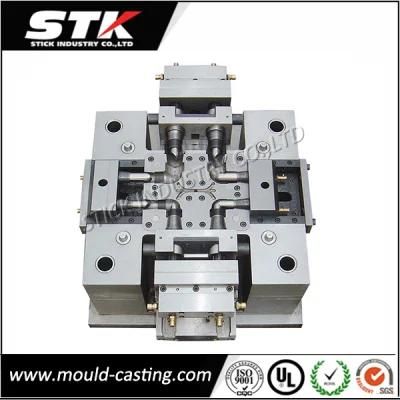

Hot Runner Plastic Injection Mold

Xiamen Stick Industry Co., Ltd.- Mould Base:Lkm , Hasco & Dem Standard

- Main Processing Equipment:Main Processing Equipment

- Plastic Material:ABS, PP, PE, Pet, EVA, PMMA, PC, PU etc

- Core and Cavity Material:718, 718h, S136, Nak80, P20, SKD61 etc

- Export Markets:Global

- Mould Material:H13 Steel Core & 45 Steel Frame

Base Info

- Trademark:STK or customized

- Specification:ISO 9001: 2000, SGS

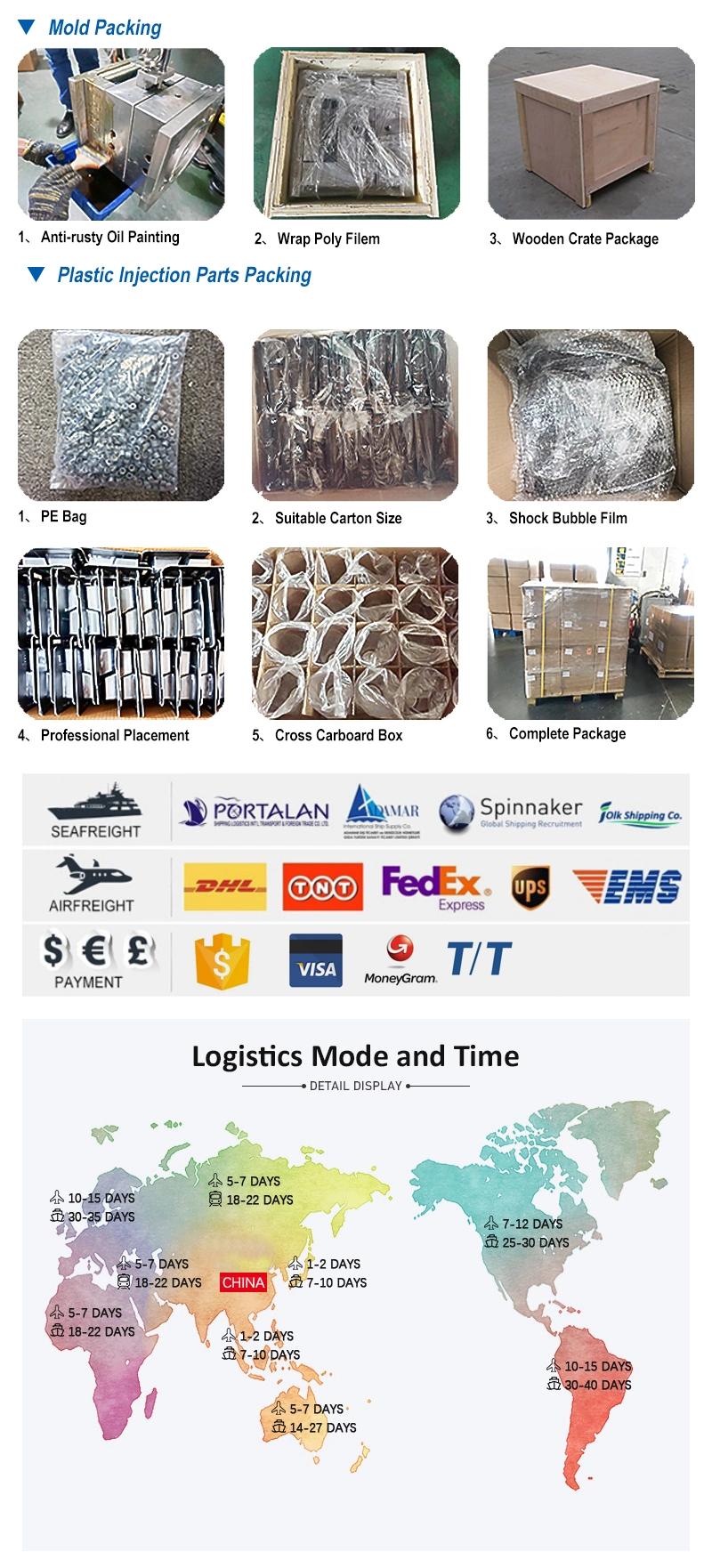

- Transport Package:Wood Crate for Mould, Carton for Finished Parts

- Value-Added Service:Polish, Texture, Painting, Screen-Printing

- Application:Plastic Injection Moulds

- Surface Treatment:EDM & High Polish

- Mould Cavity:Single & Multi- Cavity

- Model NO.:STK -MP0022

- Origin:Xiamen, Fujian, China

- HS Code:84679900

- Production Capacity:50 Sets, Month

Description

Basic Info.

Model NO. STK -MP0022 Mould Cavity Single & Multi- Cavity Surface Treatment EDM & High Polish Application Plastic Injection Moulds Value-Added Service Polish, Texture, Painting, Screen-Printing Transport Package Wood Crate for Mould, Carton for Finished Parts Specification ISO 9001: 2000, SGS Trademark STK or customized Origin Xiamen, Fujian, China HS Code 84679900 Production Capacity 50 Sets/ MonthProduct Description

Hot runner plastic injection mold --- Plastic injection mould1.Mould Cavity:Single or multi-cavities

2.Runner:Cold or Hot

3.Mould life:500000-1000000 shots

4.Material:Steel, steel alloy such as P20, 8074, 2083 or NAK-55

5.Mould base:LKM, FUTA, HASCO, DME, etc.

6.Production Leadtime:3-6 weeks depending on the complexity of drawings.

| Place of Origin | Xiamen, China |

| Brand Name | STICK INDUSTRY |

| Shaping Mode | Plastic Injection Mould |

| Product Material | Steel |

| Plastic Material | PP,PC,PA,PA6,ABS,PET,PVC,POM,.etc |

| Gate System | Cold Runner/Hot Runner |

| Ejection | Pin/Stripper Plate.etc |

| A.B plate | 1.1730/P20.etc |

| Tool Life | Prototype, 50-500K shots |

| Mold Base | LKM stand moldbase + copy HASCO components |

| Cavity & Core | 718, 718H, S136, NAK80, P20, SKD61 etc. |

| Surface Finish | Polish/Texture/Heat Treatment.etc |

| Cavities | Single/Multiple/Family mold Lead Time: 3~6 weeks |

Plastic Injection Parts Show

Production Process

Product Range

Company Profile

We believe that the best way to ensure our success is by providing our customers consistent quality in a timely fashion and at a fair price.

Stick Industry was established in 2004, with factory located in Haicang district, Xiamen city, South East of China.The company has been in business for over 15 years, beginning as a small plastic mold and die casting mold workshop growing into an industrial leading, multi-plant molder with factory size over 10000 square meters and employees about 150.

Conveniently located in the south of China, our ISO 9001-2015 Certified facility economically services markets throughout the world including USA, Russia, Canada, Mexico, Brazil, Germany, Spain, Italy, Poland etc

In addition to outstanding growth in our die cast and injection molding department, our secondary machining operations have continued to grow to meet the varied needs of our customers, including:Drilling, tapping, turning, boring, milling, sanding, shot blasting, vibratory finish, and more.

From concept to final production, from mechanical and electronic design to components sourcing, and from prototype manufacturing to mold design, our engineer team can jump in at any stage to complete your valuable project on time.

Our service include:Moulds, plastic injection molding, Aluminum/Zinc Die casting, CNC Machining, Sheet Metal Forming, Surface Treatments, Assembly and packaging.

Packing & Shipping

Packing & Shipping  RFQ

RFQ 1. Are you trading company or manufacturer ?

We are factory. We are experienced manufacturer, have our own factory and warehouse.

2. How long is your delivery time?

A: Generally it is 20-30 days for mould Manufacturing.15-30 days for the OEM Parts, it is according to quantity.

3: I have no 3D drawing, how should I start the new project?

A: You can provide us a sample, we will help finish the 3D drawing design.

4.Do you provide samples ? is it free or extra ?

Yes, we could offer the sample for free charge but do not pay the cost of freight.

5.What is your terms of payment ?

Our preferential payment term is T/T

Mould Tooling : 50% down payment, 50% balance against the sample approval.

Mass Production: 50% down payment , 50% against the B/L copy

6.What do we need if you want a quote?

Please kindly send us your 2D & 3D drawing of your product.

Drawing format (CAD/PDF/DWG /IGES/STEP/ X_T etc.)

The detail specificationsneed as follows :

1. Material 2. Surface treatment 3. Estimated production volume 4.Any special packing

7.How do I know about the production ?

We will double confirm your requirements and send you the samples before the mass production . During the mass production , we will keep you informed of any progress.Besides, we will do 100% quality inspection before shipment

8.How do we know about the delivery status ?

We will immediately inform you the tracking number once we get it from shipping agent. Besides, we will update the latest shipping information.

We will pay great attention to your any question or enquiry.

If any questions, please feel free to contact us at any time.

Tel:86-592- 5811670

Fax:86-592- 5209672

Ms. Cherry Cai