Custom Injection Mould for Auto Plastic Products

Nantong Ulilong International Trade Co., Ltd.- Plastic Material:PBT-GF10

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Process Combination Type:Single-Process Mode

- Application:Car

Base Info

- Transport Package:Anticorrosive Paint, Plastic Film, Wooden Case.

- Plastics Industry:Automotive Plastic Mould

- Customized:Customized

- Standard:HASCO

- Installation:Fixed

- Certification:ISO

- Design Software:Pro-E

- Runner:Hot Runner

- Model NO.:Auto Parts Mould

- Specification:According to drawing or sample

- Trademark:Ulilong

- Origin:China

- HS Code:8480719090

Description

Basic Info.

Model NO. Auto Parts Mould Runner Hot Runner Design Software Pro-E Installation Fixed Certification ISO Standard HASCO Customized Customized Plastics Industry Automotive Plastic Mould Transport Package Anticorrosive Paint, Plastic Film, Wooden Case. Specification According to drawing or sample Trademark Ulilong Origin China HS Code 8480719090Product Description

Plastic injection mold / mould for Auto Parts| Mold Base | LKM, HASCO, DME or as per your requirement. |

| Mold Material | P20, NAK80, SKD61, S136, H13, 718, 45# and so on. |

| Product Material | ABS, PP, PS, PA, PE, POM, PMMA , PBT+GF and so on. |

| Brand | ULILONG |

| Runner System | Cold/Hot runner |

| Mold Running | Automatic |

| Mold Cavity | Single or Multi. |

| Mold Life | 300,000-500,000 shots |

| Design Software | CAD, Pro-E, UG, Solidworks. |

| MOQ | 1 set |

| Mold Lead Time | an ordinary mold takes about 35-45 days |

| Mold payment Term | 50% T/T in advance, balance 50% after sample approved. |

| Packaging | Anticorrosive paint -- plastic film -- wooden case or as per your requirement. |

| Port of Loading | Shanghai port |

Related plastic part

About Us

Ulilong is a plastic part manufacturer and injection mold maker from China. We specialize in the design and manufacturing of custom injection molded parts at good quality and competitive price. We have our own factory and also have more than 6 reliable partners do the manufacturing works for us. We always choose the most fitful one for your project, and ensure top quality, a shortened lead time and a quick resolution to any issues.

We have professional engineering team who are good at mold design and molding process. Our teams are able to develop the simplest or the most complex multi-cavity molds in a reasonable time. We also offer repair and engineering changes on all plastic injection molds.

Our another product line is carbon brush and brush holder.

Our Service

Ulilong provides one-stop-service for plastic mold and plastic product customizing works. We provide mold design, precision plastic mold making, custom plastic injection molding. And we also help with plastic injection mold repair and revisions. Equipped with advanced technology and machining, our engineering has the knowledge and experience to produce mold of good quality.

We can help you with a variety of plastic injection mold design, including:

Single/Multi-Cavity Molds

Family Molds

2-Shot Molds

Rotary Molds

Insert/Over Molds

We also help you with:

Plastic Injection Mold Repair

Plastic Injection Mold Revisions

We can provide you with cost-effective solutions and a short lead time.

Why Choose Us

1. We've produced hundreds of plastic injection molds for a global customer base. We are able to develop the simplest or the most complex multi-cavity molds.

2. Good quality, Reasonable price, Timely response, On time delivery, Good after-sales service.

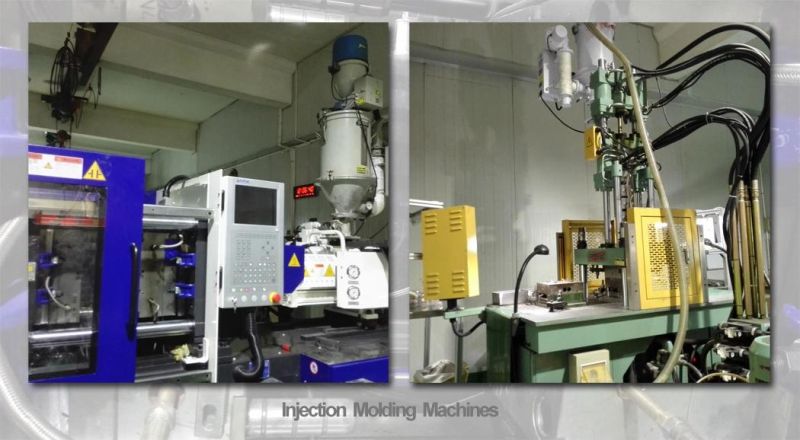

Plastic Injection Molds Show

Plastic Parts Show

We welcome any size order and work hard to provide you with immediate service, good quality products and competitive pricing.