Plastic Arm Chair Mould/Plastic Outdoor Chair Mold

TAIZHOU U-KNOW MOULD CO., LTD.- Process Combination Type:Single-Process Mode

- Plastic Material:PP,PE,ABS,PC,Ect.

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Household Appliances, Furniture, Commodity, Home Use

Base Info

- Specification:45#, P20, H13, 718, 2738, NAK80, S136etc.

- Transport Package:Wooden Case

- Customized:Customized

- Standard:HASCO

- Certification:ISO

- Installation:Semi Fixed

- Design Software:Ug,PRO-E,CAD

- Runner:Hot,Cold Runner

- Model NO.:UKC001

- Trademark:UK

- Origin:China

- HS Code:8480719090

- Production Capacity:300 Sets,Year

Description

Basic Info.

Model NO. UKC001 Runner Hot/Cold Runner Design Software Ug/PRO-E/CAD Installation Semi Fixed Certification ISO Standard HASCO Customized Customized Transport Package Wooden Case Specification 45#, P20, H13, 718, 2738, NAK80, S136etc. Trademark UK Origin China HS Code 8480719090 Production Capacity 300 Sets/YearProduct Description

Company Information:

TAIZHOU U-KNOW Mould Co.,Ltd is an enterprise specialied in designning and manufacturing the various kind of injection moulds.U-KNOW MOULD provide the moulds and the plastic products to lots of areas all over the world,such as Southeast Asia,Middle East,Russia,Brazil,Poland,Romania,etc.

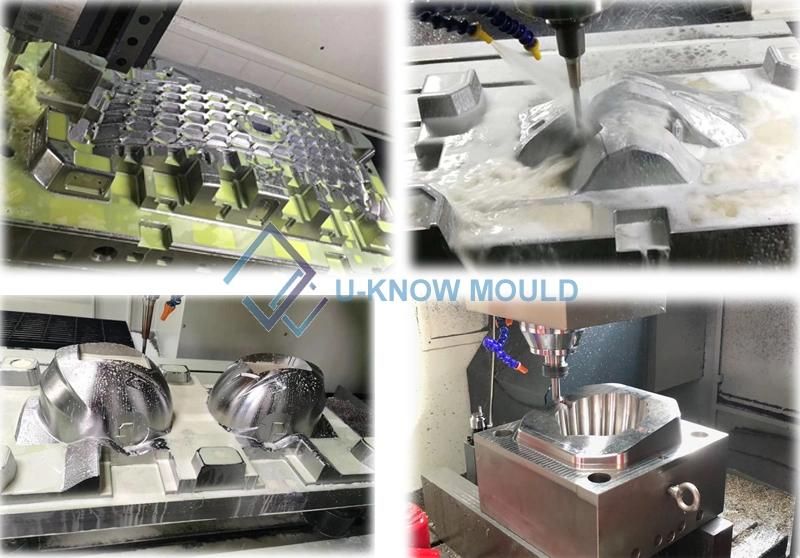

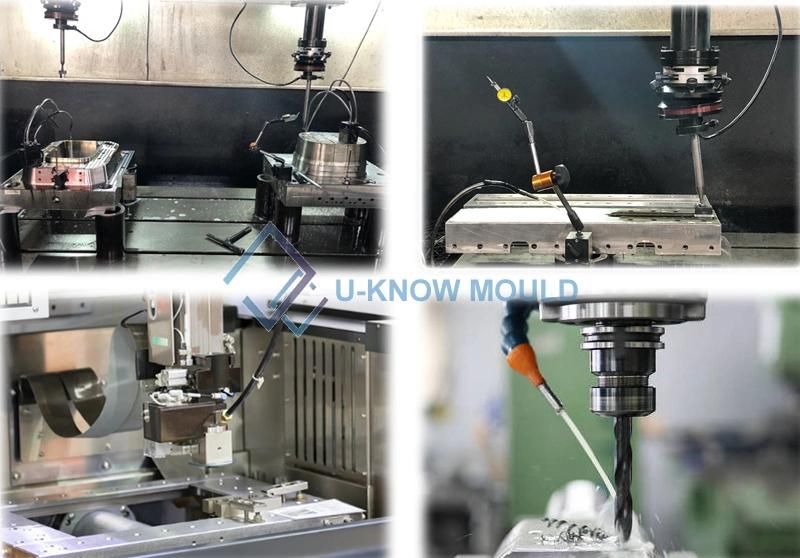

U-KNOW MOULD owns strong research & develop team and full set production equipment:professional CAD/CAM computer aided design system,Multiple specifications high speed CNC maching center,Closing service,Mirror EDM,Drilling machine,Flat grinder and 120T-2100T injection machines.

U-KNOW MOULD has passed ISO9001 certification and has a number of design patents.In recent years,U-KNOW MOULD focused on developing,researching,designing and production of integral molding mould with gas assited injection,which has won praises from customers.

Our company sincerely welcomes new and old clients for consultation and cooperation!

WHAT SERVICE WE CAN PROVIDE:

Idea design /Rapid prototype/3D print/Mold design

Injection mold

1. In 24 hours give quotation.

2. Provide all technology support

3. Help customer do design work

4. Build friendship with customer

5. Find solutions for customer's trouble

6. Grow up with customer together

Product Detail:

| Product name | Plastic Arm Chair Mould |

| Product material | PP, PE, ABS, PC,etc. |

| Mould steel | 45#, P20, H13, 718, 2738, NAK80, S136etc. |

| Mould base | LKM, HASCO,etc. |

| No. of Cavity | single |

| Hardness of mould steel | 48-52HRC |

| Hardness of Wear Parts | 55-60HRC |

| Ejector system | stripping plate, angel pin, ejector pin etc |

| Surface finished | Polish,texture |

| Mold life | 500, 000shots |

| Runner system | Cold &Hot |

| Tool lead time | 65 work days |

| Packing | Standard wooden case |

| Payment | T/T L/C |

Our Sample Room:

Packaging & Shipping

Anti-rust oil is painted first, then plastic film, and finally wooden case.

Sent together with the mould:

a) Mould manual instruction

b) Engineering drawing in flash disk

c) One more set of mould spare parts: heater, ejector pin, bush, water nozzle, water pipe, hanging ring.

FAQ:

1.

Q: Does your company make mould by yourself?

A: Yes, we have more than 20 years mould manufacturer experience.

2.

Q: Can you provide the steel certificate and heat-treatment certificate?

A: Yes, We can provide steel certificate or hardness certificate to prove.

3.

Q: How do you pack the china plastic mould?plastic injection mold packaging

A: We pack the plastic mould with wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid moisture.

Third step: We put this plastic film packed mold in a wooden box, and fix it avoid any movement.

4.

Q:What is your turnaround time for injection mold building?

A:Usually 3-5 weeks, it also depends on mold size and structure complexity. We can overwork for your urgent project to shorten the delivery