OEM/ODM Hot Selling Plastic Part Injection Mould

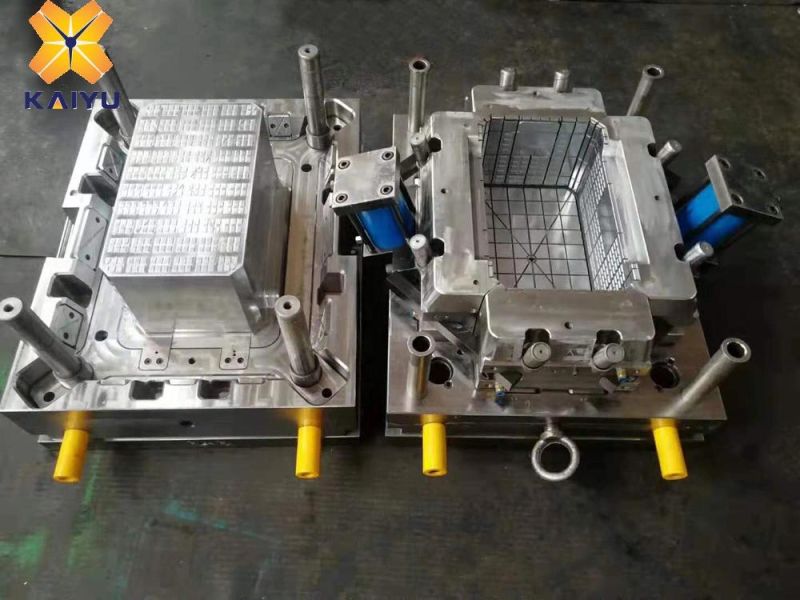

Taizhou Kaiyu Mould Co., Ltd.- Process Combination Type:Compound Die

- Plastic Material:PP

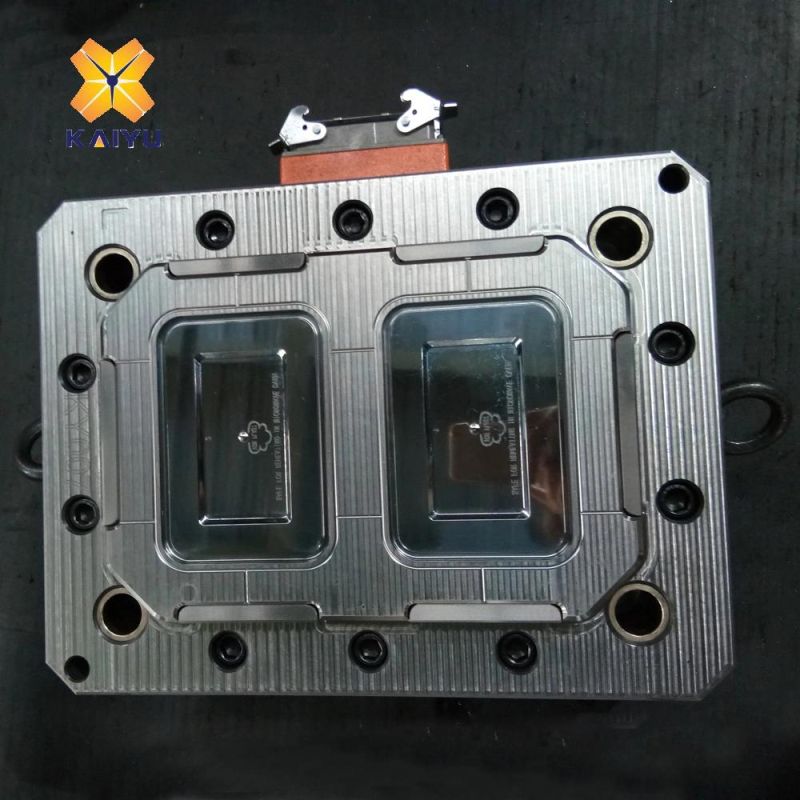

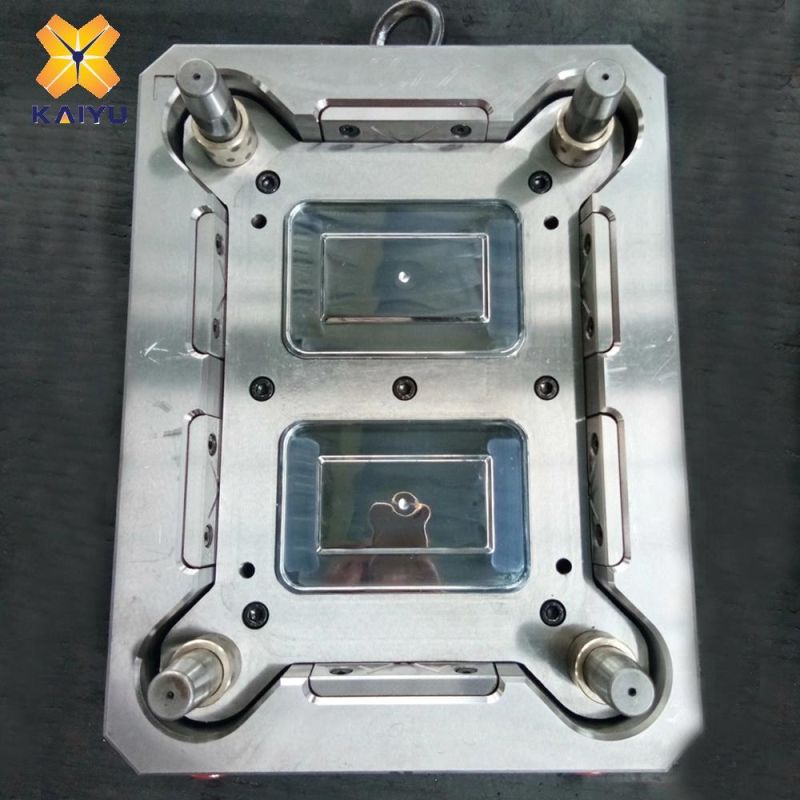

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Household Appliances, Commodity, Home Use

Base Info

- Specification:50, 100, 150, 200, 300, 400, 50, , etc

- Transport Package:Wooden Case

- Customized:Customized

- Standard:HASCO

- Certification:CE, ISO

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Model NO.:standard

- Trademark:KY Mould

- Origin:Taizhou

- HS Code:8480710090

- Production Capacity:5 Millions

Description

· Qualified steel with high hardness

· Nice polish with high brightness

· Nice machining with high precision

· Customized designs are accepted

· One-year after-sale service for free

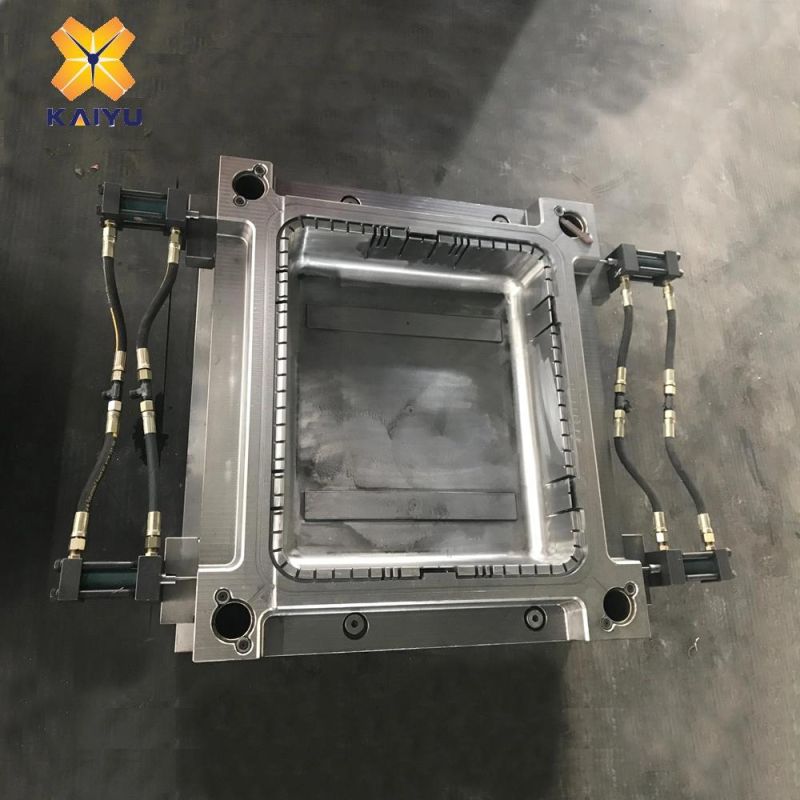

Mould Feature

1. Short cycle time and high efficiency in production.

2. Each cavity and core have independent cooling system, shortening production cycle time.

3. Rational mould design to extend mold life .

4. Mirror hand polishing to create added-value.

4. Precision Machining to ensure high production efficiency & fine parting line effect.

5. Skilled Language in communication and experienced in international standard.

package :

General FAQ

1.How long is the lead-time for mold?

It all depends on the mold's size and complexity. Normally, the lead time is 55-65days.

If the molds are very simple and not big size, we can work out within 50 days.

.

2.What's your after sales

For any products quality problems, we will replace at our expense. However, we will need to establish a clear quality inspection criteria at the beginning stage of the project.

We also have an CRM system to keep work history with all customers.

3.Can you do post production?

Some customers in addition to plastic injection require post processing, assembly of their products and packaging.

We have done this numerous times and have the facility and staff ready for these processes. You are welcome to inquire about post production if you need it. Or send us a quote request for any part you need. We will be happy to assist you with the quote or any technical, packaging, post processing or shipping inquiry

4..What's design software do you use for drawing making ?

UG, Pro-E, Master cam, Solid works, 3D max, AutoCAD, CAM.

Drawing format( 2D file- dwg, dxf/pdf, jpg), 3 D model format( igs, x_t, prt)

Mobile : 0086 152 58589130