Yk20 16*36*66mm 15% Co Tungsten Carbide Mining Inserts

Zhuzhou Up Cemented Carbide Co., Ltd.- Technics:Forming Die

- Processing Method:Forming Mould

- Material:Tungsten Carbide

- Application:Household Appliances, Electronic, Hardware, Car, Commodity, Home Use

- Process Combination:Progressive Die

- Manufacturing Technology:Automation Technology

Base Info

- Transport Package:25kg. Carton

- T.R.S:3000MPa

- Surface:Rough Grinding 6 Sides

- Density:14.0g,cm3

- Hardness:87.0hra

- Wc:85%

- Co:15%

- Parts Detection Method:Geometric Detection

- Milling Speed:High Speed

- Mold Cavity Technology:The Traditional Forming Electrode Machining

- Driving Motor Type:Permanent Magnet

- Model NO.:YK20 16*36*66mm

- Specification:YG15

- Trademark:ZZUP

- Origin:Zhuzhou, Hunan, China

- HS Code:820900100

- Production Capacity:10000000PCS,Month

Description

Basic Info.

Model NO. YK20 16*36*66mm Driving Motor Type Permanent Magnet Mold Cavity Technology The Traditional Forming Electrode Machining Milling Speed High Speed Parts Detection Method Geometric Detection Co 15% Wc 85% Hardness 87.0hra Density 14.0g/cm3 T.R.S 3000MPa Surface Rough Grinding 6 Sides Transport Package 25kg. Carton Specification YG15 Trademark ZZUP Origin Zhuzhou, Hunan, China HS Code 820900100 Production Capacity 10000000PCS/MonthProduct Description

YK20 16*36*66mm 15% Co Tungsten Carbide mining insertsYK20 16*36*66mm 15% Co Tungsten Carbide mining inserts

Specifications

1. Grade: YK20 10% Co,90% WC,coarse grain sizes

2. YG8,YG6,YG10,YG15,YG20,YG25,YL10.2,YS2T,YG6X etc all kinds of grades for your choose.

3. Can product customize sizes and shape.

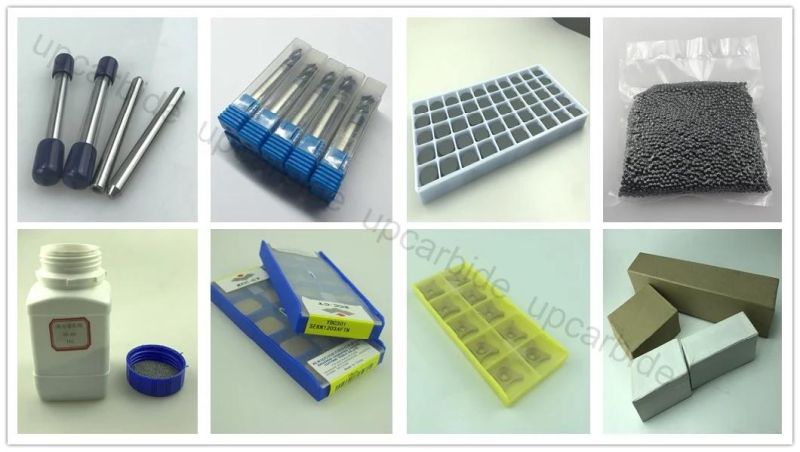

Products Show

grades choosing

| Grade | Density g/cm3 | Hardnes HRA | T.R.S Mpa | Performance&application recommended |

| YG6A | 14.85 | 92.5 | 2000 | Fine grain alloy,good wear resistance.it is suitable for manufacturing forming cutter,wear-resistant parts etc. |

| YG8 | 14.7 | 89.8 | 2800 | High bending strength,wear resistance lower than YG6A, suitable for manufacturing cutter ,wear-resistant parts etc. |

| YG11 | 14.4 | 88.5 | 2900 | High bending strength,wear resistance lower than YG6A, suitable for manufacturing cutter ,wear-resistant parts etc. |

| YG15 | 14.0 | 87.0 | 3000 | Suitable for manufacturing punching dies, wear-resistant parts. |

| YG20 | 13.5 | 85.5 | 2800 | High bending strength,suitable for manufacturing progressive dies and other punching dies. |

| YG25 | 13.1 | 81.5 | 2950 | High bending strength,wear resistance lower than YM6A, suitable for manufacturing cutter ,wear-resistant parts etc. |

| YS2T | 14.25 | 92.0 | 2500 | Fine grain alloy, with high wear resistance, bending strength, bonding resistance and thermal strength. it is suitable for machining refractory alloys,stainless steel, high manganese steel, etc. |

Other grades and sizes can be offered as per customers' requirements

Size choosing

| L(mm) | W(mm) | H(mm) | W(mm) | T(mm) | L(mm) | |

| 800 | 800 | 10~80 | 100 | 100 | 6~80 | |

| 600 | 600 | 10~80 | 100 | 50 | 6~80 | |

| 300 | 200 | 10~80 | 100 | 45 | 6~80 | |

| 200 | 200 | 10~80 | 80 | 55 | 6~80 | |

| 200 | 20 | 10~80 | 80 | 40 | 6~80 | |

| 150 | 150 | 6~80 | 70 | 35 | 6~80 | |

| 150 | 130 | 6~80 | 45 | 25 | 6~80 | |

| 150 | 100 | 6~80 | 35 | 19 | 6~80 | |

| 150 | 80 | 6~80 | 20 | 20 | 6~80 | |

| 120 | 120 | 6~80 | 18 | 12 | 6~80 | |

| 105 | 105 | 6~80 | .... | .... | .... |

2. Before delivery to you,all plates were detected by no damage ultrasonice,Keeping the plates all are no blister,no pore,high density & strength,impact resistance and long working life. 3.We can rough grinding and grinding the board surfaces.

Packing details

Shipping ways

Production process

Contact details