Plastic Mold for TV Enclosure-Television Shell Mold- TV Frame Mold

Green Vitality Industry Ltd.- Process Combination Type:Injection Cavity

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Polishing

- Application:Household Appliances, Furniture, Commodity, Electronic, Home Use

Base Info

- Steel Suppliers:Assab, Daidao, Lkm, Buderus,Baogang, Fushun, etc

- Cycle Time:15-30s

- Injection Machine:300-400t

- Injection System:Edge Gate, Side Gate, Sub Gate, Pin Point Gate

- Core and Cavity Steel:P20, H13, 718h, Nak80, SKD61,2316, 2738, 2344, S13

- Mold Base Steel:S45c,S50c,P20, Lkm etc

- Mold Delivery Time:45-50days

- Mold Life:5,000,000-1,000,000shots

- Tooling Steel:S136 H13 718h P20 Nak80

- General Material Used:PC PP ABS

- Standard:HASCO

- Customized:Customized

- Certification:ISO

- Installation:Fixed

- Design Software:AutoCAD

- Runner:Hot Runner

- Model NO.:home appliance mold

- Hot Runner Brand:Synventive, Yudo, Incoe, Hasco, Dme, Moldmaster, E

- Transport Package:Pry Wood Box

- Specification:Customized

- Trademark:GVI

- Origin:China

- HS Code:8480710090

- Production Capacity:500 Sets ,Year

Description

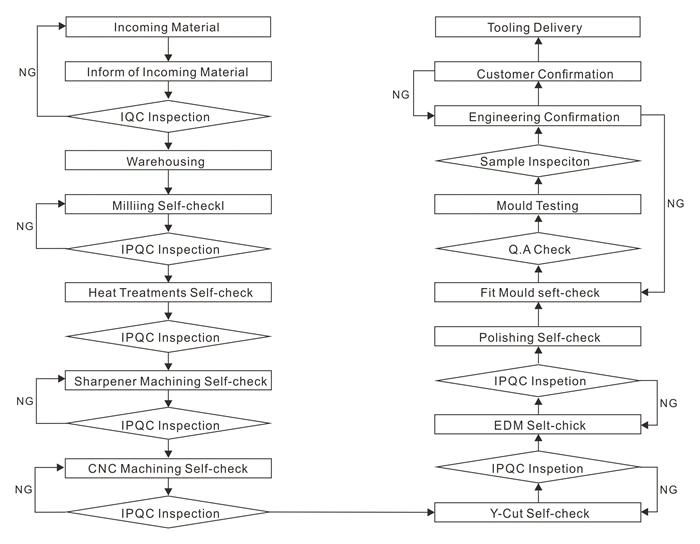

Operation Flow:

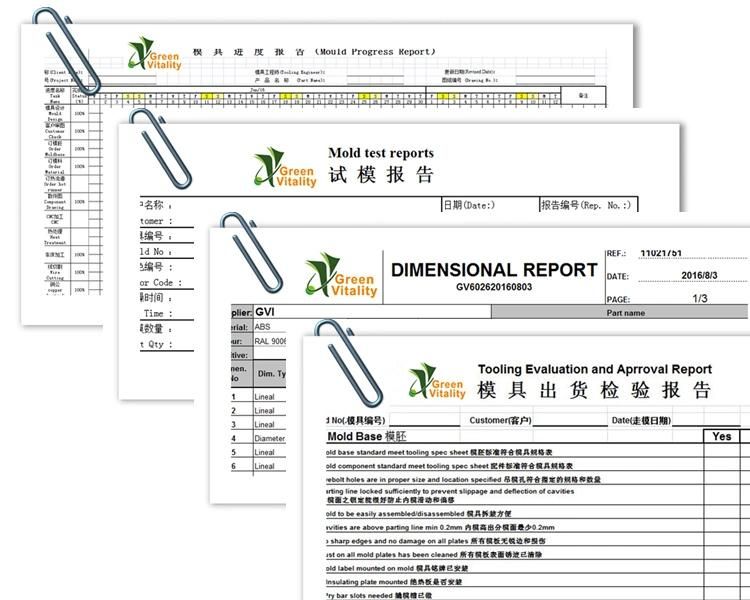

Green Vitality Mold uses professional form and graphics such as BOM of mold, weekly report with pictures, injection parameter report and dimension report to manage all of projects running process.

Commitment to Quality:

- Continually maintaining and improving the effectiveness of our quality management system.

- Periodic review of current quality policy and objectives to ensure its effectiveness and suitability.

- Quality First and Service First is our pledge. In order to serve and support our clients better, we would establish a special team called Technology and Cost Team. So Best Practice (top quality and competitive price) will be submitted to you in the shortest time. Green vitality sincerely welcomes you and hopes to be the most suitable and steadiest partner of you.

- We promise, and we do !

Julia Zhu

Green Vitality Industry Co., Ltd

Web: http://greenvitality.en.made-in-china.com