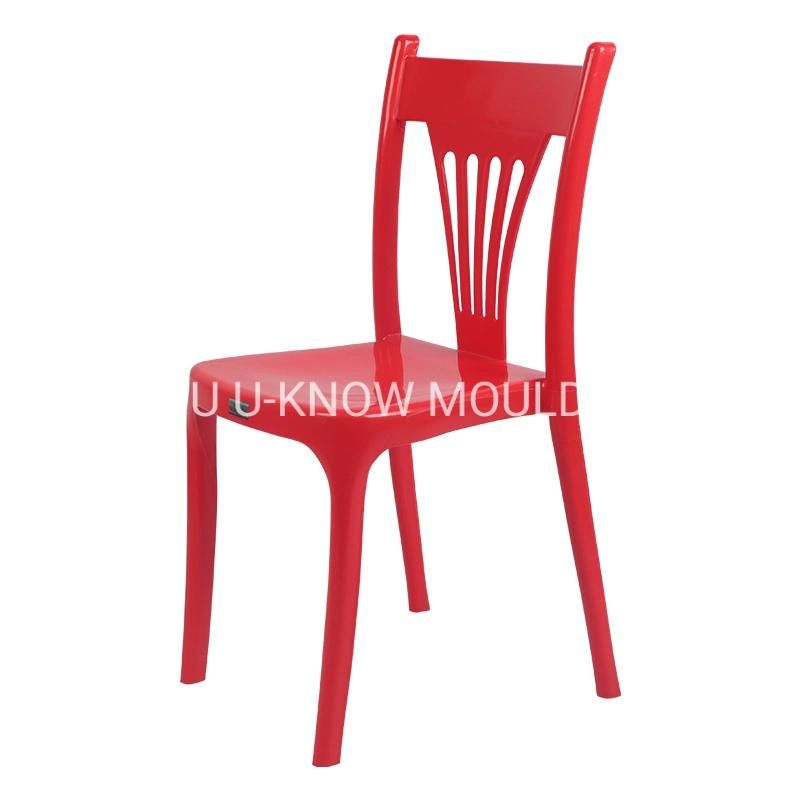

Customized Plastic Hollow out Back Chair Injection Mould Plastic Armless Chair Mold

TAIZHOU U-KNOW MOULD CO., LTD.- Plastic Material:PC

- Mould Cavity:Single Cavity

- Surface Finish Process:Sand Blasting

- Shaping Mode:Injection Mould

- Process Combination Type:Single-Process Mode

- Application:Home Use

Base Info

- Specification:1100*1100*900MM

- Transport Package:Wooden Box

- Customized:Customized

- Standard:HASCO

- Certification:TS16949, CE, ISO, FDA

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Trademark:UKNOW

- Origin:China

- HS Code:8480719090

- Production Capacity:500 Sets,Year

Description

About US

How to go to your factory?

You can come to our city by flight, bus or train.

It takes 2 hours by flight from Guangzhou to our city.

It takes 3.5 hours by train from Shanghai to our city.

It takes 1 hour by bullet train from Ningbo to our city.

Our Services

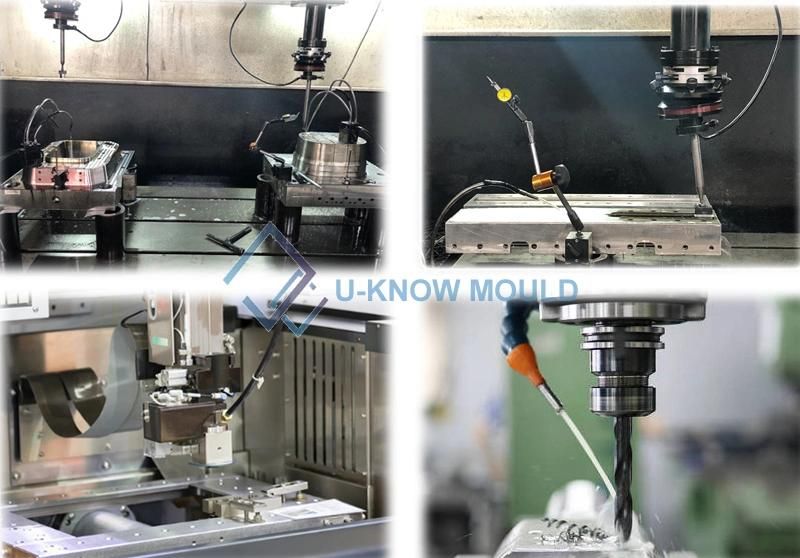

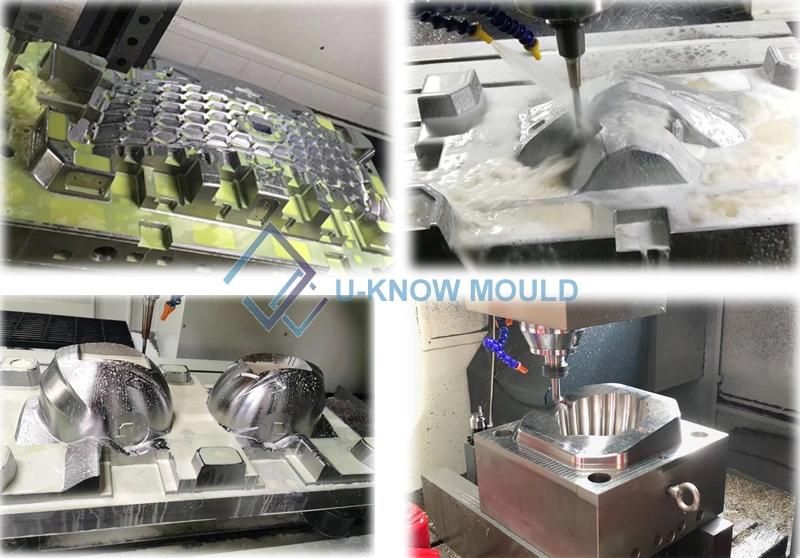

1. Our company specializes in plastic injection molding, mold manufacturing and product assembly.

2. We can produce parts of any size and perform post-processing, assembly or packaging according to customer requirements.

3. We can use your existing mold or produce a mold in our factory. With 20 years of experience, we can handle any of your projects.

4. We can also assist you in the special design of the product and then produce it by injection molding.

5. Processing method: processing according to the provided drawings

6. Standard or non-standard: We process standard and non-standard forgings at the same time.

7. We can provide samples before the big order.

8. After-sales service: All castings will be strictly inspected. If defects are found, we will produce new ones or make up for them.

Packaging & Shipping

- Mould surface of core and cavity will be covered by antirust

- The mould surface will be covered by butter

- The mould will be packed by plastic membrane

- The mould will be put into wooden case

- Some other spare parts will be put into the wooden case together with mould, there are lifting bolt, water nozzle, water hose. Ejector-pin etc.

- Delivery Time:We will delivery injection mould in 45-60 days