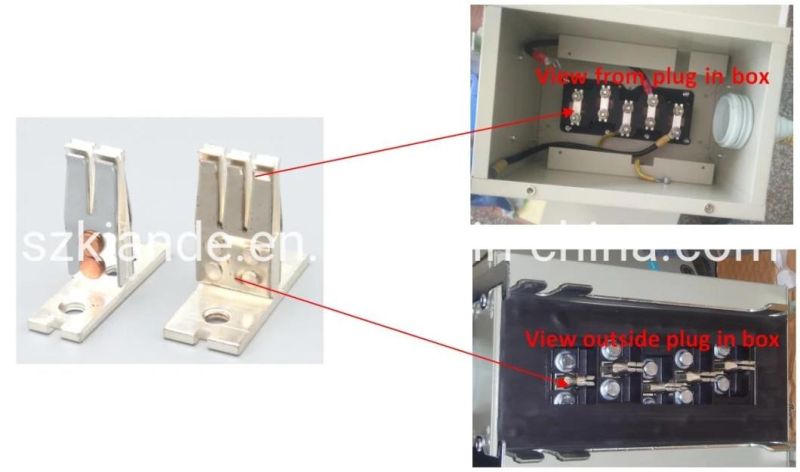

Plug-in contacts clips Busbar accessory Plug-in earth contact clip