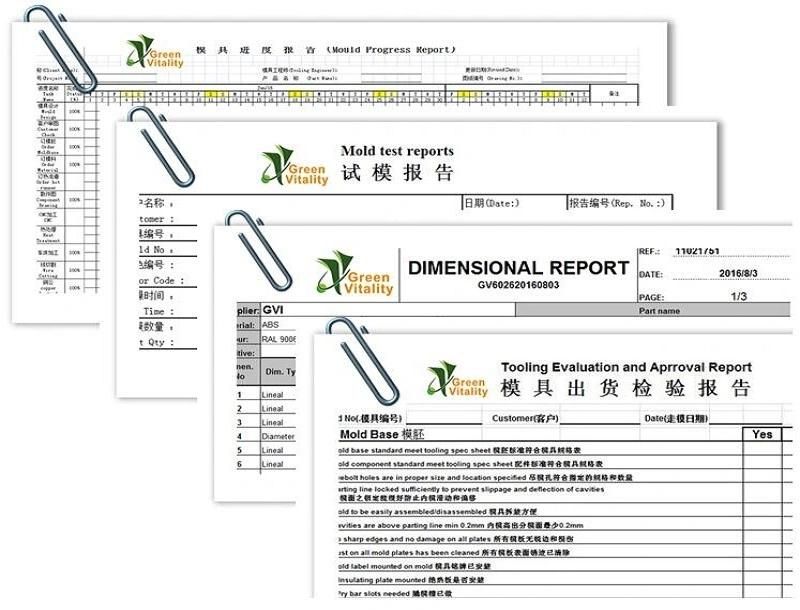

Plastic Injection Mould for Clear Disposable Coffee Tea Icecream Spoon

Green Vitality Industry Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

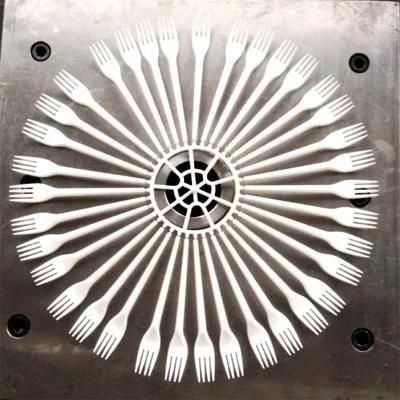

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Household Appliances, Commodity, Home Use

Base Info

- Specification:customized

- Transport Package:Free-Fumigation Three-Plywood Case

- Customized:Customized

- Standard:HASCO

- Certification:ISO

- Installation:Fixed

- Design Software:AutoCAD

- Runner:Cold Runner

- Model NO.:gv-mold

- Trademark:GV

- Origin:Guangdong, China

- HS Code:8480719090

- Production Capacity:500sets Per Year

Description

Basic Info.

Model NO. gv-mold Runner Cold Runner Design Software AutoCAD Installation Fixed Certification ISO Standard HASCO Customized Customized Transport Package Free-Fumigation Three-Plywood Case Specification customized Trademark GV Origin Guangdong, China HS Code 8480719090 Production Capacity 500sets Per YearProduct Description

Plastic Injection Mould for Clear Disposable Coffee Tea Icecream Spoon| Mold Description | spoon mould |

| Mold Standard | DME or HASCO |

| Mold Base | LKM,DME,HASCO,FUTABA |

| Cavity /Core steel | H13,S-7,S136,SS420,NAK80,P20 and other material as requirement |

| Hot Runner | Yudo |

| Cavity | Multi or single cavity |

| Gate type | Side gate,Sub gate,Pin point gate,Edge gate etc |

| Hydraulic cylinder | PARKER, TAIYO, STAUBU, JUFAN |

| Mold components | DME, Progressive, PCS, Punch, Royal, etc |

| Steel Treatment | Heat Treatment, Nitriding, Chrome Plating |

| Surface finish | SPI standard, VDI EDM, Texture, etc |

| Texture | Mold-tech, Yick Sang, Ni Hong ,Tanazawa etc |

| Plastic Material | PP, PC, ABS, PE, HDPE, PET, POM, PMMA, PA(GF), PBT(GF), PVC, PPS,etc |

| Product weight | 5.0g~15kgs |

| Mould Life | 0.3 Million Shots- 1Million shots |

| Delivery Time | 4Weeks T1 samples , exact time depends on Mould Complexity |

| Packaging | Free-Fumigation Three-Plywood case for moulds, cartons for parts |

| Design software | CAD,UG, Pro E, Solidworks |

| Value-added service | Dust-free Spraying, Silk-screen Printing, Ultrasonic Welding, Thermal Bonding, Assembling, Prototype |

| Service area | Transparent, Over mold, double color, air assistant forming, deep barrel, Design R&D, Assembly |

| Our Capability | Auto, Aerospace, Household, Electrical, Industrial, Medial, Toys, Office, Cosmetic, Outdoor, OA Equipment etc |

EQUIPMENT LIST

About Us:

Green Vitality has over 25 years of experience making high-quality injection moulds and producing high-quality plastic injection molded components. Our factory has passed ISO 9001:2015, ISO 14000 and TS16949 are also in our agenda. We also offer assembly and packaging services. This capacity ensures we can fulfill multiple high-volume orders quickly.

Our capabilities include:

- Prototyping

- Multi-cavity Mold

- Two-Shot Mold

- Insert molding

- Overmolding

- Mold maintenance and repair

- High-volume order production

- Finishing services (Ultrasonic Welding, Sonic Welding, Silk Screening,pad printing, Painting, in-mold decorating, labeling)

- Product assembly

Our advantage and service:

1. We are a mold manufacturer,so we quote the first-hand quotation, no middleman.

2.We have the self-management import and export license.

3. We have been in the mold industry for 25 years, all of our sales staff have more than 5 years of mold industry experience.

4. All of our molds quality based on Europe standard and American standard.

5. Prompt afer-service. We provide lifetime after-sale technical support.

6.One-stop service and No MOQ limited.

Sample Show

Production process

Your OEM and ODM model are welcomed.

* Customize drawings or design or idea can be realized.

* Design the drawings according to your drawing, sketch or samples.

* Small prouction orders are also acceptable.

* High quality and short lead time, professinal and cost-saving mold solution supplier.

We manufacture, assemble, pack, store and distribute

Once your semi-finished products have been manufactured, we are able to assemble your items, and also complete the production cycle through to final packaging, ready for distribution to anywhere in theworld.

We have the capability to add additional components which we either produce or source from worldwide partners, assemble and package your products to complete the manufacture of your items.

This is an one stop service which is hard to be beat.

We hope you to be able to concentrate on what you are good at, and leave the rest to us!

Highlights

General assembly, by individuals and on production lines by teams.

Hotplate welding.

Heat stacking of inserts.

Ultrasonic welding assembly of plastic components.

Manual assembly of components to build up subassemblies or finished assemblies,

Packing.

"Wonderful Design + Professional Mold maker = Perfect Product"

You will enjoy our good service and cost-effective solutions from design to delivery.