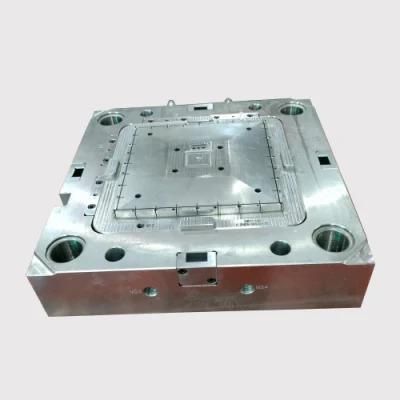

Custom 300K Cycles Plastic Injection Tooling with E420 Mold Materials

Dongguan Howe Precision Mold Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:HDPE

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Car, Furniture, Electronic, Hardware

Base Info

- Surface Treatment:Polishing, Heat Treatment, Plating, Machining

- Molding Material:PC,PC,ABS,PC,PMMA,etc

- Sprue Gate:Pin Point Gate, Edge Gate,etc

- Mold Life Time:300K~1000K Times

- Mold Cavity:Single Cavity , Family Molds , Multi Cavity

- Process:CNC Turning, Drilling, Milling, Punching.....

- Name:Plastics Injection Mold

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Fixed

- Design Software:Pro-E

- Runner:Hot Runner

- Model NO.:HW-1135

- Lead-Time:7-14 Days for Samples, 25-40 Days for Mould

- Experiences:More Than 12 Years Experience

- Transport Package:Wooden Cases,Air,Sea

- Specification:Custom

- Trademark:HOWE or Custom

- Origin:China

- HS Code:84807100

- Production Capacity:40sets,Month

Description

Howe Mold was founded in 2010 to produce top class injection molds for the plastics industry. This company has an extensive background in building tools for the electronics, medical, computer, agricultural, automotive, and communications industries. Our customers turn to us to design and build various types of steel and aluminum, single or multi-cavity, molds for injection, structural foam, rim, blow, gas assist and structural web processes. We also design and build aluminum injection molds for limited production runs.Today we serve customers in the computer, automotive, medical, material handling, electronics, and pet industries.

Specializing in three main areas:

1. Manufacture of custom prototype and production injection molds from your part data to a complete mold in just weeks.

2. Rapid turnaround mold repairs, which allow you to get your tools back into production quickly.

3. High quality machining, grinding, CNC machining, EDM and CNC EDM.

Quote:According to sample, drawing and specific requirement.

↓

Discussion:Mold material, cavity number, price, runner, payment, etc.

↓

S/C Signature:Approval for all the items

↓

Advance:Pay 40% by T/T

↓

Product Design Checking:We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report

↓

Mold Tooling:We start to make mold after mold design confirmed

↓

Mold Processing:Send report to customer once each week

↓

Mold Testing:Send trial samples and try-out report to customer for confirmation.

↓

Pay 30% by T/T on trial samples

↓

Mold Modification:According to customer's feedback

↓

Balance settlement:30% by T/T after the customer approved the trial sample and mould quality.

↓

Delivery:Delivery by sea or air. The forwarder can be designated by your side.