Plastik Molding in Moulding for Baby Use Tooling

ZHEJIANG MELEE MOULD CO., LTD.- Plastic Material:PE

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Commodity

- Runner:Cold Runner

Base Info

- Transport Package:Wooden Case

- T1 Lead Time:30days

- Payment:50%and 50%

- Shipment:by Sea or by Air

- Size:30mm

- Customized:Customized

- Standard:DME

- Installation:Manual Installation

- Design Software:UG

- Model NO.:Melee mould-703

- Specification:SGS

- Trademark:MELEEMOULD

- Origin:Huangyan, Taizhou

- HS Code:8480719090

- Production Capacity:350sets ,Year

Description

Basic Info.

Model NO. Melee mould-703 Design Software UG Installation Manual Installation Standard DME Customized Customized Size 30mm Shipment by Sea or by Air Payment 50%and 50% T1 Lead Time 30days Transport Package Wooden Case Specification SGS Trademark MELEEMOULD Origin Huangyan, Taizhou HS Code 8480719090 Production Capacity 350sets /YearProduct Description

MELEEMOULD CO.,LTD

Plastik molding in moulding for baby use tooling.Baby seat molding,Baby seat tooling,injection molding for baby seat tooling

Detail description of PLASTIC cover Mold/Mould, injection cap mould,MOLD,Plastik injection molding for baby seat tooling

Plastic cap mould/mold. Injection cover mould.

Product Name: Plastic cover mould/mold

Product material: ABS, PP, PE or as per customer requirement.

Cover Mold/Mould cavity: As per customer requirement

Cover Mold/Mould size: Depends on your design.

Cover Mold/Mould material: P20, 718...

Cover Mold/Mould life: 800k shots

Runner system: Cold runner

Cover Mold/Mould features: Good quality

Injection cycle time: 20seconds

Tooling time: 25days

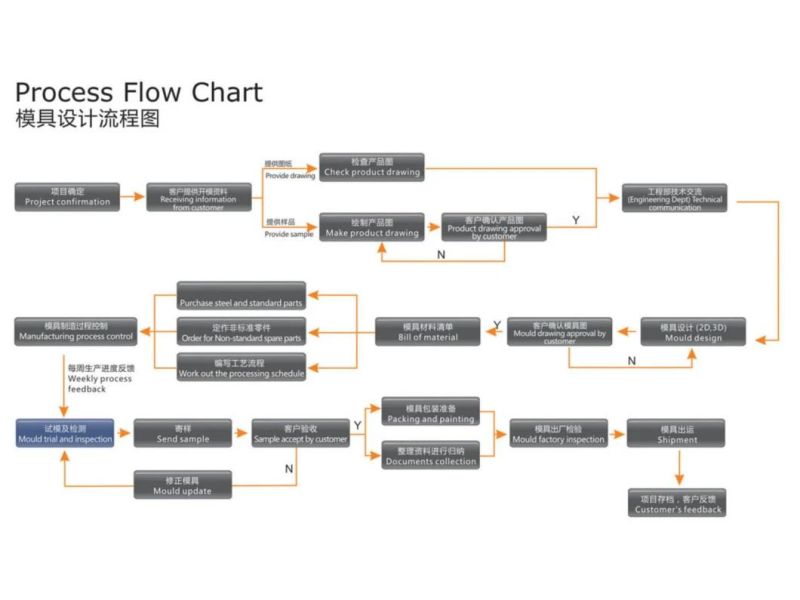

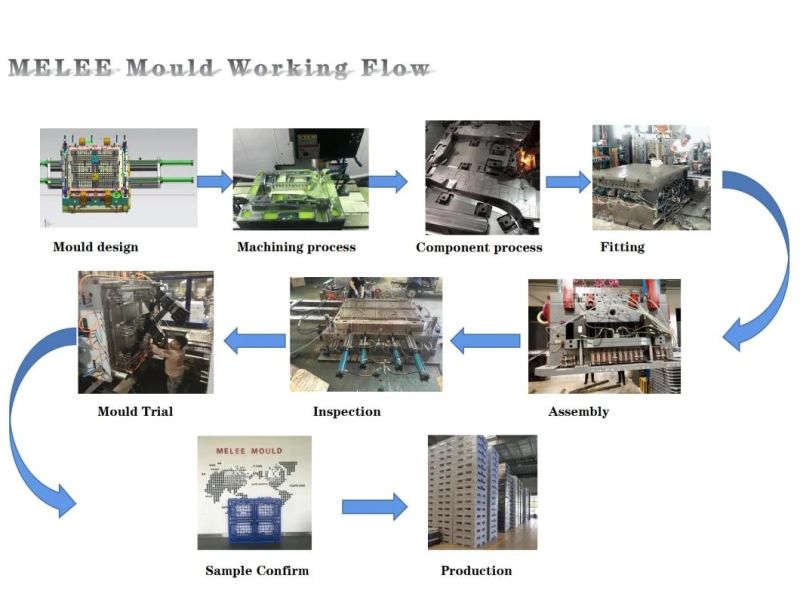

MELEE MOULD Co., Ltd service process

1. Design/sample: Product, mould, etc.

2. Discussion: Mould material, cavity number, price, runner, payment, etc.

3. Order placed: According drawing or your samples.

4. Design mould: We will send mould design to customer for confirmation

5. Mould tooling: We start to make mould after mould design confirmed

6. Mould processing: Send pictures to customer every week for the customer to know the mould processing.

7. Mould shot trial: Send mould shot trial samples to customer to confirm mould quality

8. Delivery: Ship mould after mould quality confirmed.