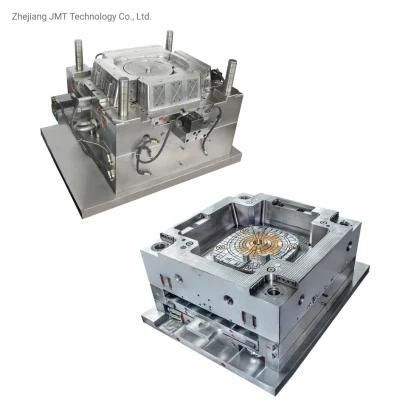

Washing Machine Home Appliance Plastic Injection Mould

Zhejiang JMT Technology Co., Ltd.- Plastic Material:PP

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Warranty:1year

- Process Combination Type:Single-Process Mode

Base Info

- Transport Package:Wooden Case

- Huangyan:Jmt -Technology

- After-sales Service:1year

- Customized:Customized

- Standard:HASCO

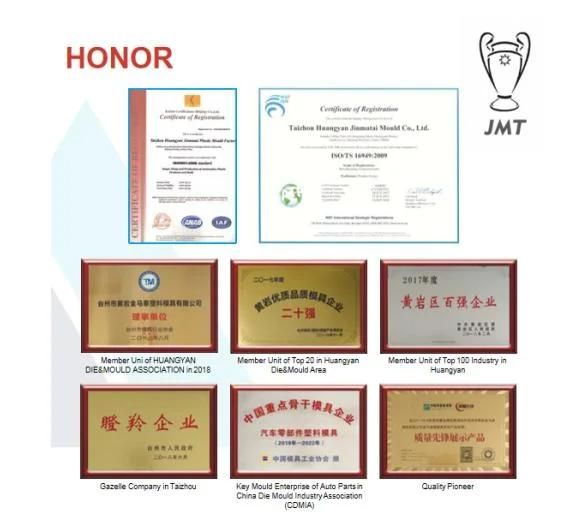

- Certification:TS16949, ISO

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Application:Home Use

- Model NO.:JMT2021396

- Trademark:JMT Technology

- Origin:China, Zhejiang, Taizhou

- HS Code:8480710000

- Production Capacity:650 Set,Year

Description

Basic Info.

Model NO. JMT2021396 Application Home Use Runner Hot Runner Design Software UG Installation Fixed Certification TS16949, ISO Standard HASCO Customized Customized After-sales Service 1year Huangyan Jmt -Technology Transport Package Wooden Case Trademark JMT Technology Origin China, Zhejiang, Taizhou HS Code 8480710000 Production Capacity 650 Set/YearProduct Description

Mould Name:washing machine parts plastic injection mould

Mould Steel:718HH, 738H, 2738H, H13, 2344, NAK80, NIMAX, 2316, S136 and so on.

Mould Base: C50, LKM, HASCO

Cavities :single cavities

Mould Spare Parts: DME, HSCO, MISUMI

Hot runner brand: YUDO, MOULD-MASTERS, DME, HASCO, SYNVENTIVE: UG

Locating Ring: Ø90,Ø100,Ø110,Ø120,Ø125,Ø150,Ø160

Mould Ejecting System: ejector pin,ejector block,stripper plate,air vavle,hydro-cylinder and so on

Sprue Bushing: Sprue arc:generally use FLAT and R15.5.minimum opening of the sprue arc:;Ø3.5mm.

Technology

1) Mould structure design

Professional designers provide you with reasonably designed mould to shorten cycle hours.

Reducing unnecessary procedure improves efficiency.

2) Mould cooling system

According to the structural characteristics of the product and the appearance of the product , We design a reasonable form of gate for mould, such as a large gate, hidden gate, fan gate, needle gate, pin point gate etc., a reasonable channel of runner design make mold temperature balance in the shortest time to improve mould precision and productivity.

3) Accessory for mould

Slide, guide pin, guide sleeve, lifter blocks and so on are taken by wear-resistant standard parts, to ensure the mould life.

4) Deal with mould

Quenching the mold, heat treatment to improve the hardness, then Nitriding temperature is lower , the mold will no longer need to quench mold with high surface hardness and wear res

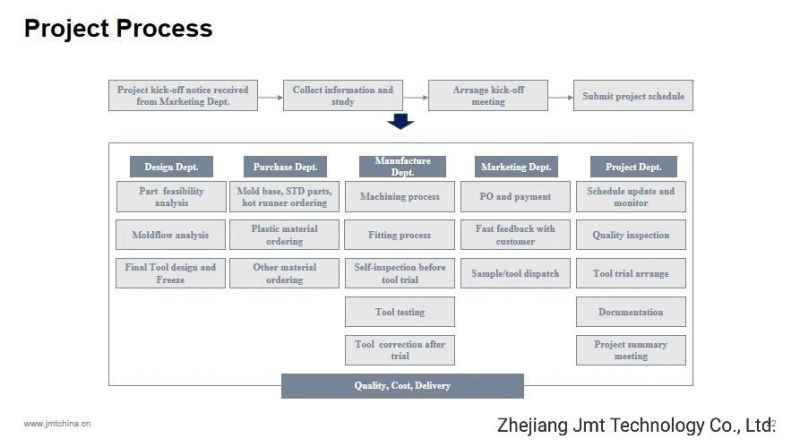

Zhejiang JMT Technology Co.,Ltd specializes in designing and making auto parts, home appliance, kids electric car and household moulds. From 2005 until today, JMT Mould has had many great achievements in plastic mould development and manufacturing. Today, JMT Mould has over two hundred workers, including a mold design team of over 42 engineers.

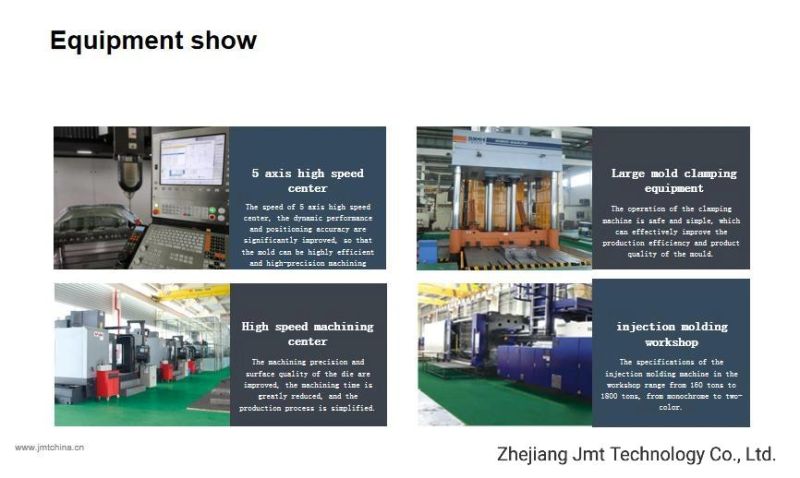

JMT Mould has organized their facility for efficiency using the latest principles of lean manufacturing. Their capabilities now include prototyping, an injection workshop and a state of the art QC lab. To help realizing the benefits of consistent quality systems and business practices, JMT Mould invested the time and effort to be awarded the ISO/TS 16949: 2009&tISO9001-2015 Quality Certification.

JMT Mould has grown into a superior mold manufacturer with a strong engineering team. Engineering work includes not only mold designs, but also mold feasibility, mold flow, product design expertise and prototyping services. These allow the most efficient mold strategies to be developed for our customers.

We have developed great relationships with customers such as VALEO, MAHLE GROUP, GOODBABY GROUP, by always providing excellent service. We are proud of our culture of continuous improvement and welcome all customers and potential customers to visit our factory anytime.

Q1:How do you need to quote?

We can quote a rough price with picture, but to get an accurate price, please offer the following

information:

1. 2D and 3D (format:CAD/PDF/DWG/DXF/DXW/IGES/STEP etc.)

2.Material

3.Quantity needed

4.Surface treatment

5.Any special pacaking or other requirements

Q2:What's the MOQ?

We can accept low quantity.

Q3:Can I get a sample for check?

Yes, just need sample cost and shipment cost,we will return it back in mass production.

Q4:Can you design product for me if I only have a rough concept ?

Yes! We can also offer design service as long as you tell us all your requires.

Q5:What's the leading time?

It depends on quantity.Generally 5-20 days after order confirmation..