Plastic CD Case Box Injection Mould

Green Vitality Industry Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:PE

- Mould Cavity:Single Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Heat Treatment

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use

Base Info

- Specification:As per request

- Transport Package:Ply Wood Box

- Manufacturing Experience:25 Years

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Mobile

- Design Software:AutoCAD

- Runner:Hot Runner

- Model NO.:GV-mold

- Trademark:GVI

- Origin:China

- HS Code:8480710090

- Production Capacity:500 Sets Per Year

Description

Company Profile:

With 25 years experience in custom tooling and injection molding, we have become a good mold maker in manufacturing all kinds of plastic injection molds and molding parts.

90% of our molds are exported to more than 30 countries in Europe, North America, South America, Mid-east and Australia.

With scientific mold design, advanced technology, careful manufacturing and humanized service, Green Vitality can achieve and exceed customer's expectation. We have experienced mold makers. They are familiar with HASCO, DME etc standard mold components. They are well trained to operate each process of mold manufacturing and strictly control the manufacturing time for delivery guarantee.

We own modern Japanese management and advanced mold process equipment. The equipment enables us to provide our customers with special solution of tight machining precision and punctual delivery.

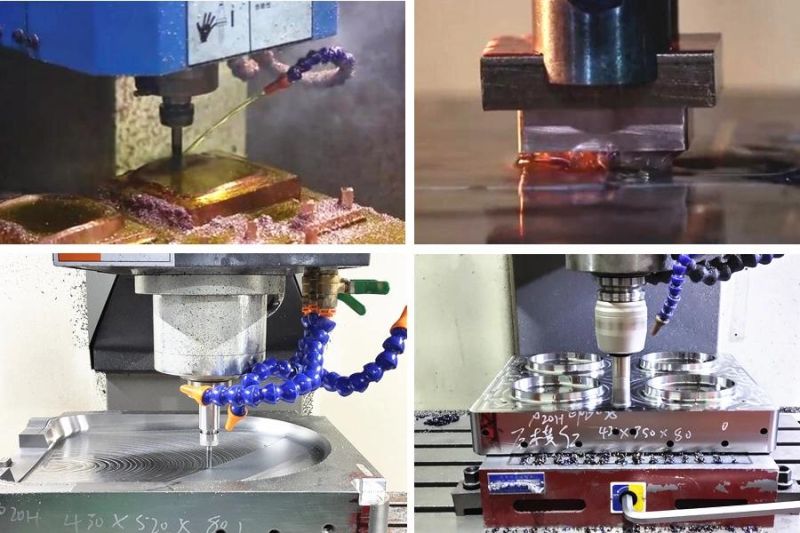

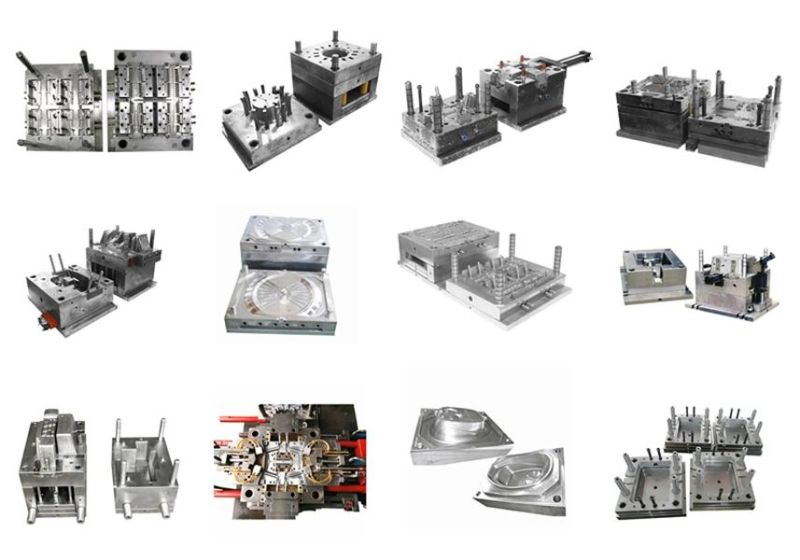

Mold Show:

Our tooling shop owns precision manufacturing equipment and skillful workers. We design and make molds depending on your annual production requirements.

To improve the manufacturing ability, new advanced technology and machines are introduced into our factory. Now our mold manufacturing ability is compliant with the international standards of mold industry.

Injection Parts Show:

We serve a broad range of customers in the field of automotive industry, electronic and electrical appliances, concerning connector molding parts, auto parts, medical parts and other tooling, etc.

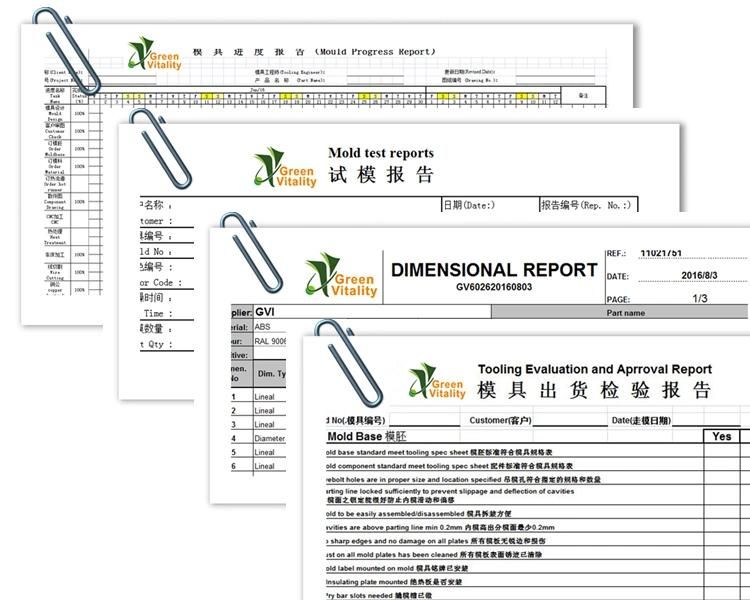

Quality Control

Quality control is the major section of each machining process in Green Vitality. Moreover, the quality control procedure and management system are strictly carried out according to ISO9001:2015 system.

In-process inspection procedure, self-owned accurarte measuring & testing equipment allow our QC team to check all components after machining.

- Quality inspection guidelines are tailored to meet specific customer requirements.

- Written inspection reports and clients specification are retained electronically.

- All ISO documents have been written and approved by qualified department managers.

Why choose us?

* Supply molds and products to over 30 countries.

* Have professional sales team with good English capabilities and communication skills.

* Offer OEM/ODM service.

* Provide value-added and one-stop service from plastic injection mold design to delivery.

* Ensure high quality with professional design team, project engineer, QC and R&D teams.

* Offer in-house mold design and building capabilities.

* Protect your idea and design through confidentiality agreement.

* Provide out-source service of dustless auto painting, electroplating, silkscreen with our partner factories.

* Make prototype 3 - 7 days.

* No MOQ limited and prompt delivery.

* Reach airport or sea port within one hour, near Hong Kong.

Interview us for your next project.

We can provide a rewarding partnership for your tooling and plastics requirements.