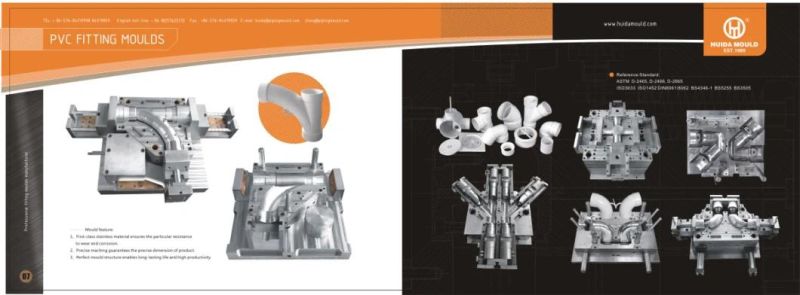

PVC Collapsible Elbow 45 Pipe Fitting Mould

Taizhou Huangyan Huida Plastic Machinery Co., Ltd.- Plastic Material:PVC

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Household Appliances

- Design Software:UG

Base Info

- Specification:1,2" to 12"

- Transport Package:Wooden

- Export Percentage:95%

- Gate:Direct,Point,Submarine,Rectangle,Side,Tunnel

- Surface Treatment:Polish. Etched. Texture

- Mould Base:European Standard

- Mould Material:P20,718,738,Nak80,S136

- Mould Life:300000-1000000shots

- Cooling System:in Core Baffle and in Cavity Plate Chain Drilling

- Customized:Customized

- Certification:ISO

- Installation:Mobile

- Model NO.:PVC

- Trademark:HUIDA MOULD

- Origin:Zhejiang, China

- HS Code:3323963208

- Production Capacity:2000sets,Year

Description

Basic Info.

Model NO. PVC Installation Mobile Certification ISO Customized Customized Cooling System in Core Baffle and in Cavity Plate Chain Drilling Mould Life 300000-1000000shots Mould Material P20/718/738/Nak80/S136 Mould Base European Standard Surface Treatment Polish. Etched. Texture Gate Direct/Point/Submarine/Rectangle/Side/Tunnel Export Percentage 95% Transport Package Wooden Specification 1/2" to 12" Trademark HUIDA MOULD Origin Zhejiang, China HS Code 3323963208 Production Capacity 2000sets/YearProduct Description

General information

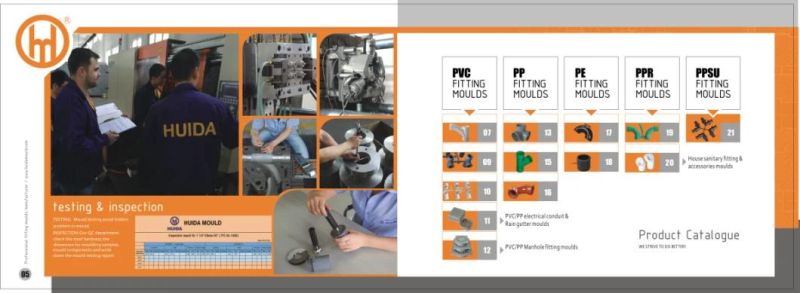

| Plastic material | ABS/PP/PVC/PPSU/PE/CPVC |

| Core&Cavity Steel | P20,718H,,1.2344,1.2316 S136 H13 |

| Steel hardness: | HRC35-38 HRC45-48 |

| Mould Standard | DME |

| Cavity Number | Single/ Multi |

| Injection System | point gate / side gate / direct gate |

| Ejector System | Machican / air push |

| Cycle Time | According to the size |

| Tooling lead time | 45-60 days |

| Mould life | 300,000 -1000000times |

| Suface Finish | Polishing, Chrome, Stria, Frosted, etc. |

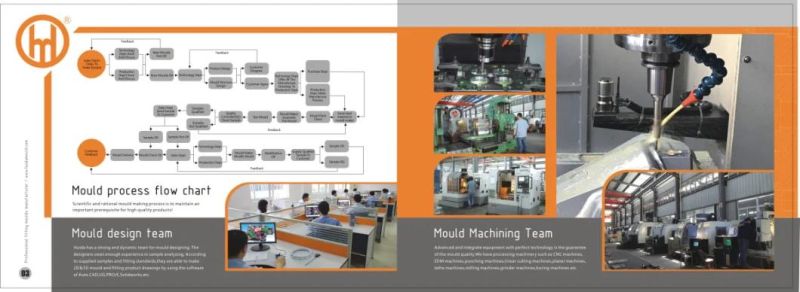

Taizhou Huangyan Huida Plastic Machinery Co.,Ltd was established in 1989.We have been devoting to the pipe fitting mould's design and manufacture for more than30 years.We have particular experience in producing customized plastic pipe fittings.Including sanitary and drainage system,potable water supply,roof drains.irragation,and gas supply with material of PVC,PPR,PP, HDPE,ABS,PPSU etc.Therefore,we have won the trust from over 200 customers in more than 60 countries around the world.

FAQ:

Q1:Which kind information need for plastic mold quotation?

A:1.Sample photo with size or 2D/3D design

2.Mould steel type

3.Cavity quantity

4.Life service

5.Runner type

Q2:What is your terms of packing?

A2:Generally, we pack our goods in wooden case or as per required. Mould surface will be painted. Use anti-rust oil inside the mold, plastic film outside, and use standard export wooden case for seaworthy shipping. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.Q3:How do you make our business long-term and good relationship?

A3 1. We keep good quality and competitive price to ensure our customersbenefit ;

2. We respect every customer as our friend and we sincerely do business

and make friends with them, no matter where they come from.

Our Services

| 1. R& D | We support customer R& D. |

| 2. Quotation Making | Mould Quotation will be finished in one day based on information given. |

| 3. Negotiation | The quality, price, material, delivery time, payment ect. |

| 4. Mould Design | 3-7 days for mould and product 3D drawing design |

| 5. Mould | Make moulds based on customers' requirements. Mould design sent to customer for approval first. Mould will be usually finished in 60 days |

| 6. Mould Testing | When moulds are finished, we will test the mould to check whether it meets customers' needs. And we will send samples for reference. |

| 7. Sample | If the first sample comes out do not satisfy customers, we will modify the mould until meeting customers' satisfaction. |

| 8. Delivery | Deliver by sea or by train for pipe fitting mould, according to customers' requirement. |